1. The INI File Components

A typical INI file follows a rather simple layout that includes;

-

comments

-

sections

-

variables

Each of these elements is separated on single lines. Each end of line or newline character creates a new element.

1.1. Comments

A comment line is started with a ; or a # mark. When the ini reader sees either of these marks at the start a line, the rest of the line is ignored by the software. Comments can be used to describe what an INI element will do.

; This is my mill configuration file. # I set it up on January 12, 2012

Comments can also be used to turn off a variable. This makes it easier to pick between different variables.

DISPLAY = axis # DISPLAY = touchy

In this list, the DISPLAY variable will be set to axis because the other one is commented out. If someone carelessly edits a list like this and leaves two of the lines uncommented, the first one encountered will be used.

Note that inside a variable, the "#" and ";" characters do not denote comments:

INCORRECT = value # and a comment # Correct Comment CORRECT = value

1.2. Sections

Related parts of an ini file are separated into sections. A section name is enclosed in brackets like this [THIS_SECTION] The order of sections is unimportant. Sections begin at the section name and end at the next section name.

The following sections are used by LinuxCNC:

-

[EMC] general information

-

[DISPLAY] settings related to the graphical user interface

-

[FILTER] settings input filter programs

-

[RS274NGC] settings used by the g-code interpreter

-

[EMCMOT] settings used by the real time motion controller

-

[TASK] settings used by the task controller

-

[HAL] specifies .hal files

-

[HALUI] MDI commands used by HALUI

-

[APPLICATIONS] Other applications to be started by LinuxCNC

-

[TRAJ] additional settings used by the real time motion controller

-

[AXIS_n] individual axis variables

-

[EMCIO] settings used by the I/O Controller

1.3. Variables

A variable line is made up of a variable name, an equals sign (=), and a value. Everything from the first non-white space character after the = up to the end of the line is passed as the value, so you can embed spaces in string symbols if you want to or need to. A variable name is often called a keyword.

MACHINE = My Machine

A variable line may be extended to multiple lines with a terminal backslash (\) character. A maximum of MAX_EXTEND_LINES (==20) are allowed. There must be no whitespace following the trailing backslash character.

Section identifiers may not be extended to multiple lines.

APP = sim_pin \ ini.0.max_acceleration \ ini.1.max_acceleration \ ini.2.max_acceleration \ ini.0.max_velocity \ ini.1.max_velocity \ ini.2.max_velocity

The following sections detail each section of the configuration file, using sample values for the configuration lines.

Variables that are used by LinuxCNC must always use the section names and variable names as shown. In the following example the variable MACHINE is assigned the value My Machine.

1.4. Custom Sections and Variables

Most sample configurations use custom sections and variables to put all of the settings into one location for convenience.

To use a custom section variable in your HAL file add the section and variable to the INI file.

[OFFSETS] OFFSET_1 = 0.1234

To add a custom variable to a LinuxCNC section simply include the variable in that section.

[AXIS_0] TYPE = LINEAR ... SCALE = 16000

To use the custom variables in your HAL file put the section and variable name in place of the value.

setp offset.1.offset [OFFSETS]OFFSET_1 setp stepgen.0.position-scale [AXIS_0]SCALE

|

Note

|

The value stored in the variable must match the type specified by the component pin. |

1.5. Include Files

An INI file may include the contents of another file by using a #INCLUDE directive.

#INCLUDE filename

The filename can be specified as:

-

a file in the same directory as the INI file

-

a file located relative to the working directory

-

an absolute file name (starts with a /)

-

a user-home-relative file name (starts with a ~)

Multiple #INCLUDE directives are supported.

#INCLUDE axis_0.inc #INCLUDE ../parallel/axis_1.inc #INCLUDE below/axis_2.inc #INCLUDE /home/myusername/myincludes/display.inc #INCLUDE ~/linuxcnc/myincludes/rs274ngc.inc

The #INCLUDE directives are supported for one level of expansion only — an included file may not include additional files. The recommended file extension is .inc. Do not use a file extension of .ini for included files.

2. INI File Sections

2.1. [EMC] Section

-

VERSION = $Revision: 1.3 $ - The version number for the INI file. The value shown here looks odd because it is automatically updated when using the Revision Control System. It’s a good idea to change this number each time you revise your file. If you want to edit this manually just change the number and leave the other tags alone.

-

MACHINE = My Controller - This is the name of the controller, which is printed out at the top of most graphical interfaces. You can put whatever you want here as long as you make it a single line long.

-

DEBUG = 0 - Debug level 0 means no messages will be printed when LinuxCNC is run from a terminal. Debug flags are usually only useful to developers. See src/emc/nml_intf/debugflags.h for other settings.

2.2. [DISPLAY] Section

Different user interface programs use different options, and not every option is supported by every user interface. The main two interfaces for LinuxCNC are AXIS and Touchy. There are several newer interfaces, like gmoccapy and gscreen. Axis is an interface for use with normal computer and monitor, Touchy is for use with touch screens. Gmoccapy can be used both ways and offers also many connections for hardware controls. Descriptions of the interfaces are in the Interfaces section of the User Manual.

-

DISPLAY = axis - The name of the user interface to use. Valid options may include: axis, touchy, gmoccapy, gscreen, keystick, mini, tklinuxcnc, xemc,

-

POSITION_OFFSET = RELATIVE - The coordinate system (RELATIVE or MACHINE) to show on the DRO when the user interface starts. The RELATIVE coordinate system reflects the G92 and G5x coordinate offsets currently in effect.

-

POSITION_FEEDBACK = COMMANDED - The coordinate value (COMMANDED or ACTUAL) to show on the DRO when the user interface starts. In Axis this can be changed from the View menu. The COMMANDED position is the position requested by LinuxCNC. The ACTUAL position is the feedback position of the motors if they have feedback like most servo systems. Typically the COMMANDED value is used.

-

MAX_FEED_OVERRIDE = 1.2 - The maximum feed override the user may select. 1.2 means 120% of the programmed feed rate.

-

MIN_SPINDLE_OVERRIDE = 0.5 - The minimum spindle override the user may select. 0.5 means 50% of the programmed spindle speed. (This is used to set the minimum spindle speed).

-

MAX_SPINDLE_OVERRIDE = 1.0 - The maximum spindle override the user may select. 1.0 means 100% of the programmed spindle speed.

-

DEFAULT_SPINDLE_SPEED = 100 - The default spindle RPM when the spindle is started in manual mode. if this setting is not present, this defaults to 1 RPM for AXIS and 300 RPM for gmoccapy.

-

PROGRAM_PREFIX = ~/linuxcnc/nc_files - The default location for g-code files and the location for user-defined M-codes. This location is searched for the file name before the subroutine path and user M path if specified in the [RS274NGC] section.

-

INTRO_GRAPHIC = emc2.gif - The image shown on the splash screen.

-

INTRO_TIME = 5 - The maximum time to show the splash screen, in seconds.

-

CYCLE_TIME = 0.05 - Cycle time in seconds that display will sleep between polls.

|

Note

|

The following [DISPLAY] items are used by GladeVCP, see the embedding a tab section of the GladeVCP Chapter. |

-

EMBED_TAB_NAME=GladeVCP demo

-

|

Note

|

The following [DISPLAY] items are for the AXIS interface only, see the AXIS GUI document for details. Many of them are used also from gmoccapy, see the gmoccapy document for details. |

-

DEFAULT_LINEAR_VELOCITY = .25 - The default velocity for linear jogs, in , machine units per second.

-

MIN_VELOCITY = .01 - The approximate lowest value the jog slider.

-

MAX_LINEAR_VELOCITY = 1.0 - The maximum velocity for linear jogs, in machine units per second.

-

MIN_LINEAR_VELOCITY = .01 - The approximate lowest value the jog slider.

-

DEFAULT_ANGULAR_VELOCITY = .25 - The default velocity for angular jogs, in machine units per second.

-

MIN_ANGULAR_VELOCITY = .01 - The approximate lowest value the angular jog slider.

-

MAX_ANGULAR_VELOCITY = 1.0 - The maximum velocity for angular jogs, in machine units per second.

-

INCREMENTS = 1 mm, .5 in, … - Defines the increments available for incremental jogs. The INCREMENTS can be used to override the default. The values can be decimal numbers (e.g., 0.1000) or fractional numbers (e.g., 1/16), optionally followed by a unit (cm, mm, um, inch, in or mil). If a unit is not specified the machine unit is assumed. Metric and imperial distances may be mixed: INCREMENTS = 1 inch, 1 mil, 1 cm, 1 mm, 1 um is a valid entry.

-

GRIDS = 10 mm, 1 in, … - Defines the preset values for grid lines. The value is interpreted the same way as INCREMENTS.

-

OPEN_FILE = /full/path/to/file.ngc - The file to show in the preview plot when AXIS starts. Use a blank string "" and no file will be loaded at start up. gmoccapy will not use this setting, as it offers a coresponding entry on its settings page.

-

EDITOR = gedit - The editor to use when selecting File > Edit to edit the G code from the AXIS menu. This must be configured for this menu item to work. Another valid entry is gnome-terminal -e vim. This entry does not apply to gmoccapy, as gmoccapy has an integrated editor.

-

TOOL_EDITOR = tooledit - The editor to use when editing the tool table (for example by selecting "File > Edit tool table…" in Axis). Other valid entries are "gedit", "gnome-terminal -e vim", and "gvim". This entry does not apply to gmoccapy, as gmoccapy has an integrated editor.

-

PYVCP = /filename.xml - The PyVCP panel description file. See the PyVCP Chapter for more information.

-

LATHE = 1 - This displays in lathe mode with a top view and with Radius and Diameter on the DRO.

-

GEOMETRY = XYZABCUVW - Controls the preview and backplot of rotary motion. This item consists of a sequence of axis letters, optionally preceded by a "-" sign. Only axes defined in [TRAJ]AXES should be used. This sequence specifies the order in which the effect of each axis is applied, with a "-" inverting the sense of the rotation. The proper GEOMETRY string depends on the machine configuration and the kinematics used to control it. The example string GEOMETRY=XYZBCUVW is for a 5-axis machine where kinematics causes UVW to move in the coordinate system of the tool and XYZ to move in the coordinate system of the material. The order of the letters is important, because it expresses the order in which the different transformations are applied. For example rotating around C then B is different than rotating around B then C. Geometry has no effect without a rotary axis.

-

ARCDIVISION = 64 - Set the quality of preview of arcs. Arcs are previewed by dividing them into a number of straight lines; a semicircle is divided into ARCDIVISION parts. Larger values give a more accurate preview, but take longer to load and result in a more sluggish display. Smaller values give a less accurate preview, but take less time to load and may result in a faster display. The default value of 64 means a circle of up to 3 inches will be displayed to within 1 mil (.03%).

-

MDI_HISTORY_FILE = - The name of a local MDI history file. If this is not specified Axis will save the MDI history in .axis_mdi_history in the user’s home directory. This is useful if you have multiple configurations on one computer.

-

USER_COMMAND_FILE = mycommands.py — The name of an optional, configuration-specific python file sourced by the axis gui instead of the user-specific file ~/.axisrc.

|

Note

|

The following [DISPLAY] item is used by the TKLinuxCNC interface only. |

-

HELP_FILE = tklinucnc.txt - Path to help file.

2.3. [FILTER] Section

AXIS and gmoccapy have the ability to send loaded files through a filter program. This filter can do any desired task: Something as simple as making sure the file ends with M2, or something as complicated as detecting whether the input is a depth image, and generating g-code to mill the shape it defines. The [FILTER] section of the ini file controls how filters work. First, for each type of file, write a PROGRAM_EXTENSION line. Then, specify the program to execute for each type of file. This program is given the name of the input file as its first argument, and must write RS274NGC code to standard output. This output is what will be displayed in the text area, previewed in the display area, and executed by LinuxCNC when Run.

-

PROGRAM_EXTENSION = .extension Description

If your post processor outputs files in all caps you might want to add the following line:

-

PROGRAM_EXTENSION = .NGC XYZ Post Processor

The following lines add support for the image-to-G code converter included with LinuxCNC.

-

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

-

png = image-to-gcode

-

gif = image-to-gcode

-

jpg = image-to-gcode

-

An example of a custom G code converter located in the linuxcnc directory.

-

'PROGRAM_EXTENSION = .gcode 3D Printer

-

gcode = /home/mill/linuxcnc/convert.py

-

|

Note

|

The program file assoiated with an extension must have either the full path to the program or be located in a directory that is on the system path. |

It is also possible to specify an interpreter:

-

PROGRAM_EXTENSION = .py Python Script

-

py = python

-

In this way, any Python script can be opened, and its output is treated as g-code. One such example script is available at nc_files/holecircle.py. This script creates g-code for drilling a series of holes along the circumference of a circle. Many more g-code generators are on the LinuxCNC Wiki site http://wiki.linuxcnc.org/.

If the environment variable AXIS_PROGRESS_BAR is set, then lines written to stderr of the form

-

FILTER_PROGRESS=%d

sets the AXIS progress bar to the given percentage. This feature should be used by any filter that runs for a long time.

Python filters should use the print function to output the result to Axis.

This example program filters a file and adds a W axis to match the Z axis. It depends on there being a space between each axis word to work.

#! /usr/bin/env python

import sys

def main(argv):

openfile = open(argv[0], 'r')

file_in = openfile.readlines()

openfile.close()

file_out = []

for line in file_in:

# print line

if line.find('Z') != -1:

words = line.rstrip('\n')

words = words.split(' ')

newword = ''

for i in words:

if i[0] == 'Z':

newword = 'W'+ i[1:]

if len(newword) > 0:

words.append(newword)

newline = ' '.join(words)

file_out.append(newline)

else:

file_out.append(line)

for item in file_out:

print "%s" % item

if __name__ == "__main__":

main(sys.argv[1:])

2.4. [RS274NGC] Section

-

PARAMETER_FILE = myfile.var - The file located in the same directory as the ini file which contains the parameters used by the interpreter (saved between runs).

-

ORIENT_OFFSET = 0 - A float value added to the R word parameter of an M19 Orient Spindle operation. Used to define an arbitrary zero position regardless of encoder mount orientation.

-

RS274NGC_STARTUP_CODE = G17 G20 G40 G49 G64 P0.001 G80 G90 G92 G94 G97 G98 - A string of NC codes that the interpreter is initialized with. This is not a substitute for specifying modal g-codes at the top of each ngc file, because the modal codes of machines differ, and may be changed by g-code interpreted earlier in the session.

-

SUBROUTINE_PATH = ncsubroutines:/tmp/testsubs:lathesubs:millsubs - Specifies a colon (:) separated list of up to 10 directories to be searched when single-file subroutines are specified in gcode. These directories are searched after searching [DISPLAY]PROGRAM_PREFIX (if it is specified) and before searching [WIZARD]WIZARD_ROOT (if specified). The paths are searched in the order that they are listed. The first matching subroutine file found in the search is used. Directories are specified relative to the current directory for the ini file or as absolute paths. The list must contain no intervening whitespace.

-

CENTER_ARC_RADIUS_TOLERANCE_INCH = n Default 0.00005

-

CENTER_ARC_RADIUS_TOLERANCE_MM = n Default 0.00127

-

USER_M_PATH = myfuncs:/tmp/mcodes:experimentalmcodes - Specifies a list of colon (:) separated directories for user defined functions. Directories are specified relative to the current directory for the ini file or as absolute paths. The list must contain no intervening whitespace.

A search is made for each possible user defined function, typically (M100-M199). The search order is:

-

[DISPLAY]PROGRAM_PREFIX (if specified)

-

If [DISPLAY]PROGRAM_PREFIX is not specified, search the default location: nc_files

-

Then search each directory in the list [RS274NGC]USER_M_PATH

The first executable M1xx found in the search is used for each M1xx.

-

|

Note

|

The maximum number of USER_M_PATH directories is defined at compile time (typ: USER_DEFINED_FUNCTION_MAX_DIRS == 5). |

|

Note

|

[WIZARD]WIZARD_ROOT is a valid search path but the Wizard has not been fully implemented and the results of using it are unpredictable. |

2.5. [EMCMOT] Section

This section is a custom section and is not used by LinuxCNC directly. Most configurations use values from this section to load the motion controller. For more information on the motion controller see the Motion Section.

-

EMCMOT = motmod - the motion controller name is typically used here.

-

BASE_PERIOD = 50000 - the Base task period in nanoseconds.

-

SERVO_PERIOD = 1000000 - This is the "Servo" task period in nanoseconds.

-

TRAJ_PERIOD = 100000 - This is the Trajectory Planner task period in nanoseconds.

-

COMM_TIMEOUT = 1.0 - Number of seconds to wait for Motion (the realtime part of the motion controller) to acknowledge receipt of messages from Task (the non-realtime part of the motion controller).

2.6. [TASK] Section

-

TASK = milltask - Specifies the name of the task executable. The task executable does various things, such as communicate with the UIs over NML, communicate with the realtime motion planner over non-HAL shared memory, and interpret gcode. Currently there is only one task executable that makes sense for 99.9% of users, milltask.

-

CYCLE_TIME = 0.010 - The period, in seconds, at which TASK will run. This parameter affects the polling interval when waiting for motion to complete, when executing a pause instruction, and when accepting a command from a user interface. There is usually no need to change this number.

2.7. [HAL] section

-

HALFILE = example.hal - Execute the file example.hal at start up. If HALFILE is specified multiple times, the files are executed in the order they appear in the ini file. Almost all configurations will have at least one HALFILE, and stepper systems typically have two such files, one which specifies the generic stepper configuration (core_stepper.hal) and one which specifies the machine pin out (xxx_pinout.hal). HALFILES are found using a search. If the named file is found in the directory containing the ini file, it is used. If the named file is not found in this ini file directory, a search is made using a system library of halfiles. A HALFILE may also be specified as an absolute path (when the name starts with a / character). Absolute paths are not recommended as their use may limit relocation of configurations.

-

HALFILE = texample.tcl [arg1 [arg2] …]] - Execute the tcl file texample.tcl at start up with arg1, arg2, etc as ::argv list. Files with a .tcl suffix are processed as above but use haltcl for processing See the HALTCL Chapter for more information.

-

HALFILE = LIB:sys_example.hal - Execute the system library file sys_example.hal at start up. Explicit use of the LIB: prefix causes use of the system library HALFILE without searching the ini file directory.

-

HALFILE = LIB:sys_texample.tcl [arg1 [arg2 …]] - Execute the system library file sys_texample.tcl at start up. Explicit use of the LIB: prefix causes use of the system library HALFILE without searching the ini file directory.

HALFILE items specify files that loadrt Hal components and make signal connections between component pins. Common mistakes are 1) omission of the addf statement needed to add a component’s function(s) to a thread, 2) incomplete signal (net) specifiers. Omission of required addf statements is almost always an error. Signals usually include one or more input connections and a single output (but both are not strictly required). A system library file is provided to make checks for these conditions and report to stdout and in a popup gui:

HALFILE = LIB:halcheck.tcl [ nopopup ]

|

Note

|

The LIB:halcheck.tcl line should be the last [HAL]HALFILE. Specify the nopopup option to suppress the popup message and allow immediate starting. Connections made using a POSTGUI_HALFILE are not checked. |

-

TWOPASS = ON - Use twopass processing for loading HAL components. With TWOPASS processing, [HAL]HALFILE= lines are processed in two passes. In the first pass (pass0), all HALFILES are read and multiple appearances of loadrt and loadusr commands are accumulated. These accumulated load commands are executed at the end of pass0. This accumulation allows load lines to be specified more than once for a given component (provided the names= names used are unique on each use). In the second pass (pass1), the HALFILES are reread and all commands except the previously executed load commands are executed.

-

TWOPASS = nodelete verbose - The TWOPASS feature can be activated with any non-null string including the keywords verbose and nodelete. The verbose keyword causes printing of details to stdout. The nodelete keyword preserves temporary files in /tmp.

For more information see the Hal TWOPASS chapter.

-

HALCMD = command - Execute command as a single HAL command. If HALCMD is specified multiple times, the commands are executed in the order they appear in the ini file. HALCMD lines are executed after all HALFILE lines.

-

SHUTDOWN = shutdown.hal - Execute the file shutdown.hal when LinuxCNC is exiting. Depending on the hardware drivers used, this may make it possible to set outputs to defined values when LinuxCNC is exited normally. However, because there is no guarantee this file will be executed (for instance, in the case of a computer crash) it is not a replacement for a proper physical e-stop chain or other protections against software failure.

-

POSTGUI_HALFILE = example2.hal - Execute example2.hal after the GUI has created its HAL pins. Some GUIs create hal pins and support the use of a postgui halfile to use them. GUIs that support postgui halfiles include Touchy, Axis, Gscreen, and gmoccapy.

See section <<sec:pyvcp-with-axis,pyVCP with Axis>> Section for more information.

-

HALUI = halui - adds the HAL user interface pins. For more information see the HAL User Interface chapter.

2.8. [HALUI] section

-

MDI_COMMAND = G53 G0 X0 Y0 Z0 - An MDI command can be executed by using halui.mdi-command-00. Increment the number for each command listed in the [HALUI] section.

2.9. [APPLICATIONS] Section

LinuxCNC can start other applications before the specified gui is started. The applications can be started after a specified delay to allow for gui-dependent actions (like creating gui-specific hal pins).

-

DELAY = value - seconds to wait beore starting other applications. A delay may be needed if an application has dependencies on [HAL]POSTGUI_HALFILE actions or gui-created hal pins (default DELAY=0).

-

APP = appname [arg1 [arg2 …]] - Application to be started. This specification can be included multiple times. The appname can be explicitly named as an absolute or tilde specified filename (first character is / or ~), a relative filename (first characters of filename are ./), or as a file in the inifile directory. If no executable file is found using these names, then the user search PATH is used to find the application.

Examples:

-

Simulate inputs to hal pins for testing (using sim_pin — a simple gui to set inputs to parameters, unconnected pins, or signals with no writers):

APP = sim_pin motion.probe-input halui.abort motion.analog-in-00

-

Invoke halshow with a previuosly saved watchlist. Since linuxcnc sets the working directory to the directory for the inifile, you can refer to files in that directory (example: my.halshow):

APP = halshow my.halshow

-

Alternatively, a watchlist file identified with a full pathname could be specified:

APP = halshow ~/saved_shows/spindle.halshow

-

Open halscope using a previously saved configuration:

APP = halscope -i my.halscope

-

2.10. [TRAJ] Section

|

Warning

|

The new Trajectory Planner (TP) is on by default. If you have no TP settings in your [TRAJ] section - LinuxCNC defaults to: ARC_BLEND_ENABLE = 1 ARC_BLEND_FALLBACK_ENABLE = 0 ARC_BLEND_OPTIMIZATION_DEPTH = 50 ARC_BLEND_GAP_CYCLES = 4 ARC_BLEND_RAMP_FREQ = 100 |

The [TRAJ] section contains general parameters for the trajectory planning module in motion.

-

ARC_BLEND_ENABLE = 1 - Turn on new TP. If set to 0 TP uses parabolic blending (1 segment look ahead.) Default value 1.

-

ARC_BLEND_FALLBACK_ENABLE = 0 - Optionally fall back to parabolic blends if the estimated speed is faster. However, this estimate is rough, and it seems that just disabling it gives better performance. Default value 0.

-

ARC_BLEND_OPTIMIZATION_DEPTH = 50 - Look ahead depth in number of segments.

To expand on this a bit, you can choose this value somewhat arbitrarily. Here’s a formula to estimate how much depth you need for a particular config:

# n = v_max / (2.0 * a_max * t_c) # where: # n = optimization depth # v_max = max axis velocity (UU / sec) # a_max = max axis acceleration (UU / sec) # t_c = servo period (seconds)

So, a machine with a maximum axis velocity of 10 IPS, a max acceleration of 100 IPS^2, and a servo period of 0.001 sec would need:

10 / (2.0 * 100 * 0.001) = 50 segments to always reach maximum velocity along the fastest axis.

In practice, this number isn’t that important to tune, since the look ahead rarely needs the full depth unless you have lots of very short segments. If during testing, you notice strange slowdowns and can’t figure out where they come from, first try increasing this depth using the formula above.

If you still see strange slowdowns, it may be because you have short segments in the program. If this is the case, try adding a small tolerance for Naive CAM detection. A good rule of thumb is this:

# min_length ~= v_req * t_c # where: # v_req = desired velocity in UU / sec # t_c = servo period (seconds)

If you want to travel along a path at 1 IPS = 60 IPM, and your servo period is 0.001 sec, then any segments shorter than min_length will slow the path down. If you set Naive CAM tolerance to around this min length, overly short segments will be combined together to eliminate this bottleneck. Of course, setting the tolerance too high means big path deviations, so you have to play with it a bit to find a good value. I’d start at 1/2 of the min_length, then work up as needed.

-

ARC_BLEND_GAP_CYCLES = 4 How short the previous segment must be before the trajectory planner consumes it.

Often, a circular arc blend will leave short line segments in between the blends. Since the geometry has to be circular, we can’t blend over all of a line if the next one is a little shorter. Since the trajectory planner has to touch each segment at least once, it means that very tiny segments will slow things down significantly. My fix to this way to "consume" the short segment by making it a part of the blend arc. Since the line+blend is one segment, we don’t have to slow down to hit the very short segment. Likely, you won’t need to touch this setting.

-

ARC_BLEND_RAMP_FREQ = 20 - This is a cutoff frequency for using ramped velocity.

Ramped velocity in this case just means constant acceleration over the whole segment. This is less optimal than a trapezoidal velocity profile, since the acceleration is not maximized. However, if the segment is short enough, there isn’t enough time to accelerate much before we hit the next segment. Recall the short line segments from the previous example. Since they’re lines, there’s no cornering acceleration, so we’re free to accelerate up to the requested speed. However, if this line is between two arcs, then it will have to quickly decelerate again to be within the maximum speed of the next segment. This means that we have a spike of acceleration, then a spike of deceleration, causing a large jerk, for very little performance gain. This setting is a way to eliminate this jerk for short segments.

Basically, if a segment will complete in less time than 1 / ARC_BLEND_RAMP_FREQ, we don’t bother with a trapezoidal velocity profile on that segment, and use constant acceleration. (Setting ARC_BLEND_RAMP_FREQ = 1000 is equivalent to always using trapezoidal acceleration, if the servo loop is 1kHz).

You can characterize the worst-case loss of performance by comparing the velocity that a trapezoidal profile reaches vs. the ramp:

# v_ripple = a_max / (4.0 * f) # where: # v_ripple = average velocity "loss" due to ramping # a_max = max axis acceleration # f = cutoff frequency from INI

For the aforementioned machine, the ripple for a 20Hz cutoff frequency is 100 / (4 * 20) = 1.25 IPS. This seems high, but keep in mind that it is only a worst-case estimate. In reality , the trapezoidal motion profile is limited by other factors, such as normal acceleration or requested velocity, and so the actual performance loss should be much smaller. Increasing the cutoff frequency can squeeze out more performance, but make the motion rougher due to acceleration discontinuities. A value in the range 20Hz to 200Hz should be reasonable to start.

Finally, no amount of tweaking will speed up a toolpath with lots of small, tight corners, since you’re limited by cornering acceleration.

-

COORDINATES = X Y Z - The names of the axes being controlled. Only X, Y, Z, A, B, C, U, V, W are valid. Only axes named in COORDINATES are accepted in g-code. This has no effect on the mapping from G-code axis names (X- Y- Z-) to joint numbers—for trivial kinematics, X is always joint 0, A is always joint 3, and U is always joint 6, and so on. It is permitted to write an axis name twice (e.g., X Y Y Z for a gantry machine) but this has no effect.

-

AXES = 3 - One more than the number of the highest joint number in the system. For an XYZ machine, the joints are numbered 0, 1 and 2; in this case AXES should be 3. For an XYUV machine using trivial kinematics, the V joint is numbered 7 and therefore AXES should be 8. For a machine with nontrivial kinematics (e.g., scarakins) this will generally be the number of controlled joints.

-

JOINTS = 3 - (This config variable is used by the Axis and gmoccapy (from release 2.0) GUI only, not by the trajectory planner in the motion controller.) Specifies the number of joints (motors) in the system. For example, an XYZ machine with a single motor for each axis has 3 joints. A gantry machine with one motor on each of two of the axes, and two motors on the third axis, has 4 joints.

-

HOME = 0 0 0 - Coordinates of the homed position of each axis. Again for a fourth axis you will need 0 0 0 0. This value is only used for machines with nontrivial kinematics. On machines with trivial kinematics (mill, lathe, gantry types) this value is ignored.

-

LINEAR_UNITS = <units> - Specifies the machine units for linear axes. Possible choices are mm or inch. This does not affect the linear units in NC code (the G20 and G21 words do this).

-

ANGULAR_UNITS = <units> - Specifies the machine units for rotational axes. Possible choices are deg, degree (360 per circle), rad, radian (2pi per circle), grad, or gon (400 per circle). This does not affect the angular units of NC code. In RS274NGC, A-, B- and C- words are always expressed in degrees.

-

DEFAULT_VELOCITY = 0.0167 - The initial rate for jogs of linear axes, in machine units per second. The value shown in Axis equals machine units per minute.

-

DEFAULT_ACCELERATION = 2.0 - In machines with nontrivial kinematics, the acceleration used for "teleop" (Cartesian space) jogs, in machine units per second per second.

-

MAX_VELOCITY = 5.0 - The maximum velocity for any axis or coordinated move, in machine units per second. The value shown equals 300 units per minute.

-

MAX_ACCELERATION = 20.0 - The maximum acceleration for any axis or coordinated axis move, in machine units per second per second.

-

POSITION_FILE = position.txt - If set to a non-empty value, the joint positions are stored between runs in this file. This allows the machine to start with the same coordinates it had on shutdown. This assumes there was no movement of the machine while powered off. If unset, joint positions are not stored and will begin at 0 each time LinuxCNC is started. This can help on smaller machines without home switches.

-

NO_FORCE_HOMING = 1 - The default behavior is for LinuxCNC to force the user to home the machine before any MDI command or a program is run. Normally, only jogging is allowed before homing. Setting NO_FORCE_HOMING = 1 allows the user to make MDI moves and run programs without homing the machine first. Interfaces without homing ability will need to have this option set to 1.

|

Warning

|

LinuxCNC will not know your axis travel limits when using NO_FORCE_HOMING = 1. |

2.11. [AXIS_<num>] Section

The [AXIS_0], [AXIS_1], etc. sections contains general parameters for the individual components in the axis control module. The axis section names begin numbering at 0, and run through the number of axes specified in the [TRAJ] AXES entry minus 1.

Typically (but not always):

-

AXIS_0 = X

-

AXIS_1 = Y

-

AXIS_2 = Z

-

AXIS_3 = A

-

AXIS_4 = B

-

AXIS_5 = C

-

AXIS_6 = U

-

AXIS_7 = V

-

AXIS_8 = W

-

TYPE = LINEAR - The type of axes, either LINEAR or ANGULAR.

-

WRAPPED_ROTARY = 1 - When this is set to 1 for an ANGULAR axis the axis will move 0-359.999 degrees. Positive Numbers will move the axis in a positive direction and negative numbers will move the axis in the negative direction.

-

LOCKING_INDEXER = 1 - When this is set to 1, a G0 move for this axis will initiate an unlock with axis.N.unlock pin then wait for the axis.N.is-unlocked pin then move the axis at the rapid rate for that axis. After the move, the axis.N.unlock will be false and motion will wait for axis.N.is-unlocked to go false. Moving with other axes is not allowed when moving a locked rotary axis. If motion is disabled (estop for instance), while the axis.N.unlock pin is set, the axis.N.unlock pin is reset to false.

-

UNITS = INCH - If specified, this setting overrides the related [TRAJ] UNITS setting. (e.g., [TRAJ]LINEAR_UNITS if the TYPE of this axis is LINEAR, [TRAJ]ANGULAR_UNITS if the TYPE of this axis is ANGULAR)

-

MAX_VELOCITY = 1.2 - Maximum velocity for this axis in machine units per second.

-

MAX_ACCELERATION = 20.0 - Maximum acceleration for this axis in machine units per second squared.

-

BACKLASH = 0.0000 - Backlash is in machine units. Backlash compensation can be used to make up for small deficiencies in the hardware used to drive an axis. If backlash is added to an axis and you are using steppers the STEPGEN_MAXACCEL must be increased to 1.5 to 2 times the MAX_ACCELERATION for the axis. Excessive backlash compensation can cause an axis to jerk as it changes direction. If a COMP_FILE is specificed for an axis BACKLASH is not used.

-

COMP_FILE = file.extension - The compensation file consists of map of position information for the axis. Compensation file values are in machine units. Each set of values are are on one line separated by a space. The first value is the nominal value (the commanded position). The second and third values depend on the setting of COMP_FILE_TYPE. Points in between nominal values are interpolated between the two nominals. Compensation files must start with the smallest nominal and be in ascending order to the largest value of nominals. File names are case sensitive and can contain letters and/or numbers. Currently the limit inside LinuxCNC is for 256 triplets per axis.

If COMP_FILE is specified for an axis, BACKLASH is not used. A COMP_FILE_TYPE must be specified for each COMP_FILE. -

COMP_FILE_TYPE = 0 or 1 - Specifies the type of compensation file. The first value is the nominal (commanded) position for both types.

-

Type 0: The second value specifies the actual position as the axis is moving in the positive direction (increasing value) and the third value specifies the actual position as the axis is moving in the negative direction (decreasing value).

Type 0 Example-1.000 -1.005 -0.995 0.000 0.002 -0.003 1.000 1.003 0.998

-

Type 1: The second value specifies positive offset from nominal while traveling in the positive direction. The third value specifies the negitive offset from nominal while traveling in a negitive direction.

Type 1 Example-1.000 0.005 -0.005 0.000 0.002 -0.003 1.000 0.003 -0.004

-

-

MIN_LIMIT = -1000 - The minimum limit for axis motion, in machine units. When this limit is reached, the controller aborts axis motion. The axis must be homed before MIN_LIMIT is in force. For a rotary axis with unlimited rotation having no MIN_LIMIT for that axis in the [AXIS_n] section then the value -1e99 is used.

-

MAX_LIMIT = 1000 - The maximum limit for axis motion, in machine units. When this limit is reached, the controller aborts axis motion. The axis must be homed before MAX_LIMIT is in force. For a rotary axis with unlimited rotation having no MAX_LIMIT for that axis in the [AXIS_n] section then the value 1e99 is used.

-

MIN_FERROR = 0.010 - This is the value in machine units by which the axis is permitted to deviate from commanded position at very low speeds. If MIN_FERROR is smaller than FERROR, the two produce a ramp of error trip points. You could think of this as a graph where one dimension is speed and the other is permitted following error. As speed increases the amount of following error also increases toward the FERROR value.

-

FERROR = 1.0 - FERROR is the maximum allowable following error, in machine units. If the difference between commanded and sensed position exceeds this amount, the controller disables servo calculations, sets all the outputs to 0.0, and disables the amplifiers. If MIN_FERROR is present in the .ini file, velocity-proportional following errors are used. Here, the maximum allowable following error is proportional to the speed, with FERROR applying to the rapid rate set by [TRAJ]MAX_VELOCITY, and proportionally smaller following errors for slower speeds. The maximum allowable following error will always be greater than MIN_FERROR. This prevents small following errors for stationary axes from inadvertently aborting motion. Small following errors will always be present due to vibration, etc.

These parameters are Homing related, for a better explanation read the Homing Configuration Chapter.

-

HOME = 0.0 - The position that the joint will go to upon completion of the homing sequence.

-

HOME_OFFSET = 0.0 - The axis position of the home switch or index pulse, in machine units. When the home point is found during the homing process, this is the position that is assigned to that point. When sharing home and limit switches and using a home sequence that will leave the home/limit switch in the toggled state the home offset can be used define the home switch position to be other than 0 if your HOME position is desired to be 0.

-

HOME_SEARCH_VEL = 0.0 - Initial homing velocity in machine units per second. Sign denotes direction of travel. A value of zero means assume that the current location is the home position for the machine. If your machine has no home switches you will want to leave this value at zero.

-

HOME_LATCH_VEL = 0.0 - Homing velocity in machine units per second to the home switch latch position. Sign denotes direction of travel.

-

HOME_FINAL_VEL = 0.0 - Velocity in machine units per second from home latch position to home position. If left at 0 or not included in the axis rapid velocity is used. Must be a positive number.

-

HOME_USE_INDEX = NO - If the encoder used for this axis has an index pulse, and the motion card has provision for this signal you may set it to yes. When it is yes, it will affect the kind of home pattern used. Currently, you can’t home to index with steppers unless you’re using stepgen in velocity mode and PID.

-

HOME_IGNORE_LIMITS = NO - When you use the limit switch as a home switch and the limit switch this should be set to YES. When set to YES the limit switch for this axis is ignored when homing. You must configure your homing so that at the end of your home move the home/limit switch is not in the toggled state you will get a limit switch error after the home move.

-

HOME_IS_SHARED = <n> - If the home input is shared by more than one axis set <n> to 1 to prevent homing from starting if the one of the shared switches is already closed. Set <n> to 0 to permit homing if a switch is closed.

-

HOME_SEQUENCE = <n> - Used to define the "Home All" sequence. <n> starts at 0 and no numbers may be skipped. If left out or set to -1 the joint will not be homed by the "Home All" function. More than one axis can be homed at the same time.

-

VOLATILE_HOME = 0 - When enabled (set to 1) this joint will be unhomed if the Machine Power is off or if E-Stop is on. This is useful if your machine has home switches and does not have position feedback such as a step and direction driven machine.

These parameters are relevant to axes controlled by servos.

|

Warning

|

The following are custom INI file entries that you may find in a sample INI file or a wizard generated file. These are not used by the LinuxCNC software. They are only there to put all the settings in one place. For more information on custom INI file entries see the Custom Sections and Variables subsection. |

The following items might be used by a PID component and the assumption is that the output is volts.

-

DEADBAND = 0.000015 - How close is close enough to consider the motor in position, in machine units. This is often set to a distance equivalent to 1, 1.5, 2, or 3 encoder counts, but there are no strict rules. Looser (larger) settings allow less servo hunting at the expense of lower accuracy. Tighter (smaller) settings attempt higher accuracy at the expense of more servo hunting. Is it really more accurate if it’s also more uncertain? As a general rule, it’s good to avoid, or at least limit, servo hunting if you can.

Be careful about going below 1 encoder count, since you may create a condition where there is no place that your servo is happy. This can go beyond hunting (slow) to nervous (rapid), and even to squealing which is easy to confuse with oscillation caused by improper tuning. Better to be a count or two loose here at first, until you’ve been through gross tuning at least.

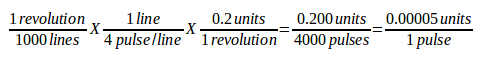

Example of calculating machine units per encoder pulse to use in deciding DEADBAND value:

-

BIAS = 0.000 - This is used by hm2-servo and some others. Bias is a constant amount that is added to the output. In most cases it should be left at zero. However, it can sometimes be useful to compensate for offsets in servo amplifiers, or to balance the weight of an object that moves vertically. bias is turned off when the PID loop is disabled, just like all other components of the output.

-

P = 50 - The proportional gain for the axis servo. This value multiplies the error between commanded and actual position in machine units, resulting in a contribution to the computed voltage for the motor amplifier. The units on the P gain are volts per machine unit, e.g.,

-

I = 0 - The integral gain for the axis servo. The value multiplies the cumulative error between commanded and actual position in machine units, resulting in a contribution to the computed voltage for the motor amplifier. The units on the I gain are volts per machine unit second, e.g.,

-

D = 0 - The derivative gain for the axis servo. The value multiplies the difference between the current and previous errors, resulting in a contribution to the computed voltage for the motor amplifier. The units on the D gain are volts per machine unit per second, e.g.,

-

FF0 = 0 - The 0th order feed forward gain. This number is multiplied by the commanded position, resulting in a contribution to the computed voltage for the motor amplifier. The units on the FF0 gain are volts per machine unit, e.g.,

-

FF1 = 0 - The 1st order feed forward gain. This number is multiplied by the change in commanded position per second, resulting in a contribution to the computed voltage for the motor amplifier. The units on the FF1 gain are volts per machine unit per second, e.g.,

-

FF2 = 0 - The 2nd order feed forward gain. This number is multiplied by the change in commanded position per second per second, resulting in a contribution to the computed voltage for the motor amplifier. The units on the FF2 gain are volts per machine unit per second per second, e.g.,

-

OUTPUT_SCALE = 1.000 -

-

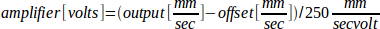

OUTPUT_OFFSET = 0.000 - These two values are the scale and offset factors for the axis output to the motor amplifiers. The second value (offset) is subtracted from the computed output (in volts), and divided by the first value (scale factor), before being written to the D/A converters. The units on the scale value are in true volts per DAC output volts. The units on the offset value are in volts. These can be used to linearize a DAC. Specifically, when writing outputs, the LinuxCNC first converts the desired output in quasi-SI units to raw actuator values, e.g., volts for an amplifier DAC. This scaling looks like:

The value for scale can be obtained analytically by doing a unit analysis, i.e., units are [output SI units]/[actuator units]. For example, on a machine with a velocity mode amplifier such that 1 volt results in 250 mm/sec velocity.

Note that the units of the offset are in machine units, e.g., mm/sec, and they are pre-subtracted from the sensor readings. The value for this offset is obtained by finding the value of your output which yields 0.0 for the actuator output. If the DAC is linearized, this offset is normally 0.0.

The scale and offset can be used to linearize the DAC as well, resulting in values that reflect the combined effects of amplifier gain, DAC non-linearity, DAC units, etc.

To do this, follow this procedure.

-

Build a calibration table for the output, driving the DAC with a desired voltage and measuring the result.

-

Do a least-squares linear fit to get coefficients a, b such that

-

Note that we want raw output such that our measured result is identical to the commanded output. This means

-

-

As a result, the a and b coefficients from the linear fit can be used as the scale and offset for the controller directly.

See the following table for an example of voltage measurements.

| Raw | Measured |

|---|---|

-10 |

-9.93 |

-9 |

-8.83 |

0 |

-0.03 |

1 |

0.96 |

9 |

9.87 |

10 |

10.87 |

-

MAX_OUTPUT = 10 - The maximum value for the output of the PID compensation that is written to the motor amplifier, in volts. The computed output value is clamped to this limit. The limit is applied before scaling to raw output units. The value is applied symmetrically to both the plus and the minus side.

-

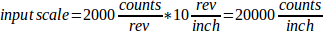

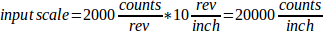

INPUT_SCALE = 20000 - in Sample configs

-

ENCODER_SCALE = 20000 - in PNCconf built configs Specifies the number of pulses that corresponds to a move of one machine unit as set in the [TRAJ] section. For a linear axis one machine unit will be equal to the setting of LINEAR_UNITS. For an angular axis one unit is equal to the setting in ANGULAR_UNITS. A second number, if specified, is ignored. For example, on a 2000 counts per rev encoder, and 10 revs/inch gearing, and desired units of inch, we have:

These parameters are relevant to axes controlled by steppers.

|

Warning

|

The following are custom INI file entries that you may find in a sample INI file or a wizard generated file. These are not used by the LinuxCNC software. They are only there to put all the settings in one place. For more information on custom INI file entries see the Custom Sections and Variables subsection. |

The following items might be used by a stepgen component.

-

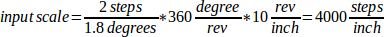

SCALE = 4000 - in Sample configs

-

STEP_SCALE = 4000 - in PNCconf built configs Specifies the number of pulses that corresponds to a move of one machine unit as set in the [TRAJ] section. For stepper systems, this is the number of step pulses issued per machine unit. For a linear axis one machine unit will be equal to the setting of LINEAR_UNITS. For an angular axis one unit is equal to the setting in ANGULAR_UNITS. For servo systems, this is the number of feedback pulses per machine unit. A second number, if specified, is ignored.

For example, on a 1.8 degree stepper motor with half-stepping, and 10 revs/inch gearing, and desired machine units of inch, we have:

-

ENCODER_SCALE = 20000 (Optionally used in PNCconf built configs) - Specifies the number of pulses that corresponds to a move of one machine unit as set in the [TRAJ] section. For a linear axis one machine unit will be equal to the setting of LINEAR_UNITS. For an angular axis one unit is equal to the setting in ANGULAR_UNITS. A second number, if specified, is ignored. For example, on a 2000 counts per rev encoder, and 10 revs/inch gearing, and desired units of inch, we have:

-

STEPGEN_MAXACCEL = 21.0 - Acceleration limit for the step generator. This should be 1% to 10% larger than the axis MAX_ACCELERATION. This value improves the tuning of stepgen’s "position loop". If you have added backlash compensation to an axis then this should be 1.5 to 2 times greater than MAX_ACCELERATION.

-

STEPGEN_MAXVEL = 1.4 - Older configuration files have a velocity limit for the step generator as well. If specified, it should also be 1% to 10% larger than the axis MAX_VELOCITY. Subsequent testing has shown that use of STEPGEN_MAXVEL does not improve the tuning of stepgen’s position loop.

2.12. [EMCIO] Section

-

EMCIO = io - Name of IO controller program

-

CYCLE_TIME = 0.100 - The period, in seconds, at which EMCIO will run. Making it 0.0 or a negative number will tell EMCIO not to sleep at all. There is usually no need to change this number.

-

TOOL_TABLE = tool.tbl - The file which contains tool information, described in the User Manual.

-

TOOL_CHANGE_POSITION = 0 0 2 - Specifies the XYZ location to move to when performing a tool change if three digits are used. Specifies the XYZABC location when 6 digits are used. Specifies the XYZABCUVW location when 9 digits are used. Tool Changes can be combined. For example if you combine the quill up with change position you can move the Z first then the X and Y.

-

TOOL_CHANGE_WITH_SPINDLE_ON = 1 - The spindle will be left on during the tool change when the value is 1. Useful for lathes or machines where the material is in the spindle, not the tool.

-

TOOL_CHANGE_QUILL_UP = 1 - The Z axis will be moved to machine zero prior to the tool change when the value is 1. This is the same as issuing a G0 G53 Z0.

-

TOOL_CHANGE_AT_G30 = 1 - The machine is moved to reference point defined by parameters 5181-5186 for G30 if the value is 1. For more information see the Parameters Section and the <<gcode:g30-g30.1.

-

RANDOM_TOOLCHANGER = 1 - This is for machines that cannot place the tool back into the pocket it came from. For example, machines that exchange the tool in the active pocket with the tool in the spindle.