1. Audiencia Objetivo

Este documento es una colección de notas sobre los aspectos internos de LinuxCNC. Principalmente de interés para los desarrolladores. Sin embargo, gran parte de la información también puede ser de interés para integradores de sistemas u otros que estén simplemente interesados sobre cómo funciona LinuxCNC. Mucha de esta información está ahora desactualizada y nunca ha sido revisada su exactitud.

2. Organización

Habrá un capítulo para cada uno de los componentes principales de LinuxCNC, así como capítulos que cubren cómo esos componentes trabajan juntos. Este documento es por mucho un trabajo en progreso y su diseño puede cambiar en el futuro.

3. Términos y definiciones

-

EJE: un eje es uno de los nueve grados de libertad que define la posición de una herramienta en el espacio cartesiano tridimensional. Los nueve ejes son referidos como X, Y, Z, A, B, C, U, V y W. Las coordenadas lineales ortogonales X, Y y Z determinan dónde está posicionada la punta de la herramienta. Las coordenadas angulares A, B y C determinan la orientación de la herramienta. Un segundo conjunto de coordenadas lineales ortogonales U, V y W permite el movimiento de la herramienta (generalmente para acciones de corte) en relación con los ejes previamente desplazados y rotados. Lamentablemente, "eje" se usa a veces para significar un grado de libertad de la máquina en sí, como los carros longitudinal y transversal o el avance fino del husillo de una fresadora vertical. En estas maquinas, esto no causa confusión ya que, por ejemplo, el movimiento de la mesa corresponde directamente al movimiento a lo largo del eje X. Sin embargo, las articulaciones de hombro y codo de un brazo robótico y los actuadores lineales de un hexápodo no se corresponde al movimiento a lo largo de ningún eje cartesiano y en general es importante hacer la distinción entre el eje cartesiano y grados de libertad de la máquina. En este documento, esto último se llamarán articulaciones, no ejes. (Las GUI y algunas otras partes de el código no siempre sigue esta distinción, pero las partes internas de el controlador de movimiento si lo hacen.)

-

ARTICULACIÓN: una articulación es cada una de las partes móviles de la máquina. Las articulaciones son distintas de los ejes, aunque los dos términos a veces se usan (incorrectamente) para significa lo mismo. En LinuxCNC, una articulación es un objeto físico que puede ser movido, no una coordenada en el espacio. Por ejemplo, todos los carros, la palanca del husillo o un plato giratorio de una fresadora vertical son articulaciones. El hombro, el codo y la muñeca de un brazo robótico son articulaciones, al igual que los actuadores lineales de un hexápodo. Cada articulación tiene un motor o actuador de algún tipo asociado con ella. Las articulaciones no corresponden necesariamente a los ejes X, Y y Z, aunque para máquinas con cinemática trivial, puede ser el caso. Incluso en esas máquinas, la posición articular y la posición del eje son cosas inherentemente diferentes. En este documento, los términos articulación y eje se utilizan con cuidado para respetar sus distintos significados. Desafortunadamente, eso no es necesariamente cierto en ningún otro lado. En en particular, las GUI para máquinas con cinemática trivial pueden pasar por alto o oculta completamente la distinción entre articulaciones y ejes. Adicionalmente, el archivo INI usa el término eje para datos que serían más precisos describirse como datos de articulaciones, como las escalas de entrada y salida, etc.

|

Nota

|

En la versión 2.8 de LinuxCNC ya se hace esta distinción. El archivo INI cuenta con la nueva sección [JOINT_<núm>]. Muchos de los parámetros que antes eran propios de la sección [AXIS_<letra>] ahora están en la nueva sección. Otras secciones, como [KINS] también adquieren nuevos parámetros para ajustarse a esto. Se ha provisto una secuencia de comandos para transformar archivos INI antiguos a la nueva configuración ejes/articulaciones. |

-

POSE- una pose es una posición completamente especificada en un espacio cartesiano 3-D. En el controlador de movimiento LinuxCNC, cuando nos referimos a una pose nos referimos a una estructura EmcPose, que contiene seis coordenadas lineales (X, Y, Z, U, V y W) y tres angulares (A, B y C).

-

coord, o modo coordinado, significa que todas las articulaciones están sincronizadas y se mueven juntas según lo ordenado por el código de nivel superior. Es el modo normal al mecanizar. En el modo coordinado, se supone que los comandos se dan en el marco de referencia cartesiano, y si la máquina no es cartesiana, los comandos son traducidos por la cinemática para impulsar cada articulación en el espacio articular según sea necesario.

-

free, o modo libre, significa que los comandos se interpretan en el espacio articular. Se usa para mover manualmente (jog) articulaciones individuales, aunque no impide que se muevan múltiples articulaciones a la vez (creo). La detección del punto de inicio de los ejes (homing) también se realiza en modo libre; de hecho, a las máquinas con cinemática no trivial deben tener detectados sus puntos de inicio antes de que puedan pasar al modo coord o teleop.

-

teleop es el modo que probablemente se necesite si se hace trote con un hexápodo. Los comandos de trote implementados por el controlador de movimiento son trotes articulares, que funcionan en modo free. Pero si se desea mover un hexápodo o una máquina similar a lo largo de un eje cartesiano en particular, se debe operar más de una articulación. Para eso está teleop.

4. Descripción general de la arquitectura

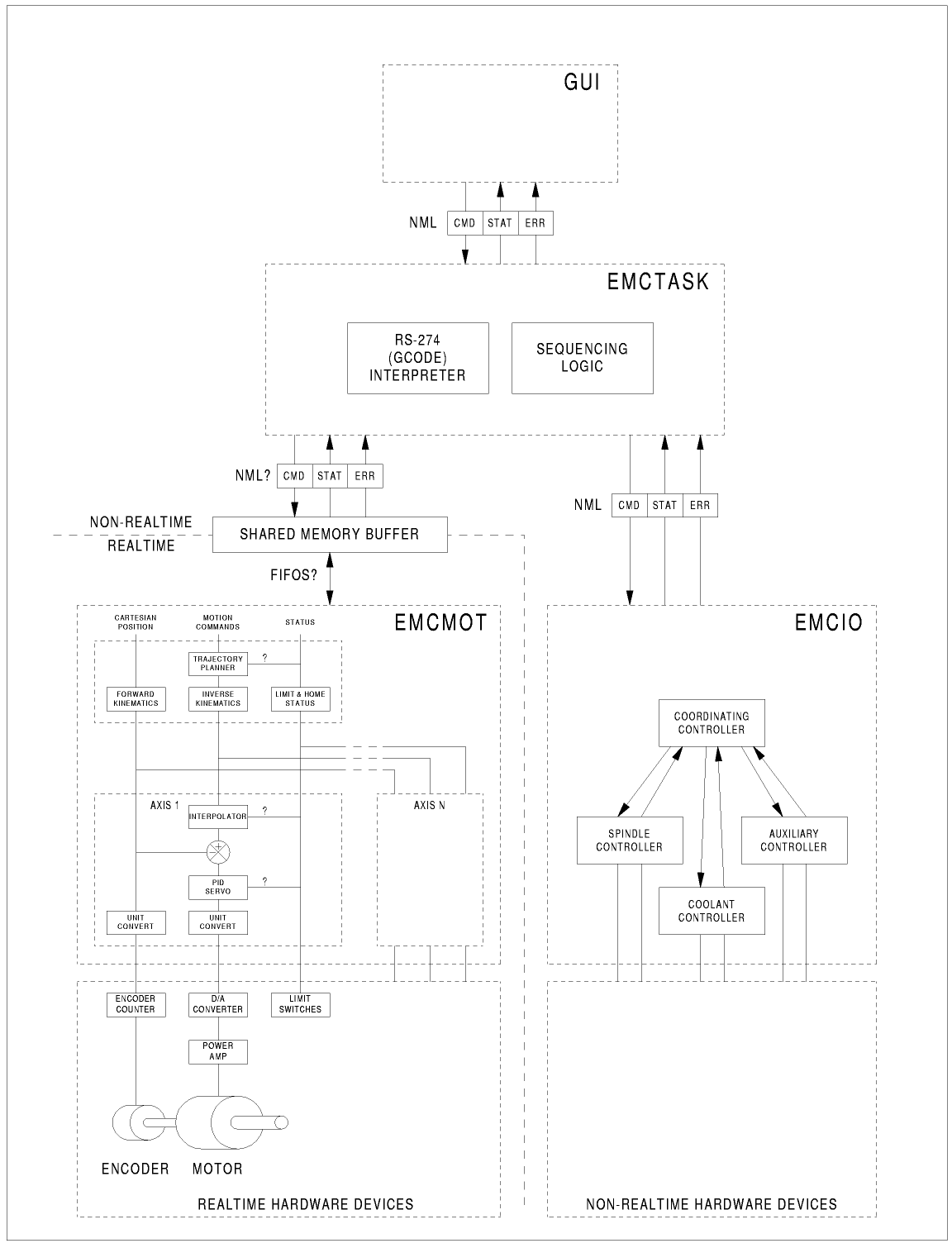

Hay cuatro componentes contenidos en la Arquitectura LinuxCNC: un controlador de movimiento (EMCMOT), un controlador de E/S discreto (EMCIO), un ejecutor de tareas que los coordina (EMCTASK) y varios interfaces de usuario en modos texto y gráficos. Cada uno de ellos se describirá en el presente documento, tanto desde el punto de vista del diseño como del punto de vista de los desarrolladores (dónde encontrar los datos necesarios, cómo ampliar/modificar cosas fácilmente, etc.).

4.1. Arquitectura del software LinuxCNC

Al nivel más general, LinuxCNC es un jerarquía de tres controladores: el manejador de comandos a nivel de tarea e intérprete de programa, el controlador de movimiento y el controlador de E/S discretas. El controlador de E/S discretas está implementado como una jerarquía de controladores, en este caso para husillo, refrigerante y subsistemas auxiliares (p. ej., Estop). El controlador de tareas coordina las acciones de los controladores de movimiento y de E/S discretas. Sus acciones están programadas en programas convencionales de control numérico "código G y M", que son interpretados por el controlador de tareas en mensajes NML y enviados al movimiento.

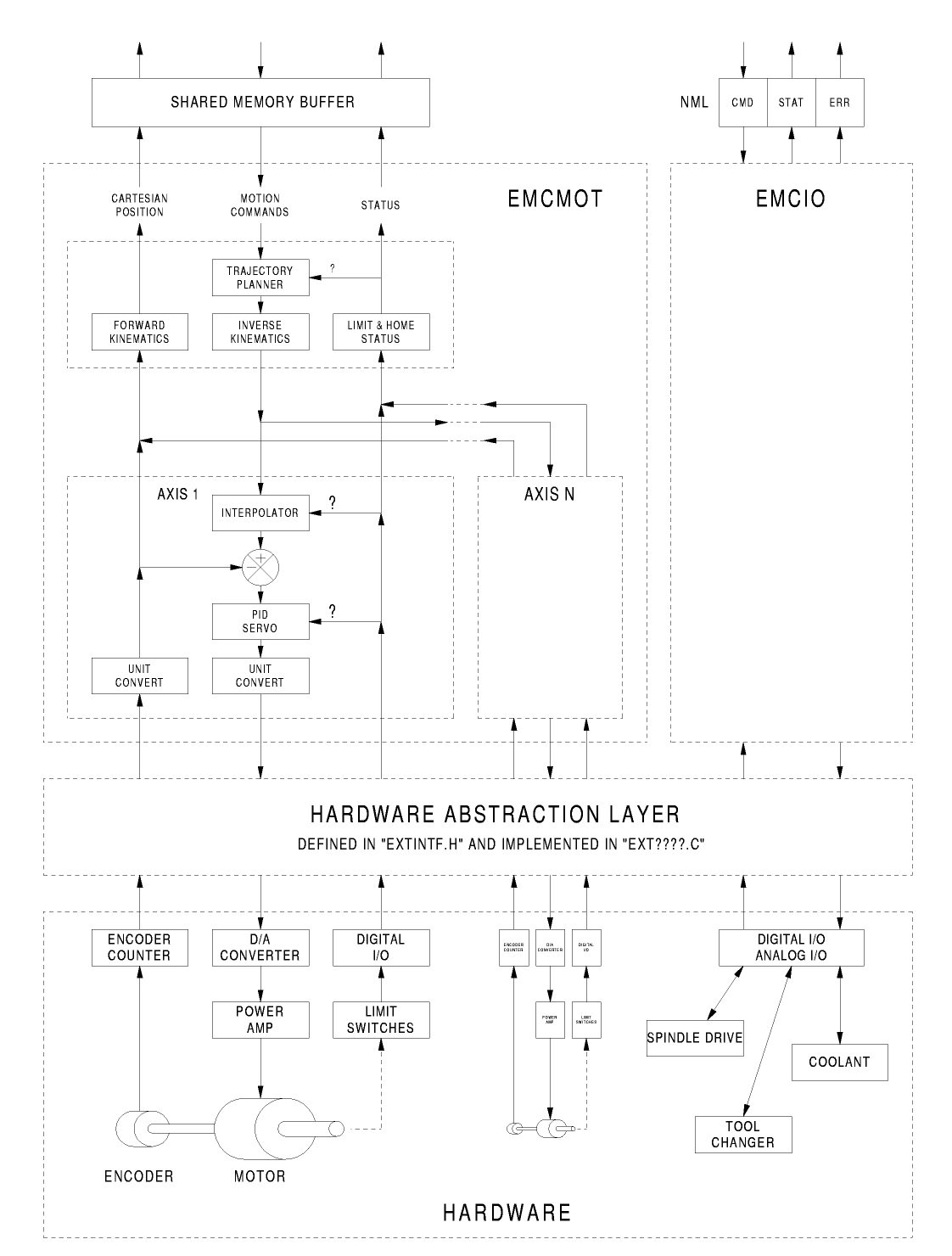

5. Introducción al controlador de movimiento

El controlador de movimiento es un componente de tiempo real. Recibe los comandos de control de movimiento desde las partes en tiempo no-real de LinuxCNC (p. ej. el intérprete de código G/tarea, GUIs, etc.) y ejecuta esos comandos dentro de un contexto de tiempo real. La comunicación desde el contexto en tiempo no-real hacia el contexto en tiempo real ocurre mediante un mecanismo IPC pasa-mensajes que usa memoria compartida, y vía la Capa de abstracción de hardware (HAL).

El estado del controlador de movimiento esta disponible para el resto de LinuxCNC mediante el mismo IPC pasa-mensajes en memoria compartida y a través de HAL.

El controlador de movimiento interactúa con los controladores de motor y otro hardware en tiempo real y no-real usando HAL.

Este documento asume que el lector tiene una comprensión básica de HAL, y comprende términos como pines HAL, señales HAL, etc., por lo que no se explican. Para obtener más información sobre HAL, consulte el Manual HAL. Otro capítulo de este documento entrará eventualmente en las interioridades del propio HAL, pero en este capítulo, solo usamos la API HAL, definida en src/hal/hal.h.

5.1. Módulos controladores de movimiento

La funciones de tiempo real del controlador de movimiento están implementadas con módulos de tiempo real — objetos compartidos en espacio de usuario para sistemas Preempt-RT o módulos de kernel para algunas implementaciones de tiempo real en modo kernel como RTAI:

-

tpmod - planificación de trayectoria

-

homemod - funciones homing

-

motmod - procesa comandos NML y controla hardware vía HAL

-

kinematics module - realiza cinemáticas directas (articulaciones->coordenadas) e inversas (coordenadas->articulaciones)

LinuxCNC se inicia con una secuencia de comandos linuxcnc que lee un archivo de configuración INI e inicia todos los procesos necesarios. Para control de movimiento en tiempo real, la secuencia de comandos primero carga los módulos predeterminados tpmod y homemod y luego carga los módulos de cinemáticas y movimiento de acuerdo con las configuraciones de los archivos HAL especificados en el archivo INI.

En vez de usar los módulos predeterminados, se pueden usar módulos personalizados (compilados por el usuario) de homing o planificación de trayectoria mediante configuraciones en archivo INI u opciones de línea de comandos. Los módulos personalizados deben implementar todas las funciones usadas por los módulos predeterminados. La utilería halcompile puede crear módulos personalizados.

6. Diagrama de bloques y flujo de datos

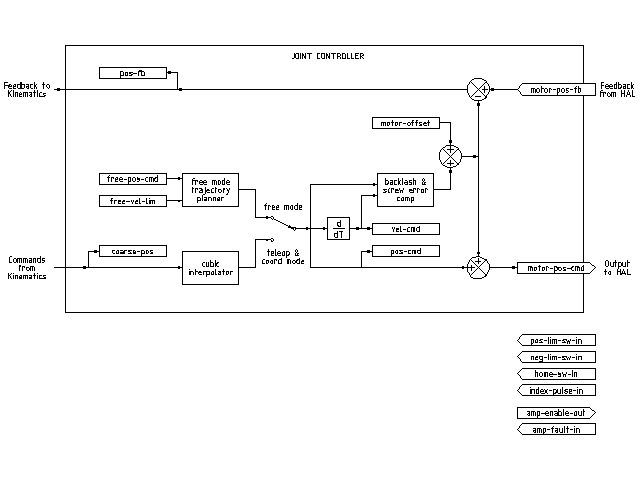

La siguiente figura es un diagrama de bloques de un controlador articular. Hay un controlador por articulación. Los controladores articulares funcionan a un nivel más bajo que la cinemática; un nivel donde todas las articulaciones son completamente independientes. Todos los datos para una articulación está en una sola estructura articular. Algunos miembros de esa estructura son visible en el diagrama de bloques, como coarse_pos, pos_cmd y motor_pos_fb.

La figura anterior muestra cinco de los siete conjuntos de información de posición que forman el flujo principal de datos a través del controlador de movimiento. Las siete formas de datos de posición son las siguientes:

-

emcmotStatus->carte_pos_cmd - Esta es la posición deseada, en coordenadas cartesianas. Se actualiza a tasa traj, no a tasa servo. En modo coord, se determina por el planificador traj. En modo teleop, está determinado por el planificador traj?. En modo libre, es copiado de actualPos, o generado mediante la aplicación de cinemática directa a (2) o (3).

-

emcmotStatus->joints[n].coarse_pos - Esta es la posición deseada, en coordenadas articulares, pero antes de interpolación. Se actualiza a tasa traj, no a tasa servo. En modo coord, se genera aplicando cinematica inversa a (1). En modo teleop, se genera aplicando cinemática inversa a (1). En modo libre, creo que se copia de (3).

-

emcmotStatus->joints[n].pos_cmd - Esta es la posición deseada, en coordenadas articulares, después de interpolación. En cada período servo se genera un nuevo conjunto de estas coordenadas. En modo coord se genera a partir de (2) por el interpolador. En modo teleop, se genera a partir de (2) por el interpolador. En modo free es generado por el planificador de trayectoria de modo libre.

-

emcmotStatus->joints[n].motor_pos_cmd - Esta es la posición deseada, en coordenadas de motor. Las coordenadas del motor se generan agregando compensación de holgura mecánica, compensación de error del tornillo de avance y offset (para homing) a (3). Se genera de la misma manera independientemente del modo, y es la salida al bucle PID u otro bucle de posición.

-

emcmotStatus->joints[n].motor_pos_fb - Esta es la posición real, en coordenadas de motor. Es la entrada de codificadores u otro dispositivo de retroalimentación (o desde codificadores virtuales en máquinas de bucle abierto). Es "generado" por la lectura del dispositivo de retroalimentación.

-

emcmotStatus->joints[n].pos_fb - Esta es la posición real en coordenadas articulares. Se genera restando offsets, compensación de error del tornillo de avance y compensación de holgura mecánica de (5). Se genera de la misma manera, independientemente del modo operativo.

-

emcmotStatus->carte_pos_fb - Esta es la posición real, en coordenadas cartesianas. Se actualiza a tasa traj, no a tasa servo. Idealmente, actualPos siempre se calcularía aplicando cinemática directa a (6). Sin embargo, la cinemática directa puede no estar disponible, o pueden ser inutilizable porque uno o más ejes no están en casa. En ese caso, las opciones son: A) fingirla, copiando (1), o B) admitir que realmente no se conocen las coordenadas cartesianas, y simplemente no actualizar actualPos. Cualquiera que sea el enfoque utilizado, no veo ninguna razón para no hacerlo de la misma manera, independientemente del modo de operación. Yo propondría lo siguiente: si hay cinemática directa, usarla, a menos que no funcionen debido a ejes no-en casa u otros problemas, en cuyo caso hacer (B). Si no hay cinemática directa, hacer (A), ya que de lo contrario actualPos nunca estará actualizada.

7. Homing

7.1. Diagrama de estado de homing

7.2. Otro diagrama de homing

8. Comandos

Los comandos se implementan mediante una gran instrucción switch en la función emcmotCommandHandler(), que se llama a la tasa servo. Más sobre esa función más adelante.

Hay aproximadamente 44 comandos - esta lista todavía está en construcción.

|

Nota

|

La enumeración cmd_code_t, en motion.h, contiene 73 comandos, pero la instrucción switch en command.c contempla sólo 70 comandos (hasta 5/jun/2020). Los comandos ENABLE_WATCHDOG / DISABLE_WATCHDOG están en motion-logger.c. Quizás estén obsoletos. El comando SET_TELEOP_VECTOR solo aparece en motion-logger.c, sin más efecto que su propio log. |

8.1. ABORT

El comando ABORT simplemente detiene todo movimiento. Se puede emitir en cualquier momento y siempre será aceptado. No deshabilita el controlador de movimiento ni cambia ninguna información de estado; simplemente cancela cualquier movimiento que esté actualmente en progreso. Nota al pie:[Parece que el código de nivel superior (TASK y superior) también usa ABORT para borrar fallos. Siempre que haya un fallo persistente (como estar fuera de interruptores hardware de límite), el código de nivel superior envía un flujo constante de ABORTs al controlador de movimiento en su intento de sobrepasar el fallo. Miles de ellos … Eso significa que el controlador de movimiento debe evitar fallos persistentes. Esto necesita ser investigado.]

8.1.1. Requisitos

Ninguno. El comando ABORT siempre se acepta y actúa inmediatamente.

8.1.2. Resultados

En modo libre, los planificadores de trayectoria de modo libre quedan deshabilitados. Esto da como resultado que cada articulación se detenga tan rápido como su límite de aceleración (desaceleración) permita. La parada no está coordinada. En modo teleop, la velocidad cartesiana comandada se establece a cero. No sé exactamente qué tipo de parada resulta (coordinada, descoordinada, etc.), pero lo resolveré finalmente. En modo coord, se le dice al planificador de trayectoria del modo coord que aborte el movimiento actual. De nuevo, no sé el resultado exacto de esto, pero lo documentaré cuando lo resuelva.

8.2. FREE

El comando FREE pone el controlador de movimiento en modo libre. Modo libre significa que cada articulación es independiente de todas las demás articulaciones. Coordenadas cartesianas, poses y cinemáticas se ignoran cuando está en modo libre. En esencia, cada articulación tiene su propio planificador de trayectoria simple, y cada articulación ignora por completo las otras articulaciones. Algunos comandos (como JOG y HOME de articulación) solo funcionan en modo libre. Otros comandos, incluso cualquier cosa que trate con coordenadas cartesianas, no funciona en absoluto en modo libre.

8.2.1. Requisitos

El controlador de comandos no aplica requisitos al comando FREE, siempre será aceptado. Sin embargo, si alguna articulación está en movimiento (GET_MOTION_INPOS_FLAG () == FALSE), entonces el comando será ignorado. Este comportamiento está controlado por un código que ahora se encuentra en la función set_operating_mode() en control.c, ese código debe limpiarse. Creo que el comando no debe ignorarse en silencio, sino que el controlador de comandos debe determinar si se puede ejecutar y devolver un error si no puede.

8.2.2. Resultados

Si la máquina ya está en modo libre, nada. De lo contrario, la máquina se coloca en modo libre. Cada planificador de trayectoria en modo libre de articulación se inicializa con la ubicación actual de la articulación, pero los planificadores no están habilitados y las articulaciones están estacionadas.

8.3. TELEOP

El comando TELEOP coloca la máquina en modo de teleoperación. En teleop modo, el movimiento de la máquina se basa en coordenadas cartesianas utilizando cinemática, en lugar de en articulaciones individuales como en modo libre. Sin embargo, el planificador de trayectoria per se no se usa, en cambio el movimiento es controlado por un vector de velocidad. El movimiento en modo teleop es muy parecido a trotar, excepto que se hace en espacio cartesiano en lugar de espacio de articulación. En una máquina con cinemática trivial, hay pequeña diferencia entre el modo teleop y el modo libre, y las GUI para esas máquinas podrían ni siquiera emitir este comando. Sin embargo, para máquinas no triviales como robots y hexápodos, el modo teleop se utiliza para la mayoría de los movimientos tipo jog ordenados por usuario.

8.3.1. Requisitos

El controlador de comandos rechazará el comando TELEOP con un error mensaje si la cinemática no se puede activar porque una o más articulaciones no han sido dirigidas. Además, si alguna articulación está en movimiento (GET_MOTION_INPOS_FLAG () == FALSE), entonces el comando será ignorado (sin mensaje de error). Este comportamiento está controlado por un código que ahora esta ubicado en la función set_operating_mode() en control.c. Creo que el comando no debe ser ignorado en silencio, sino el controlador del comando debe determinar si se puede ejecutar y devolver un error si no puede.

8.3.2. Resultados

Si la máquina ya está en modo teleop, nada. De lo contrario la máquina se coloca en modo teleop. El código cinemático está activado, los interpoladores son drenados y enjuagados, y los comandos de velocidad cartesiana se ponen a cero.

8.4. COORD

El comando COORD coloca la máquina en modo coordinado. En modo coord, el movimiento de la máquina se basa en coordenadas cartesianas utilizando cinemáticas, en lugar de articulaciones individuales como en modo libre. Además, el planificador de trayectoria principal se utiliza para generar movimiento, con base en comandos LINE, CIRCLE y/o PROBE en cola. El modo coord es el modo que se usa al ejecutar un programa de código G.

8.4.1. Requisitos

El controlador de comandos rechazará el comando COORD con un error mensaje si la cinemática no se puede activar porque una o más articulaciones no han sido dirigidas. Además, si alguna articulación está en movimiento (GET_MOTION_INPOS_FLAG () == FALSE), entonces el comando será ignorado (sin mensaje de error). Este comportamiento está controlado por un código que ahora esta ubicado en la función set_operating_mode() en control.c. Creo que el comando no debe ser ignorado en silencio, sino que el controlador de comando debe determinar si se puede ejecutar y devolver un error si no puede.

8.4.2. Resultados

Si la máquina ya está en modo coord, nada. De lo contrario, la máquina se coloca en modo coord. El código cinemático está activado, los interpoladores son drenados y enjuagados, y las colas de planificador de trayectoria son vaciadas. El planificador de trayectoria está activo y en espera de un comando LINE, CIRCLE o PROBE.

8.5. ENABLE

El comando ENABLE habilita el controlador de movimiento.

8.5.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado.

8.5.2. Resultados

Si el controlador ya está habilitado, nada. Si no, el controlador es habilitado. Las colas y los interpoladores se drenan. Cualquier movimiento u operación de homing se finaliza. Las salidas amp-enable asociadas con articulaciones activas se encienden. Si no hay cinemática directa disponible, la máquina se cambia al modo libre.

8.6. DISABLE

El comando DISABLE deshabilita el controlador de movimiento.

8.6.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado.

8.6.2. Resultados

Si el controlador ya está deshabilitado, nada. Si no, el controlador está desactivado. Las colas y los interpoladores se drenan. Cualquier movimiento u operación de homing se finaliza. Las salidas amp-enable asociadas con las articulaciones activas son apagadas. Si no hay cinemática directa disponible, la máquina se cambia al modo libre.

8.7. ENABLE_AMPLIFIER

El comando ENABLE_AMPLIFIER activa la salida de habilitación del amplificador para un amplificador de salida única, sin cambiar nada más. Puede ser usado para habilitar un controlador de velocidad del husillo.

8.7.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado.

8.7.2. Resultados

Actualmente nada. (Una llamada a la antigua función extAmpEnable esta actualmente comentada). Eventualmente establecerá el pin HAL de habilitación del amplificador a TRUE.

8.8. DISABLE_AMPLIFIER

El comando DISABLE_AMPLIFIER apaga la salida de habilitación del amplificador para un solo amplificador, sin cambiar nada más. De nuevo, útil para controladores de velocidad del husillo.

8.8.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado.

8.8.2. Resultados

Actualmente nada. (Una llamada a la antigua función extAmpEnable está actualmente comentada). Eventualmente establecerá el pin HAL de habilitación del amplificador en FALSE.

8.9. ACTIVATE_JOINT

El comando ACTIVATE_JOINT activa todos los cálculos asociados con una sola articulación, pero no cambia el pin de salida de habilitación del amplificador de la articulación.

8.9.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado.

8.9.2. Resultados

Los cálculos para la articulación especificada están habilitados. El pin de habilitación del amplificador no se cambia, sin embargo, cualquier comando ENABLE o DISABLE posterior modificará el pin de habilitación del amplificador de la articulación.

8.10. DEACTIVATE_JOINT

El comando DEACTIVATE_JOINT desactiva todos los cálculos asociados con una sola articulación, pero no cambia la salida del pin de habilitación del amplificador de la articulación.

8.10.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado.

8.10.2. Resultados

Los cálculos para la articulación especificada están habilitados. El pin de habilitación del amplificador no se cambia, y los comandos ENABLE o DISABLE subsecuentes no modificarán el pin de habilitación del amplificador de la articulación.

8.11. ENABLE_WATCHDOG

El comando ENABLE_WATCHDOG habilita un perro guardián basado en hardware (si está presente).

8.11.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado.

8.11.2. Resultados

Actualmente nada. El antiguo watchdog era una cosa extraña que utilizaba una tarjeta de sonido específica. Es posible que en el futuro se diseñe una nueva interfaz de watchdog.

8.12. DISABLE_WATCHDOG

El comando DISABLE_WATCHDOG deshabilita un perro guardián basado en hardware (si está presente).

8.12.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado.

8.12.2. Resultados

Actualmente nada. El antiguo watchdog era una cosa extraña que utilizaba una tarjeta de sonido específica. Es posible que en el futuro se diseñe una nueva interfaz de watchdog.

8.13. PAUSE

El comando PAUSE detiene el planificador de trayectoria. No tiene efecto en modo libre o teleop. En este punto no sé si detiene todo el movimiento inmediatamente, o si completa el movimiento actual y luego se detiene antes de jalar otro movimiento de la cola.

8.13.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado.

8.13.2. Resultados

El planificador de trayectoria hace una pausa.

8.14. RESUME

El comando RESUME reinicia el planificador de trayectoria si está en pausa. No tiene efecto en modo libre o teleop, o si el planificador no está en pausa.

8.14.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado.

8.14.2. Resultados

Se reanuda el planificador de trayectoria.

8.15. STEP

El comando STEP reinicia el planificador de trayectoria si está en pausa, y le dice al planificador que se detenga nuevamente cuando llegue a un punto específico. No tiene efecto en modo libre o teleop. En este punto no se exactamente cómo funciona esto. Agregaré más documentación aquí cuando excave más profundo en el planificador de trayectoria.

8.15.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado.

8.15.2. Resultados

El planificador de trayectoria se reanuda y luego se detiene cuando llega a un punto específico.

8.16. SCALE

El comando SCALE escala todos los límites de velocidad y comandos por una cantidad especificada. Se utiliza para implementar la anulación de velocidad de alimentación y otros funciones similares. El escalado funciona en modo libre, teleop y coord, y afecta todo, incluidas las velocidades de homing, etc. Sin embargo, los límites individuales de velocidad de articulación no se ven afectados.

8.16.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado.

8.16.2. Resultados

Todos los comandos de velocidad son escalados por la constante especificada.

8.17. OVERRIDE_LIMITS

El comando OVERRIDE_LIMITS evita que los límites se disparen hasta el fin del siguiente comando JOG. Normalmente se usa para permitir que una máquina salga de un interruptor de límite después de disparar. (El comando puede usarse en realidad para anular límites o para cancelar una anulación anterior.)

8.17.1. Requisitos

Ninguna. El comando puede emitirse en cualquier momento y siempre será aceptado. (Creo que solo debería funcionar en modo libre.)

8.17.2. Resultados

Los límites en todas las articulaciones se anulan hasta el final del próximo comando JOG. (Esto está roto actualmente … una vez que se recibe un comando OVERRIDE_LIMITS, los límites se ignoran hasta que otro comando OVERRIDE_LIMITS los vuelve a habilitar.)

8.18. HOME

El comando HOME inicia una secuencia de homing en una articulación especificada. La secuencia homing real está determinada por unos parámetros de configuración, y puede variar desde simplemente establecer la posición actual a cero, hasta una búsqueda en varias etapas de un interruptor de casa y pulso de índice, seguido de un movimiento a una ubicación de casa arbitraria. Para más información sobre la secuencia de homing consultar el Manual del integrador.

8.18.1. Requisitos

El comando se ignorará en silencio a menos que la máquina esté en modo libre.

8.18.2. Resultados

Se anula cualquier trote o movimiento de articulación y se inicia la secuencia de homing.

8.19. JOG_CONT

El comando JOG_CONT inicia un trote continuo en una sola articulación. Se genera un trote continuo al establecer la posición objetivo del planificador de trayectoria en modo libre a un punto más allá del final del rango de carrera de la articulación. Esto asegura que el planificador moverá constantemente hasta que sea detenido por los límites de articulación o por un comando ABORT. Normalmente, una GUI envía un comando JOG_CONT cuando el usuario presiona un botón de trote, y un ABORT al soltar el botón.

8.19.1. Requisitos

El controlador de comandos rechazará el comando JOG_CONT con un mensaje de error si la máquina no está en modo libre, o si alguna articulación está en movimiento (GET_MOTION_INPOS_FLAG () == FALSE), o si el movimiento no está habilitado. También ignorará silenciosamente el comando si la articulación ya está en (o más allá de) su límite y el trote ordenado lo empeoraría.

8.19.2. Resultados

El planificador de trayectoria de modo libre para la articulación identificada por emcmotCommand->eje es activado, con una posición destino más allá del final de carrera de la articulación, y un límite de velocidad de emcmotCommand->vel. Este comienza el movimiento de la articulación, y el movimiento continuará hasta ser detenido por un comando ABORT o al alcanzar un límite. El planificador de modo libre acelera al límite de aceleración de articulación al comienzo del movimiento, y desacelerará al límite de aceleración de articulación cuando se detenga.

8.20. JOG_INCR

El comando JOG_INCR inicia un trote gradual en una sola articulación. Los trotes incrementales son acumulativos, en otras palabras, emitir dos comandos JOG_INCR pidiendo cada uno 0.100 pulgadas de movimiento resultarán en 0.200 pulgadas de recorrido, incluso si el segundo comando se emite antes que termine el primero. Normalmente, los trotes incrementales se detienen cuando ya recorrieron la distancia deseada, sin embargo, también se detienen cuando topan con un límite, o con un comando ABORT.

8.20.1. Requisitos

El controlador de comandos rechazará silenciosamente el comando JOG_INCR si la máquina no está en modo libre, o si alguna articulación está en movimiento (GET_MOTION_INPOS_FLAG () == FALSE), o si el movimiento no está habilitado. También ignorará silenciosamente el comando si la articulación ya está en (o más allá de) su límite y el trote ordenado lo empeoraría.

8.20.2. Resultados

El planificador de trayectoria de modo libre para la articulación identificada por emcmotCommand->eje está activado, la posición destino es incrementada/decrementada por emcmotCommand->offset, y el límite de velocidad se establece en emcmotCommand->vel. El planificador de trayectoria de modo libre generará un movimiento trapezoidal suave desde la posición actual hasta la posición destino. El planificador puede manejar correctamente los cambios en posición objetivo que ocurran mientras el movimiento este en progreso, por lo que se pueden emitir múltiples comandos JOG_INCR en sucesión rápida. El planificador de modo libre acelera al límite de aceleración de articulación al comienzo del movimiento, y desacelerará al límite de aceleración de articulación para detenerse en el posición destino.

8.21. JOG_ABS

El comando JOG_ABS inicia un trote absoluto en una sola articulación. Un trote absoluto es un simple movimiento a una ubicación específica en coordenadas articulares. Normalmente los trotes absolutos se detienen cuando alcanzan la ubicación deseada, sin embargo, también se detienen cuando alcanzan un límite, o con un comando ABORT.

8.21.1. Requisitos

El controlador de comandos rechazará silenciosamente el comando JOG_ABS si la máquina no está en modo libre, o si alguna articulación está en movimiento (GET_MOTION_INPOS_FLAG () == FALSE), o si el movimiento no está habilitado. También ignorará silenciosamente el comando si la articulación ya está en (o más allá de) su límite y el trote ordenado lo empeoraría.

8.21.2. Resultados

El planificador de trayectoria de modo libre para la articulación identificada por emcmotCommand->axis está activado, la posición destino se establece a emcmotCommand->offset, y el límite de velocidad se establece a emcmotCommand->vel. El planificador de trayectoria de modo libre generará un movimiento trapezoidal suave desde la posición actual hasta la posición destino. El planificador puede manejar correctamente los cambios a la posición destino que sucedan mientras el movimiento está en progreso. Si varios comandos JOG_ABS se emiten en sucesión rápida, cada nuevo comando cambia la posición destino y la máquina pasa a la posición final ordenada. El planificador de modo libre acelera al límite de aceleración de articulación en el comienzo del movimiento, y desacelerará al límite de aceleración de articulación para detenerse en la posición destino.

8.22. SET_LINE

El comando SET_LINE agrega una línea recta a la cola del planificador de trayectoria.

(More later)

8.23. SET_CIRCLE

El comando SET_CIRCLE agrega un movimiento circular a la cola del planificador de trayectoria.

(More later)

8.24. SET_TELEOP_VECTOR

El comando SET_TELEOP_VECTOR indica al controlador de movimiento que se mueva a lo largo de un vector específico en el espacio cartesiano.

(More later)

8.25. PROBE

El comando PROBE indica al controlador de movimiento que se mueva hacia un punto específico en el espacio cartesiano, deteniendo y grabando su posición si se dispara la entrada de la sonda.

(More later)

8.26. CLEAR_PROBE_FLAG

El comando CLEAR_PROBE_FLAG se usa para restablecer la entrada de la sonda en preparación para un comando PROBE. (Pregunta: ¿por qué el comando PROBE no debería restablecer automáticamente la entrada?)

(More later)

8.27. SET_xix

Hay aproximadamente 15 comandos SET_xxx, donde xxx es el nombre de algún parámetro de configuración. Se anticipa que habrá varios comandos SET más a medida que se agregan más parámetros. Me gustaría encontrar una forma más limpia de establecer y leer los parámetros de configuración. Los métodos existentes requieren que se agreguen muchas líneas de código a múltiples archivos cada vez que se agrega un parámetro. Gran parte de ese código es idéntico o casi idéntico para cada parámetro.

9. Compensación de error de tornillo y holgura mecánica

FIXME Compensación de holguras y errores de tornillos

10. Controlador de tareas (EMCTASK)

10.1. Estado

Una tarea tiene tres estados internos posibles: E-stop, E-stop Reset, y Machine on.

11. Controlador E/S (EMCIO)

El controlador de E/S es parte de TASK. Interactúa con E/S externas usando pines HAL.

Actualmente ESTOP/Enable, el refrigerante, y el cambio de herramienta se manejan con iocontrol. Estos son eventos de velocidad relativamente baja; las E/S coordinadas de alta velocidad se manejan en motion.

emctaskmain.cc envía comandos de E/S mediante taskclass.cc.

Proceso del bucle principal de iocontrol:

-

comprueba si las entradas HAL han cambiado

-

comprueba si read_tool_inputs() indica que el cambio de herramienta ha finalizado y establece emcioStatus.status

12. Interfaces de usuario

Interfaces de usuario FIXME

13. Introducción a libnml

libnml se deriva de rcslib del NIST sin todo el soporte multi-plataformas. Muchas de las envolturas de código específico de plataforma han sido eliminadas, junto con gran parte del código que no es requerido por LinuxCNC. Se espera que quede suficiente compatibilidad con rcslib para que las aplicaciones puedan implementarse en plataformas que no sean Linux y aún ser capaz de comunicarse con LinuxCNC.

Este capítulo no pretende ser una guía definitiva para usar libnml (o rcslib); en cambio proporcionará eventualmente una visión general de cada clase C++ y sus funciones miembro. Inicialmente, la mayoría de estas notas se agregarán como comentarios aleatorios a medida que el código se analice y modifique.

14. LinkedList

Clase base para mantener una lista enlazada. Este es uno de los principales bloques de construcción utilizados para pasar mensajes NML y una variedad de estructuras de datos internas.

15. LinkedListNode

Clase base para producir una lista enlazada. Su propósito es mantener punteros a los nodos anteriores y siguientes, puntero a los datos y el tamaño de los datos.

No asigna memoria para el almacenamiento de datos.

16. SharedMemory

Proporciona un bloque de memoria compartida junto con un semáforo (heredado de la clase Semaphore). La creación y destrucción del semáforo es manejado por el constructor y destructor SharedMemory.

17. ShmBuffer

Clase para pasar mensajes NML entre procesos locales mediante memoria intermedia de uso compartido. Gran parte del funcionamiento interno se hereda de la clase CMS.

18. Timer

La clase Timer proporciona un temporizador periódico limitado solo por la resolución del reloj del sistema. Si, por ejemplo, un proceso necesita ser ejecutado cada 5 segundos, independientemente del tiempo que lleve ejecutar el proceso, el siguiente fragmento de código muestra cómo hacerlo:

main() { timer = new Timer(5.0); /* Inicializa un temporizador con un ciclo de 5 segundos */ while(0) { /* Hacer algún proceso */ timer.wait(); /* Espera hasta el siguiente intervalo de 5 segundos */ } delete timer; }

19. Semaphore

La clase Semaphore proporciona un método de exclusiones mutuas para acceder a un recurso compartido. La función para obtener un semáforo puede bloquear hasta que el acceso esté disponible, regresar después de un tiempo de espera o regresar inmediatamente con o sin obtener el semáforo. El constructor creará un semáforo o adjuntará a uno existente si la ID ya está en uso.

Semaphore::destroy() debe ser invocado solo por el último proceso.

20. CMS

En el corazón de libnml está la clase CMS. Contiene la mayor parte de las funciones utilizadas por libnml y finalmente NML. Muchas de las funciones internas se sobrecargan para permitir métodos de paso de datos dependientes de hardware específico. Al final, todo gira en torno a un bloque central de memoria (denominado "búfer de mensajes" o simplemente búfer). Este búfer puede existir como un bloque de memoria compartida accedido por otros procesos CMS/NML, o un búfer local y privado para la transmisión de datos por red o interfaces seriales.

El búfer se asigna dinámicamente en tiempo de ejecución para permitir una mayor flexibilidad del subsistema CMS/NML. El tamaño del búfer debe ser suficientemente grande para acomodar el mensaje más grande, una pequeña cantidad para uso interno y permitir que el mensaje se codifique si se elige esta opción (los datos codificados se cubrirán más adelante). La figura siguiente es una vista interna del espacio del búfer.

La clase base de CMS es la principal responsable de crear las vías de comunicación e interfazar con el sistema operativo.

21. Formato del archivo de configuración

La configuración NML consta de dos tipos de formatos de línea. Uno para búfers y un segundo para procesos que se conectan a los búfers.

21.1. Línea de búfer

El formato NIST original de la línea de búfer es:

-

B nombre tipo host tamaño neut RPC# búfer# máx_procs clave [configuraciones específicas por tipo]

-

B- identifica la línea como una configuración de búfer.

-

nombre- es el identificador del búfer.

-

tipo- describe el tipo de búfer: SHMEM, LOCMEM, FILEMEM, PHANTOM o GLOBMEM.

-

host- es una dirección IP o un nombre de host para el servidor NML

-

tamaño- es el tamaño del búfer

-

neut- un booleano para indicar si los datos en el búfer están codificados en un formato independiente de la máquina, o sin formato.

-

RPC#- obsoleto - marcador de posición retenido solo para compatibilidad con versiones anteriores.

-

búfer#- un número identificador único que se usa si un servidor controla varios búfers.

-

máx_procs- número máximo de procesos permitidos para conectarse a este búfer.

-

clave - es un identificador numérico para un búfer de memoria compartida

21.2. Configuraciones específicas por tipo

El tipo de búfer implica opciones de configuración adicionales mientras que el sistema operativo anfitrión impide ciertas combinaciones. En una tentativa de concretar la documentación publicada en un formato coherente, solo será cubierto el tipo de buffer SHMEM.

-

mutex=os_sem- modo predeterminado para proporcionar el semáforo de bloqueo de la memoria intermedia.

-

mutex=none- no utilizado

-

mutex=no_interrupts - no aplicable en un sistema Linux

-

mutex=no_switching - no aplicable en un sistema Linux

-

mutex=mao split- divide el búfer en la mitad (o más) y permite que un proceso acceda a una parte del búfer mientras que un segundo proceso está escribiendo en la otra parte.

-

TCP=(número de puerto)- especifica qué puerto de red utilizar.

-

UDP =(número de puerto) - ídem

-

STCP =(número de puerto) - ídem

-

serialPortDevName=(puerto serie) - sin documentar.

-

passwd=file_name.pwd- agrega una capa de seguridad al búfer requiriendo que cada proceso proporcione una contraseña.

-

bsem- la documentación del NIST implica una clave para un semáforo de bloqueo, y si bsem=-1, se evitan los bloqueos de lectura.

-

queue- permite pasar mensajes en cola.

-

ascii - Codifica mensajes en formato de texto plano

-

disp- codifica los mensajes en un formato adecuado para mostrarlos (???)

-

xdr- codifica mensajes en Representación de Datos Externos. (Ver rpc/xdr.h para más detalles).

-

diag- habilita almacenado de diagnósticos en el búfer (¿temporizaciones y recuentos de bytes?)

21.3. Línea de proceso

El formato NIST original de la línea de proceso es:

P nombre búfer tipo host ops servidor tiempo master c_num [configuraciones específicas por tipo]

-

P- identifica esta línea como una configuración de proceso.

-

nombre- es el identificador del proceso.

-

búfer - es uno de los búfers definidos en otra parte del archivo de configuración.

-

tipo- define si este proceso es local o remoto en relación con el búfer.

-

host- especifica en qué parte de la red se está ejecutando este proceso.

-

ops- proporciona al proceso acceso de solo lectura, solo escritura o de lectura/escritura al búfer.

-

servidor- especifica si este proceso ejecutará un servidor para este búfer.

-

tiempo - establece las características de tiempo de espera para los accesos al búfer.

-

master - indica si este proceso es responsable de crear y destruir el búfer.

-

c_num - un número entero entre cero y (máx_procs -1)

21.4. Comentarios de configuración

Algunas de las combinaciones de configuración no son válidas, mientras que otras implican ciertas restricciones. En un sistema Linux GLOBMEM es obsoleto, mientras que PHANTOM solo es realmente útil en la etapa de prueba de una aplicación; igualmente para FILEMEM. LOCMEM es de poca utilidad para una aplicación multiproceso, y solo ofrece ventajas limitadas de rendimiento sobre SHMEM. Esto deja a SHMEM como el único tipo de búfer para usar con LinuxCNC.

La opción neut solo se usa en un sistema multiprocesador donde arquitecturas diferentes (e incompatibles) comparten un bloque de memoria. La probabilidad de ver un sistema de este tipo fuera de un museo o lugar de investigación es remoto y solo es relevante para buffers GLOBMEM.

El número RPC está documentado como obsoleto y solo se conserva por razones de compatibilidad.

Con un nombre de búfer único, tener una identidad numérica parece ser inútil. Es necesario revisar el código para identificar la lógica. Asimismo, el campo clave parece ser redundante, y podría derivarse del nombre del búfer.

El propósito de limitar el número de procesos permitidos para conectarse a cualquier búfer no está claro a partir de la documentación existente y del código fuente original. Permitir un número no especificado de procesos para conectarse a un búfer no es más difícil de implementar.

Los tipos mutex se reducen a uno de estos dos; el predeterminado "os_sem" o "mao split". La mayoría de los mensajes NML son relativamente cortos y se pueden copiar hacia o desde el búfer con retrasos mínimos, por lo que las lecturas divididas no son esenciales.

La codificación de datos solo es relevante cuando se transmite a un proceso remoto - Usar TCP o UDP implica codificación XDR. La codificación ASCII puede tener algún uso en diagnósticos o para pasar datos a un sistema integrado que no implementa NML.

Los protocolos UDP tienen menos verificaciones en los datos y permiten descartar un porcentaje de paquetes. TCP es más confiable, pero es relativamente más lento.

Si LinuxCNC se va a conectar a una red, se esperaría que sea local y detrás de un cortafuegos. La única razón para permitir el acceso a LinuxCNC a través de internet sería para diagnósticos remotos. Esto puede lograrse de manera mucho más segura utilizando otros medios, tal vez por una interfaz web.

El comportamiento exacto cuando el tiempo de espera se establece en cero o un valor negativo no está claro desde los documentos del NIST. Solo se mencionan valores INF y positivos. Sin embargo, enterrado en el código fuente de rcslib, parece aplicar lo siguiente:

- tiempo > 0

-

Bloqueo de acceso hasta que se alcanza el intervalo de tiempo de espera o el acceso al búfer esté disponible.

- tiempo = 0

-

El acceso al búfer solo es posible si no hay otro proceso que esté leyendo o escribiendo en ese momento.

- tiempo < 0 o INF

-

El acceso está bloqueado hasta que el búfer esté disponible.

22. Clase base NML

Expande las listas y la relación entre NML, NMLmsg y las clases cms de nivel inferior.

No debe confundirse con NMLmsg, RCS_STAT_MSG o RCS_CMD_MSG.

NML es responsable de analizar el archivo de configuración, configurar los búfers cms y es el mecanismo para enrutar mensajes al(los) búfer(s) correcto(s). Para hacer esto, NML crea varias listas para:

-

búferes cms creados o conectados.

-

procesos y búferes a las que se conectan

-

una larga lista de funciones de formato para cada tipo de mensaje

Este último elemento es probablemente el núcleo de gran parte de la desalineación de libnml/rcslib y NML en general. Cada mensaje que se pasa a través de NML requiere que se adjunte una cierta cantidad de información además de los datos reales. Para hacer esto, se invocan en secuencia varias funciones de formato para ensamblar fragmentos del mensaje general. Las funciones de formato incluirán NML_TYPE, MSG_TYPE, además de los datos declarados en clases NMLmsg derivadas. Los cambios en el orden en que se llaman las funciones de formato y también las variables pasadas pueden romper la compatibilidad con rcslib si se hacen mal. Hay razones para mantener la compatibilidad con rcslib y buenas razones para alterar el código. La pregunta es ¿qué conjunto de razones son primordiales?

22.1. Interioridades de NML

22.1.1. Constructor NML

NML::NML() analiza el archivo de configuración y lo almacena en una lista enlazada para ser pasada a constructores cms en líneas simples. Es la función del constructor NML para llamar al constructor cms relevante para cada búfer y mantener una lista de los objetos cms y los procesos asociados con cada búfer.

NML puede interactuar con cms desde los punteros almacenados en las listas y es por esto que Doxygen no muestra las relaciones reales involucradas.

|

Nota

|

La configuración se almacena en la memoria antes de pasar un puntero a una línea específica para el constructor cms. El constructor cms analiza luego la línea nuevamente para extraer un par de variables … Tendría más sentido hacer TODO el análisis y guardar las variables en una estructura que sea pasada al constructor cms. Esto eliminaría la manipulación de cadenas y reduciría el código duplicado en cms … |

22.1.2. Lectura/escritura NML

Las llamadas a NML::read y NML::write realizan tareas similares en el modo de procesar el mensaje; la única variación real está en el dirección del flujo de datos.

Una llamada a la función de lectura primero obtiene datos del búfer y luego llama a format_output(), mientras que una función de escritura llamaría a format_input() antes de pasar los datos al búfer. Dentro de format_xxx() se realiza el trabajo de construir o deconstruir el mensaje. Una lista de funciones variadas se llama a su vez para colocar varias partes del encabezado NML (que no debe confundirse con el encabezado cms) en el orden correcto - La última función llamada es emcFormat() en emc.cc.

22.1.3. Relaciones NMLmsg y NML

NMLmsg es la clase base de la que se derivan todas las clases de mensajes. Cada clase de mensaje debe tener un ID único definido (y pasado al constructor) y también una función update(*cms). update() será llamado por las funciones de lectura/escritura NML cuando se llama al formateador NML - El puntero al formateador habrá sido declarado en el constructor NML en algún momento. En virtud de las listas enlazadas que crea NML, puede seleccionar el puntero cms que se pasa al formateador y, por tanto, que búfer se utilizará.

23. Agregar comandos NML personalizados

LinuxCNC es bastante impresionante, pero algunas partes necesitan algunos ajustes. Como ya sabe, la comunicación se realiza a través de canales NML. Los datos enviados a través de tales canales es una de las clases definidas en emc.hh (implementado en emc.cc). Si alguien necesita un tipo de mensaje que no existe, debería seguir estos pasos para agregar uno nuevo. (El mensaje que se agrega en el ejemplo se llama EMC_IO_GENERIC (hereda EMC_IO_CMD_MSG (hereda RCS_CMD_MSG)))

-

agregar la definición de la clase EMC_IO_GENERIC a emc2/src/emc/nml_intf/emc.hh

-

agregar la definición de tipo: #define EMC_IO_GENERIC_TYPE \((NMLTYPE) 1605)

-

(Se elige 1605 porque esta disponible) en emc2/src/emc/nml_intf/emc.hh

-

-

agregar el caso EMC_IO_GENERIC_TYPE a emcFormat en emc2/src/emc/nml_intf/emc.cc

-

agregar el caso EMC_IO_GENERIC_TYPE a emc_symbol_lookup en emc2/src/emc/nml_intf/emc.cc

-

agregar la función EMC_IO_GENERIC::update a emc2/src/emc/nml_intf/emc.cc

Al recompilar, el nuevo mensaje debería estar allí. La siguiente parte es enviar tales mensajes desde algún lugar y recibirlos en otro lugar, y hacer algunas cosas con eso.

24. La tabla de herramientas y el cambiador de herramientas

LinuxCNC interactúa con el hardware del cambiador de herramientas y tiene una abstracción interna del mismo. LinuxCNC gestiona la información de la herramienta en un archivo de tabla de herramientas.

24.1. Abstracción del cambiador de herramientas en LinuxCNC

LinuxCNC supports two kinds of toolchanger hardware, called nonrandom and random. The INI setting [EMCIO]RANDOM_TOOLCHANGER controls which of these kinds of hardware LinuxCNC thinks it is connected to.

24.1.1. Nonrandom Toolchangers

Nonrandom toolchanger hardware puts each tool back in the pocket it was originally loaded from.

Examples of nonrandom toolchanger hardware are the "manual" toolchanger, lathe tool turrents, and rack toolchangers.

When configured for a nonrandom toolchanger, LinuxCNC does not change the pocket number in the tool table file as tools are loaded and unloaded. Internal to LinuxCNC, on tool change the tool information is copied from the tool table’s source pocket to pocket 0 (which represents the spindle), replacing whatever tool information was previously there.

|

Nota

|

In LinuxCNC configured for nonrandom toolchanger, tool 0 (T0) has special meaning: "no tool". T0 may not appear in the tool table file, and changing to T0 will result in LinuxCNC thinking it has got an empty spindle. |

24.1.2. Random Toolchangers

Random toolchanger hardware swaps the tool in the spindle (if any) with the requested tool on tool change. Thus the pocket that a tool resides in changes as it is swapped in and out of the spindle.

An example of random toolchanger hardware is a carousel toolchanger.

When configured for a random toolchanger, LinuxCNC swaps the pocket number of the old and the new tool in the tool table file when tools are loaded. Internal to LinuxCNC, on tool change, the tool information is swapped between the tool table’s source pocket and pocket 0 (which represents the spindle). So after a tool change, pocket 0 in the tool table has the tool information for the new tool, and the pocket that the new tool came from has the tool information for the old tool (the tool that was in the spindle before the tool change), if any.

|

Nota

|

If LinuxCNC is configured for random toolchanger, tool 0 (T0) has no special meaning. It is treated exactly like any other tool in the tool table. It is customary to use T0 to represent "no tool" (i.e., a tool with zero TLO), so that the spindle can be conveniently emptied when needed. |

24.2. The Tool Table

LinuxCNC keeps track of tools in a file called the tool table. The tool table records the following information for each tool:

- tool number

-

An integer that uniquely identifies this tool. Tool numbers are handled differently by LinuxCNC when configured for random and nonrandom toolchangers:

-

When LinuxCNC is configured for a nonrandom toolchanger this number must be positive. T0 gets special handling and is not allowed to appear in the tool table.

-

When LinuxCNC is configured for a random toolchanger this number must be non-negative. T0 is allowed in the tool table, and is usually used to represent "no tool", i.e. the empty pocket.

-

- pocket number

-

An integer that identifies the pocket or slot in the toolchanger hardware where the tool resides. Pocket numbers are handled differently by LinuxCNC when configured for random and nonrandom toolchangers:

-

When LinuxCNC is configured for a nonrandom toolchanger, the pocket number in the tool file can be any positive integer (pocket 0 is not allowed). LinuxCNC silently compactifies the pocket numbers when it loads the tool file, so there may be a difference between the pocket numbers in the tool file and the internal pocket numbers used by LinuxCNC-with-nonrandom-toolchanger.

-

When LinuxCNC is configured for a random toolchanger, the pocket numbers in the tool file must be between 0 and 1000, inclusive. Pockets 1-1000 are in the toolchanger, pocket 0 is the spindle.

-

- diameter

-

Diameter of the tool, in machine units.

- tool length offset

-

Tool length offset (also called TLO), in up to 9 axes, in machine units. Axes that don’t have a specified TLO get 0.

24.3. G-codes affecting tools

The G-codes that use or affect tool information are:

24.3.1. Txxx

Tells the toolchanger hardware to prepare to switch to a specified tool xxx.

Handled by Interp::convert_tool_select().

-

The machine is asked to prepare to switch to the selected tool by calling the Canon function

SELECT_TOOL()with the tool number of the requested tool.-

(saicanon) No-op.

-

(emccanon) Builds an

EMC_TOOL_PREPAREmessage with the requested pocket number and sends it to Task, which sends it on to IO. IO gets the message and asks HAL to prepare the pocket by settingiocontrol.0.tool-prep-pocket,iocontrol.0.tool-prep-number, andiocontrol.0.tool-prepare. IO then repeatedly callsread_tool_inputs()to poll the HAL piniocontrol.0.tool-prepared, which signals from the toolchanger hardware, via HAL, to IO that the requested tool prep is complete. When that pin goes True, IO setsemcioStatus.tool.pocketPreppedto the requested tool’s pocket number.

-

-

Back in interp,

settings->selected_pocketis assigned the tooldata index of the requested tool xxx.

|

Nota

|

The legacy names selected_pocket and current_pocket actually reference a sequential tooldata index for tool items loaded from a tool table ([EMCIO]TOOL_TABLE) or via a tooldata database ([EMCIO]DB_PROGRAM). |

24.3.2. M6

Tells the toolchanger to switch to the currently selected tool (selected by the previous Txxx command).

Handled by Interp::convert_tool_change().

-

The machine is asked to change to the selected tool by calling the Canon function

CHANGE_TOOL()withsettings->selected_pocket(a tooldata index).-

(saicanon) Sets sai’s

_active_slotto the passed-in pocket number. Tool information is copied from the selected pocket of of the tool table (ie, from sai’s_tools[_active_slot]) to the spindle (aka sai’s_tools[0]). -

(emccanon) Sends an

EMC_TOOL_LOADmessage to Task, which sends it to IO. IO setsemcioStatus.tool.toolInSpindleto the tool number of the tool in the pocket identified byemcioStatus.tool.pocketPrepped(set byTxxxakaSELECT_TOOL()). It then requests that the toolchanger hardware perform a tool change, by setting the HAL piniocontrol.0.tool-changeto True. Later, IO’sread_tool_inputs()will sense that the HAL piniocontrol.0.tool_changedhas been set to True, indicating the toolchanger has completed the tool change. When this happens, it callsload_tool()to update the machine state.-

load_tool()with a nonrandom toolchanger config copies the tool information from the selected pocket to the spindle (pocket 0). -

load_tool()with a random toolchanger config swaps tool information between pocket 0 (the spindle) and the selected pocket, then saves the tool table.

-

-

-

Back in interp,

settings->current_pocketis assigned the new tooldata index fromsettings->selected_pocket(set byTxxx). The relevant numbered parameters (#5400-#5413) are updated with the new tool information from pocket 0 (spindle).

24.3.3. G43/G43.1/G49

Apply tool length offset. G43 uses the TLO of the currently loaded tool, or of a specified tool if the H-word is given in the block. G43.1 gets TLO from axis-words in the block. G49 cancels the TLO (it uses 0 for the offset for all axes).

Handled by Interp::convert_tool_length_offset().

-

It starts by building an

EmcPosecontaining the 9-axis offsets to use. ForG43.1, these tool offsets come from axis words in the current block. ForG43these offsets come from the current tool (the tool in pocket 0), or from the tool specified by the H-word in the block. For G49, the offsets are all 0. -

The offsets are passed to Canon’s

USE_TOOL_LENGTH_OFFSET()function.-

(saicanon) Records the TLO in

_tool_offset. -

(emccanon) Crea un mensaje

EMC_TRAJ_SET_OFFSETque contiene los offsets y lo envía a Task, que copia las compensaciones enemcStatus->task.toolOffsety los envía a Motion a través de un comandoEMCMOT_SET_OFFSET. Motion copia las compensaciones aemcmotStatus->tool_offset, donde se usa para compensar movimientos futuros.

-

-

Back in interp, the offsets are recorded in

settings->tool_offset. The effective pocket is recorded insettings->tool_offset_index, though this value is never used.

24.3.4. G10 L1/L10/L11

Modifies the tool table.

Handled by Interp::convert_setup_tool().

-

Picks the tool number out of the P-word in the block and finds the pocket for that tool:

-

With a nonrandom toolchanger config this is always the pocket number in the toolchanger (even when the tool is in the spindle).

-

Con una configuración de cambiador de herramientas aleatorio, si la herramienta está actualmente cargada utiliza la ranura 0 (ranura 0 significa "el husillo"), y si la herramienta no está cargada, usa el número de ranura en el cambiador de herramientas. (Esta diferencia es importante.)

-

-

Figures out what the new offsets should be.

-

The new tool information (diameter, offsets, angles, and orientation), along with the tool number and pocket number, are passed to the Canon call SET_TOOL_TABLE_ENTRY().

-

(saicanon) Copy the new tool information to the specified pocket (in sai’s internal tool table,

_tools). -

(emccanon) Build an

EMC_TOOL_SET_OFFSETmessage with the new tool information, and send it to Task, which passes it to IO. IO updates the specified pocket in its internal copy of the tool table (emcioStatus.tool.toolTable), and if the specified tool is currently loaded (it is compared toemcioStatus.tool.toolInSpindle) then the new tool information is copied to pocket 0 (the spindle) as well. (FIXME: that’s a buglet, should only be copied on nonrandom machines.) Finally IO saves the new tool table.

-

-

Back in interp, if the modified tool is currently loaded in the spindle, and if the machine is a non-random toolchanger, then the new tool information is copied from the tool’s home pocket to pocket 0 (the spindle) in interp’s copy of the tool table,

settings->tool_table. (This copy is not needed on random tool changer machines because there, tools don’t have a home pocket and instead we just updated the tool in pocket 0 directly.). The relevant numbered parameters (#5400-#5413) are updated from the tool information in the spindle (by copying the information from interp’ssettings->tool_tabletosettings->parameters). (FIXME: this is a buglet, the params should only be updated if it was the current tool that was modified). -

If the modified tool is currently loaded in the spindle, and if the config is for a nonrandom toolchanger, then the new tool information is written to the tool table’s pocket 0 as well, via a second call to SET_TOOL_TABLE_ENTRY(). (This second tool-table update is not needed on random toolchanger machines because there, tools don’t have a home pocket and instead we just updated the tool in pocket 0 directly.)

24.3.5. M61

Set current tool number. This switches LinuxCNC’s internal representation of which tool is in the spindle, without actually moving the toolchanger or swapping any tools.

Handled by Interp::convert_tool_change().

Canon: CHANGE_TOOL_NUMBER()

settings->current_pocket is assigned the tooldata index currently holding the tool specified by the Q-word argument.

24.3.6. G41/G41.1/G42/G42.1

Enable cutter radius compensation (usually called cutter comp).

Handled by Interp::convert_cutter_compensation_on().

No Canon call, cutter comp happens in the interpreter. Uses the tool table in the expected way: if a D-word tool number is supplied it looks up the pocket number of the specified tool number in the table, and if no D-word is supplied it uses pocket 0 (the spindle).

24.3.7. G40

Cancel cutter radius compensation.

Handled by Interp::convert_cutter_compensation_off().

No Canon call, cutter comp happens in the interpreter. Does not use the tool table.

24.4. Internal state variables

This is not an exhaustive list! Tool information is spread through out LinuxCNC.

24.4.1. IO

emcioStatus is of type EMC_IO_STAT

- emcioStatus.tool.pocketPrepped

-

When IO gets the signal from HAL that the toolchanger prep is complete (after a

Txxxcommand), this variable is set to the pocket of the requested tool. When IO gets the signal from HAL that the tool change itself is complete (after anM6command), this variable gets reset to -1. - emcioStatus.tool.toolInSpindle

-

Tool number of the tool currently installed in the spindle. Exported on the HAL pin

iocontrol.0.tool-number(s32). - emcioStatus.tool.toolTable[]

-

An array of

CANON_TOOL_TABLEstructures,CANON_POCKETS_MAXlong. Loaded from the tool table file at startup and maintained there after. Index 0 is the spindle, indexes 1-(CANON_POCKETS_MAX-1) are the pockets in the toolchanger. This is a complete copy of the tool information, maintained separately from Interp’ssettings.tool_table.

24.4.2. interp

settings es de tipo settings, definida como struct setup_struct en src/emc/rs274ngc/interp_internal.hh.

- settings.selected_pocket

-

Tooldata index of the tool most recently selected by

Txxx. - settings.current_pocket

-

Original tooldata index of the tool currently in the spindle. In other words: which tooldata index the tool that’s currently in the spindle was loaded from.

- settings.tool_table[]

-

An array of tool information. The index into the array is the "pocket number" (aka "slot number"). Pocket 0 is the spindle, pockets 1 through (CANON_POCKETS_MAX-1) are the pockets of the toolchanger.

- settings.tool_offset_index

-

Unused. FIXME: Should probably be removed.

- settings.toolchange_flag

-

Interp sets this to true when calling Canon’s CHANGE_TOOL() function. It is checked in

Interp::convert_tool_length_offset()to decide which tooldata index to use for G43 (with no H-word):settings->current_pocketif the tool change is still in progress, tooldata index 0 (the spindle) if the tool change is complete. - settings.random_toolchanger

-

Set from the INI variable

[EMCIO]RANDOM_TOOLCHANGERat startup. Controls various tool table handling logic. (IO also reads this INI variable and changes its behavior based on it. For example, when saving the tool table, random toolchanger save the tool in the spindle (pocket 0), but non-random toolchanger save each tool in its "home pocket".) - settings.tool_offset

-

This is an

EmcPosevariable.-

Used to compute position in various places.

-

Sent to Motion via the

EMCMOT_SET_OFFSETmessage. All motion does with the offsets is export them to the HAL pinsmotion.0.tooloffset.[xyzabcuvw]. FIXME: export these from someplace closer to the tool table (io or interp, probably) and remove the EMCMOT_SET_OFFSET message.

-

- settings.pockets_max

-

Used interchangeably with

CANON_POCKETS_MAX(a #defined constant, set to 1000 as of April 2020). FIXME: This settings variable is not currently useful and should probably be removed. - settings.tool_table

-

This is an array of

CANON_TOOL_TABLEstructures (defined insrc/emc/nml_intf/emctool.h), withCANON_POCKETS_MAXentries. Indexed by "pocket number", aka "slot number". Index 0 is the spindle, indexes 1 to (CANON_POCKETS_MAX-1) are the pockets in the tool changer. On a random toolchanger pocket numbers are meaningful. On a nonrandom toolchanger pockets are meaningless; the pocket numbers in the tool table file are ignored and tools are assigned totool_tableslots sequentially. - settings.tool_change_at_g30

- settings.tool_change_quill_up

- settings.tool_change_with_spindle_on

-

These are set from INI variables in the

[EMCIO]section, and determine how tool changes are performed.

25. Reckoning of joints and axes

25.1. In the status buffer

The status buffer is used by Task and the UIs.

FIXME: axis_mask and axes overspecify the number of axes

-

status.motion.traj.axis_mask -

A bitmask with a "1" for the axes that are present and a "0" for the axes that are not present. X is bit 0 with value 20 = 1 if set, Y is bit 1 with value 21 = 2, Z is bit 2 with value 4, etc. For example, a machine with X and Z axes would have an

axis_maskof 0x5, an XYZ machine would have 0x7, and an XYZB machine would have anaxis_maskof 0x17. -

status.motion.traj.axes(removed) -

This value was removed in LinuxCNC version 2.9. Use

axis_maskinstead. -

status.motion.traj.joints -

A count of the number of joints the machine has. A normal lathe has 2 joints; one driving the X axis and one driving the Z axis. An XYYZ gantry mill has 4 joints: one driving X, one driving one side of the Y, one driving the other side of the Y, and one driving Z. An XYZA mill also has 4 joints.

-

status.motion.axis[EMCMOT_MAX_AXIS] -

An array of

EMCMOT_MAX_AXISaxis structures.axis[n]is valid if(axis_mask & (1 << n))is True. If(axis_mask & (1 << n))is False, thenaxis[n]does not exist on this machine and must be ignored. -

status.motion.joint[EMCMOT_MAX_JOINTS] -

An array of

EMCMOT_MAX_JOINTSjoint structures.joint[0]throughjoint[joints-1]are valid, the others do not exist on this machine and must be ignored.

Things are not this way currently in the joints-axes branch, but deviations from this design are considered bugs. For an example of such a bug, see the treatment of axes in src/emc/ini/initraj.cc:loadTraj(). There are undoubtedly more, and I need your help to find them and fix them.

25.2. In Motion

The Motion controller realtime component first gets the number of joints from the num_joints load-time parameter. This determines how many joints worth of HAL pins are created at startup.

Motion’s number of joints can be changed at runtime using the EMCMOT_SET_NUM_JOINTS command from Task.

The Motion controller always operates on EMCMOT_MAX_AXIS axes. It always creates nine sets of axis.*.* pins.