1. Introduction: Extending the RS274NGC Interpreter by Remapping Codes

1.1. A Definition: Remapping Codes

By remapping codes we mean one of the following:

-

Define the semantics of new - that is, currently unallocated - M- or G-codes

-

Redefine the semantics of a - currently limited - set of existing codes.

1.2. Why would you want to extend the RS274NGC Interpreter?

The set of codes (M,G,T,S,F) currently understood by the RS274NGC interpreter is fixed and cannot be extended by configuration options.

In particular, some of these codes implement a fixed sequence of steps to be executed. While some of these, like M6, can be moderately configured by activating or skipping some of these steps through INI file options, overall the behavior is fairly rigid. So - if your are happy with this situation, then this manual section is not for you.

In many cases, this means that supporting a non out of the box configuration or machine is either cumbersome or impossible, or requires resorting to changes at the C/C+\+ language level. The latter is unpopular for good reasons - changing internals requires in-depth understanding of interpreter internals, and moreover brings its own set of support issues. While it is conceivable that certain patches might make their way into the main LinuxCNC distribution, the result of this approach is a hodge-podge of special-case solutions.

A good example for this deficiency is tool change support in LinuxCNC: While random tool changers are well supported, it is next to impossible to reasonably define a configuration for a manual-tool change machine with, for example, an automatic tool length offset switch being visited after a tool change, and offsets set accordingly. Also, while a patch for a very specific rack tool changer exists, it has not found its way back into the main code base.

However, many of these things may be fixed by using an O-word procedure instead of a built in code - whenever the - insufficient - built in code is to be executed, call the O-word procedure instead. While possible, it is cumbersome - it requires source-editing of NGC programs, replacing all calls to the deficient code by a an O-word procedure call.

In its simplest form, a remapped code isn’t much more than a spontaneous call to an O-word procedure. This happens behind the scenes - the procedure is visible at the configuration level, but not at the NGC program level.

Generally, the behavior of a remapped code may be defined in the following ways:

-

You define a O-word subroutine which implements the desired behavior

-

Alternatively, you may employ a Python function which extends the interpreter’s behavior.

M- and G-codes, and O-words subroutine calls have some fairly different syntax.

O-word procedures, for example, take positional parameters with a specific syntax like so:

o<test> call [1.234] [4.65]

whereas M- or G-codes typically take required or optional word parameters. For instance, G76 (threading) requires the P,Z,I,J and K words, and optionally takes the R,Q,H, E and L words.

So it isn’t simply enough to say whenever you encounter code X, please call procedure Y - at least some checking and conversion of parameters needs to happen. This calls for some glue code between the new code, and its corresponding NGC procedure to execute before passing control to the NGC procedure.

This glue code is impossible to write as an O-word procedure itself, since the RS274NGC language lacks the introspective capabilities and access into interpreter internal data structures to achieve the required effect. Doing the glue code in - again - C/C+\+ would be an inflexible and therefore unsatisfactory solution.

To make a simple situation easy and a complex situation solvable, the glue issue is addressed as follows:

-

For simple situations, a built-in glue procedure (

argspec) covers most common parameter passing requirements. -

For remapping T,M6,M61,S,F there is some standard Python glue which should cover most situations, see Standard Glue.

-

For more complex situations, one can write your own Python glue to implement new behavior.

Embedded Python functions in the Interpreter started out as glue code, but turned out very useful well beyond that. Users familiar with Python will likely find it easier to write remapped codes, glue, O-word procedures, etc. in pure Python, without resorting to the somewhat cumbersome RS274NGC language at all.

Many people are familiar with extending the Python interpreter by C/C++ modules, and this is heavily used in LinuxCNC to access Task, HAL and Interpreter internals from Python scripts. Extending Python basically means: Your Python script executes as it is in the driver seat, and may access non-Python code by importing and using extension modules written in C/C+\+. Examples for this are the LinuxCNC hal, gcode and emc modules.

Embedded Python is a bit different and less commonly known: The main program is written in C/C++ and may use Python like a subroutine. This is powerful extension mechanism and the basis for the scripting extensions found in many successful software packages. Embedded Python code may access C/C+\+ variables and functions through a similar extension module method.

2. Getting started

Defining a code involves the following steps:

-

Pick a code - either use an unallocated code, or redefine an existing code.

-

Decide how parameters are handled.

-

Decide if and how results are handled.

-

Decide about the execution sequence.

2.1. Builtin Remaps

Please note that currently only some existing codes can be redefined, while there are many free codes that may be available for remapping. When developing redefined existing code, it is a good idea to start with an unassigned G- or M- code, so that you can use both an existing behavior as well as a new one. When you’re done, redefine the existing code to use your remapping configuration.

-

The current set of unused M-codes, available for user definition, can be found in the unallocated M-codes section.

-

For G-codes, see the unallocated G-codes list.

-

Existing codes that can be reassigned are listed in the remappable codes section.

There are currently two complete Python-only remaps that are available in stdglue.py:

-

ignore_m6

-

index_lathe_tool_with_wear

These are meant for use with lathe. Lathes don’t use M6 to index the tools, they use the T command.

This remap also adds wear offsets to the tool offset, e.g. T201 would index to tool 2 (with tool 2’s tool offset) and adds wear offset 1. In the tool table, tools numbers above 10000 are wear offsets, e.g. in the tool table, tool 10001 would be wear offset 1.

Here is what you need in the INI to use them:

[RS274NGC] REMAP=T python=index_lathe_tool_with_wear REMAP=M6 python=ignore_m6 [PYTHON] # where to find the Python code: # code specific for this configuration PATH_PREPEND=./ # generic support code - make sure this actually points to Python-stdglue PATH_APPEND=../../nc_files/remap_lib/python-stdglue/ # import the following Python module TOPLEVEL=toplevel.py # the higher the more verbose tracing of the Python plugin LOG_LEVEL = 0

You must also add the required Python file in your configuration folder.

2.2. Picking a code

Note that currently only a few existing codes may be redefined, whereas there are many free codes which might be made available by remapping. When developing a redefined existing code, it might be a good idea to start with an unallocated G- or M-code, so both the existing and new behavior can be exercised. When done, redefine the existing code to use your remapping setup.

2.3. Parameter handling

Let’s assume the new code will be defined by an NGC procedure, and needs some parameters, some of which might be required, others might be optional. We have the following options to feed values to the procedure:

-

Extracting words from the current block and pass them to the procedure as parameters (like

X22.34orP47), -

referring to INI file variables,

-

referring to global variables (like

#2200 = 47.11or#<_global_param> = 315.2).

The first method is preferred for parameters of dynamic nature, like positions. You need to define which words on the current block have any meaning for your new code, and specify how that is passed to the NGC procedure. Any easy way is to use the argspec statement. A custom prolog might provide better error messages.

Using to INI file variables is most useful for referring to setup information for your machine, for instance a fixed position like a tool-length sensor position. The advantage of this method is that the parameters are fixed for your configuration, regardless which NGC file you’re currently executing.

Referring to global variables is always possible, but they are easily overlooked.

Note there’s a limited supply of words which may be used as parameters, so one might need to fall back to the second and third methods if many parameters are needed.

2.4. Handling results

Your new code might succeed or fail, for instance if passed an invalid parameter combination. Or you might choose to just execute the procedure and disregard results, in which case there isn’t much work to do.

Epilog handlers help in processing results of remap procedures - see the reference section.

2.5. Execution sequencing

Executable G-code words are classified into modal groups, which also defines their relative execution behavior.

If a G-code block contains several executable words on a line, these words are executed in a predefined order of execution, not in the order they appear in block.

When you define a new executable code, the interpreter does not yet know where your code fits into this scheme. For this reason, you need to choose an appropriate modal group for your code to execute in.

2.6. An minimal example remapped code

To give you an idea how the pieces fit together, let’s explore a fairly minimal but complete remapped code definition. We choose an unallocated M-code and add the following option to the INI file:

[RS274NGC] REMAP=M400 modalgroup=10 argspec=Pq ngc=myprocedure

In a nutshell, this means:

-

The

M400code takes a required parameterPand an optional parameterQ. Other words in the current block are ignored with respect to theM400code. If thePword is not present, fail execution with an error. -

When an

M400code is encountered, executemyprocedure.ngcalong the other modal group 10 M-codes as per order of execution. -

The value of

P, andQare available in the procedure as local named parameters. The may be referred to as#<P>and#<Q>. The procedure may test whether theQword was present with theEXISTSbuilt in function.

The file myprocedure.ngc is expected to exists in the [DISPLAY]NC_FILES or [RS274NGC]SUBROUTINE_PATH directory.

A detailed discussion of REMAP parameters is found in the reference section below.

3. Configuring Remapping

3.1. The REMAP statement

To remap a code, define it using the REMAP option in RS274NG section of your INI file. Use one REMAP line per remapped code.

The syntax of the REMAP is:

It is an error to omit the <code> parameter.

The options of the REMAP statement are separated by whitespace. The options are keyword-value pairs and currently are:

-

modalgroup=<modal group> -

- G-codes

-

the only currently supported modal group is 1, which is also the default value if no group is given. Group 1 means execute alongside other G-codes.

- M-коды

-

Currently supported modal groups are: 5,6,7,8,9,10. If no modalgroup is give, it defaults to 10 (execute after all other words in the block).

- T,S,F

-

for these the modal group is fixed and any

modalgroup=option is ignored.

-

argspec=<argspec> -

See description of the argspec parameter options. Optional.

-

ngc=<ngc_basename> -

Basename of an O-word subroutine file name. Do not specify an .ngc extension. Searched for in the directories specified in the directory specified in

[DISPLAY]PROGRAM_PREFIX, then in[RS274NGC]SUBROUTINE_PATH. Mutually exclusive withpython=. It is an error to omit bothngc=andpython=. -

python=<Python function name> -

Instead of calling an ngc O-word procedure call a Python function. The function is expected to be defined in the

module_basename.owordmodule. Mutually exclusive withngc=. -

prolog=<Python function name> -

Before executing an ngc procedure, call this Python function. The function is expected to be defined in the

module_basename.remapmodule. Optional. -

epilog=<Python function name> -

After executing an ngc procedure, call this Python function. The function is expected to be defined in the

module_basename.remapmodule. Optional.

The python, prolog and epilog options require the Python Interpreter plugin to be configured, and appropriate Python functions to be defined there so they can be referred to with these options.

The syntax for defining a new code, and redefining an existing code is identical.

3.2. Useful REMAP option combinations

Note that while many combinations of argspec options are possible, not all of them make sense. The following combinations are useful idioms:

-

argspec=<words>ngc=<procname>modalgroup=_<group> -

The recommended way to call an NGC procedure with a standard argspec parameter conversion. Used if argspec is good enough. Note, it is not good enough for remapping the

TxandM6/M61tool change codes. -

prolog=<pythonprolog>ngc=<procname>epilog=<pythonepilog>modalgroup=<group> -

Call a Python prolog function to take any preliminary steps, then call the NGC procedure. When done, call the Python epilog function to do any cleanup or result extraction work which cannot be handled in G-code. The most flexible way of remapping a code to an NGC procedure, since almost all of the Interpreter internal variables, and some internal functions may be accessed from the prolog and epilog handlers. Also, a longer rope to hang yourselves.

-

python=<pythonfunction>modalgroup=<group> -

Directly call to a Python function without any argument conversion. The most powerful way of remapping a code and going straight to Python. Use this if you do not need an NGC procedure, or NGC is just getting in your way.

-

argspec=<words>python=<pythonfunction>modalgroup=<group> -

Convert the argspec words and pass them to a Python function as keyword argument dictionary. Use it when you’re too lazy to investigate words passed on the block yourself.

Note that if all you want to achieve is to call some Python code from G-code, there is the somewhat easier way of calling Python functions like O-word procedures.

3.3. The argspec parameter

The argument specification (keyword argspec) describes required and optional words to be passed to an ngc procedure, as well as optional preconditions for that code to execute.

An argspec consists of 0 or more characters of the class [@A-KMNP-Za-kmnp-z^>]. It can by empty (like argspec=).

An empty argspec, or no argspec argument at all implies the remapped code does not receive any parameters from the block. It will ignore any extra parameters present.

Note that RS274NGC rules still apply - for instance you may use axis words (e.g., X, Y, Z) only in the context of a G-code.

Axis words may also only be used if the axis is enabled. If only XYZ are enabled, ABCUVW will not be available to be used in argspec.

Words F, S and T (short FST) will have the normal functions but will be available as variables in the remapped function. F will set feedrate, S will set spindle RPM, T will trigger the tool prepare function. Words FST should not be used if this behavior is not desired.

Words DEIJKPQR have no predefined function and are recommended for use as argspec parameters.

-

ABCDEFHIJKPQRSTUVWXYZ -

Defines a required word parameter: an uppercase letter specifies that the corresponding word must be present in the current block. The word`s value will be passed as a local named parameter with a corresponding name. If the

@character is present in the argspec, it will be passed as positional parameter, see below. -

abcdefhijkpqrstuvwxyz -

Defines an optional word parameter: a lowercase letter specifies that the corresponding word may be present in the current block. If the word is present, the word’s value will be passed as a local named parameter. If the

@character is present in the argspec, it will be passed as positional parameter, see below. -

@ -

The

@(at-sign) tells argspec to pass words as positional parameters, in the order defined following the@option. Note that when using positional parameter passing, a procedure cannot tell whether a word was present or not, see example below.

|

Tip

|

this helps with packaging existing NGC procedures as remapped codes. Existing procedures do expect positional parameters. With the @ option, you can avoid rewriting them to refer to local named parameters. |

-

^ -

The

^(caret) character specifies that the current spindle speed must be greater than zero (spindle running), otherwise the code fails with an appropriate error message. -

> -

The

>(greater-than) character specifies that the current feed must be greater than zero, otherwise the code fails with an appropriate error message. -

n -

The

n(greater-than) character specifies to pass the current line number in the `n`local named parameter.

By default, parameters are passed as local named parameter to an NGC procedure. These local parameters appear as already set when the procedure starts executing, which is different from existing semantics (local variables start out with value 0.0 and need to be explicitly assigned a value).

Optional word parameters may be tested for presence by the EXISTS(#<word>) idiom.

Assume the code is defined as

REMAP=M400 modalgroup=10 argspec=Pq ngc=m400

and m400.ngc looks as follows:

o<m400> sub (P is required since it is uppercase in the argspec) (debug, P word=#<P>) (the q argspec is optional since its lowercase in the argspec. Use as follows:) o100 if [EXISTS[#<q>]] (debug, Q word set: #<q>) o100 endif o<m400> endsub M2

-

Executing

M400will fail with the messageuser-defined M400: missing: P. -

Executing

M400 P123will displayP word=123.000000. -

Executing

M400 P123 Q456will displayP word=123.000000andQ word set: 456.000000.

Assume the code is defined as

REMAP=M410 modalgroup=10 argspec=@PQr ngc=m410

and m410.ngc looks as follows:

o<m410> sub (debug, [1]=#1 [2]=#2 [3]=#3) o<m410> endsub M2

-

Executing

M410 P10will displaym410.ngc: [1]=10.000000 [2]=0.000000. -

Executing

M410 P10 Q20will displaym410.ngc: [1]=10.000000 [2]=20.000000.

|

Note

|

you lose the capability to distinguish more than one optional parameter word, and you cannot tell whether an optional parameter was present but had the value 0, or was not present at all. |

It’s possible to define new codes without any NGC procedure. Here’s a simple first example, a more complex one can be found in the next section.

Assume the code is defined as

REMAP=G88.6 modalgroup=1 argspec=XYZp python=g886

This instructs the interpreter to execute the Python function g886 in the module_basename.remap module, which might look like so:

from interpreter import INTERP_OK from emccanon import MESSAGE def g886(self, **words): for key in words: MESSAGE("word '%s' = %f" % (key, words[key])) if words.has_key('p'): MESSAGE("the P word was present") MESSAGE("comment on this line: '%s'" % (self.blocks[self.remap_level].comment)) return INTERP_OK

Try this with out with: g88.6 x1 y2 z3 g88.6 x1 y2 z3 p33 (a comment here)

You’ll notice the gradual introduction of the embedded Python environment - see here for details. Note that with Python remapping functions, it make no sense to have Python prolog or epilog functions since it is executing a Python function in the first place.

The interpreter and emccanon modules expose most of the Interpreter and some Canon internals, so many things which so far required coding in C/C+\+ can be now be done in Python.

The following example is based on the nc_files/involute.py script - but canned as a G-code with some parameter extraction and checking. It also demonstrates calling the interpreter recursively (see self.execute()).

Assuming a definition like so (NB: this does not use argspec):

REMAP=G88.1 modalgroup=1 py=involute

The involute function in python/remap.py listed below does all word extraction from the current block directly. Note that interpreter errors can be translated to Python exceptions. Remember this is readahead time - execution time errors cannot be trapped this way.

import sys import traceback from math import sin,cos from interpreter import * from emccanon import MESSAGE from util import lineno, call_pydevd # raises InterpreterException if execute() or read() fails throw_exceptions = 1 def involute(self, **words): """ remap function with raw access to Interpreter internals """ if self.debugmask & 0x20000000: call_pydevd() # USER2 debug flag if equal(self.feed_rate,0.0): return "feedrate > 0 required" if equal(self.speed[0], 0.0): return "spindle speed > 0 required" plunge = 0.1 # if Z word was given, plunge - with reduced feed # inspect controlling block for relevant words c = self.blocks[self.remap_level] x0 = c.x_number if c.x_flag else 0 y0 = c.y_number if c.y_flag else 0 a = c.p_number if c.p_flag else 10 old_z = self.current_z if self.debugmask & 0x10000000: print("x0=%f y0=%f a=%f old_z=%f" % (x0,y0,a,old_z)) try: #self.execute("G3456") # would raise InterpreterException self.execute("G21",lineno()) self.execute("G64 P0.001",lineno()) self.execute("G0 X%f Y%f" % (x0,y0),lineno()) if c.z_flag: feed = self.feed_rate self.execute("F%f G1 Z%f" % (feed * plunge, c.z_number),lineno()) self.execute("F%f" % (feed),lineno()) for i in range(100): t = i/10. x = x0 + a * (cos(t) + t * sin(t)) y = y0 + a * (sin(t) - t * cos(t)) self.execute("G1 X%f Y%f" % (x,y),lineno()) if c.z_flag: # retract to starting height self.execute("G0 Z%f" % (old_z),lineno()) except InterpreterException,e: msg = "%d: '%s' - %s" % (e.line_number,e.line_text, e.error_message) return msg return INTERP_OK

The examples described so far can be found in configs/sim/axis/remap/getting-started with complete working configurations.

4. Upgrading an existing configuration for remapping

The minimal prerequisites for using REMAP statements are as follows:

-

The Python plug in must be activated by specifying a

[PYTHON]TOPLEVEL=<path-to-toplevel-script>in the INI file. -

The toplevel script needs to import the

remapmodule, which can be initially empty, but the import needs to be in place. -

The Python interpreter needs to find the remap.py module above, so the path to the directory where your Python modules live needs to be added with

[PYTHON]PATH_APPEND=<path-to-your-local-Python-directory> -

Recommended: import the

stdgluehandlers in theremapmodule. In this case Python also needs to findstdglue.py- we just copy it from the distribution so you can make local changes as needed. Depending on your installation the path tostdglue.pymight vary.

Assuming your configuration lives under /home/user/xxx and the INI file is /home/user/xxx/xxx.ini, execute the following commands.

$ cd /home/user/xxx $ mkdir python $ cd python $ cp /usr/share/linuxcnc/ncfiles/remap_lib/python-stdglue/stdglue.py . $ echo 'from stdglue import *' >remap.py $ echo 'import remap' >toplevel.py

Now edit ``/home/user/``xxx``/``xxx``.ini`` and add the following:

[PYTHON] TOPLEVEL=/home/user/xxx/python/toplevel.py PATH_APPEND=/home/user/xxx/python

Now verify that LinuxCNC comes up with no error messages - from a terminal window execute:

$ cd /home/user/xxx

$ linuxcnc xxx.ini5. Remapping tool change-related codes: T, M6, M61

5.1. Обзор

If you are unfamiliar with LinuxCNC internals, first read the How tool change currently works section (dire but necessary).

Note than when remapping an existing code, we completely disable this codes' built-in functionality of the interpreter.

So our remapped code will need to do a bit more than just generating some commands to move the machine as we like - it will also need to replicate those steps from this sequence which are needed to keep the interpreter and task happy.

However, this does not affect the processing of tool change-related commands in task and iocontrol. This means when we execute step 6b this will still cause iocontrol to do its thing.

Decisions, decisions:

-

Do we want to use an O-word procedure or do it all in Python code?

-

Is the

iocontrolHAL sequence (tool-prepare/tool-prepared and tool-change/tool-changed pins) good enough or do we need a different kind of HAL interaction for our tool changer (for example: more HAL pins involved with a different interaction sequence)?

Depending on the answer, we have four different scenarios:

-

When using an O-word procedure, we need prolog and epilog functions.

-

If using all Python code and no O-word procedure, a Python function is enough.

-

When using the

iocontrolpins, our O-word procedure or Python code will contain mostly moves. -

When we need a more complex interaction than offered by

iocontrol, we need to completely define our own interaction, usingmotion.digital*andmotion.analog*pins, and essentially ignore theiocontrolpins by looping them.

|

Note

|

If you hate O-word procedures and love Python, you are free to do it all in Python, in which case you would just have a python=<function> spec in the REMAP statement. But assuming most folks would be interested in using O-word procedures because they are more familiar with that, we’ll do that as the first example. |

So the overall approach for our first example will be:

-

We’d like to do as much as possible with G-code in an O-word procedure for flexibility. That includes all HAL interaction which would normally be handled by

iocontrol- because we rather would want to do clever things with moves, probes, HAL pin I/O and so forth. -

We’ll try to minimize Python code to the extent needed to keep the interpreter happy, and cause

taskto actually do anything. That will go into theprologandepilogPython functions.

5.2. Understanding the role of iocontrol with remapped tool change codes

iocontrol provides two HAL interaction sequences we might or might not use:

-

When the NML message queued by a SELECT_TOOL() canon command is executed, this triggers the "raise tool-prepare and wait for tool-prepared to become high" HAL sequence in

iocontrol, besides setting the XXXX pins -

When the NML message queued by the CHANGE_TOOL() canon command is executed, this triggers the "raise tool-change and wait for tool-changed to become high" HAL sequence in

iocontrol, besides setting the XXXX pins

What you need to decide is whether the existing iocontrol HAL sequences are sufficient to drive your changer. Maybe you need a different interaction sequence - for instance more HAL pins, or maybe a more complex interaction. Depending on the answer, we might continue to use the existing iocontrol HAL sequences, or define our own ones.

For the sake of documentation, we’ll disable these iocontrol sequences, and roll our own - the result will look and feel like the existing interaction, but now we have complete control over them because they are executed in our own O-word procedure.

So what we’ll do is use some motion.digital-* and motion.analog-* pins, and the associated M62 .. M68 commands to do our own HAL interaction in our O-word procedure, and those will effectively replace the iocontrol tool-prepare/tool-prepared and tool-change/tool-changed sequences. So we’ll define our pins replacing existing iocontrol pins functionally, and go ahead and make the iocontrol interactions a loop. We’ll use the following correspondence in our example:

iocontrol pin correspondence in the examples

iocontrol.0 pin |

motion pin |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Let us assume you want to redefine the M6 command, and replace it by an O-word procedure, but other than that things should continue to work.

So what our O-word procedure would do is to replace the steps outlined here. Looking through these steps you’ll find that NGC code can be used for most of them, but not all. So the stuff NGC can’t handle will be done in Python prolog and epilog functions.

5.3. Specifying the M6 replacement

To convey the idea, we just replace the built in M6 semantics with our own. Once that works, you may go ahead and place any actions you see fit into the O-word procedure.

Going through the steps, we find:

-

check for T command already executed - execute in Python prolog

-

check for cutter compensation being active - execute in Python prolog

-

stop the spindle if needed - can be done in NGC

-

quill up - can be done in NGC

-

if TOOL_CHANGE_AT_G30 was set:

-

move the A, B and C indexers if applicable - can be done in NGC

-

generate rapid move to the G30 position - can be done in NGC

-

-

send a CHANGE_TOOL Canon command to

task- execute in Python epilog -

set the numbered parameters 5400-5413 according to the new tool - execute in Python epilog

-

signal to

taskto stop calling the interpreter for readahead until tool change complete - execute in Python epilog

So we need a prolog, and an epilog. Lets assume our INI file incantation of the M6 remap looks as follows:

REMAP=M6 modalgroup=6 prolog=change_prolog ngc=change epilog=change_epilogSo the prolog covering steps 1 and 2 would look like so - we decide to pass a few variables to the remap procedure which can be inspected and changed there, or used in a message. Those are: tool_in_spindle, selected_tool (tool numbers) and their respective tooldata indices current_pocket and selected_pocket:

|

Note

|

Устаревшие имена selected_pocket и current_pocket на самом деле ссылаются на последовательный индекс данных инструмента для элементов инструмента, загруженных из таблицы инструментов ([EMCIO]TOOL_TABLE) или через базу данных инструментов ([EMCIO]DB_PROGRAM). |

def change_prolog(self, **words): try: if self.selected_pocket < 0: return "M6: no tool prepared" if self.cutter_comp_side: return "Cannot change tools with cutter radius compensation on" self.params["tool_in_spindle"] = self.current_tool self.params["selected_tool"] = self.selected_tool self.params["current_pocket"] = self.current_pocket self.params["selected_pocket"] = self.selected_pocket return INTERP_OK except Exception as e: return "M6/change_prolog: {}".format(e)

You will find that most prolog functions look very similar:

-

First test that all preconditions for executing the code hold, then

-

prepare the environment - inject variables and/or do any preparatory processing steps which cannot easily be done in NGC code;

-

then hand off to the NGC procedure by returning INTERP_OK.

Our first iteration of the O-word procedure is unexciting - just verify we got parameters right, and signal success by returning a positive value; steps 3-5 would eventually be covered here (see here for the variables referring to INI file settings):

O<change> sub (debug, change: current_tool=#<current_tool>) (debug, change: selected_pocket=#<selected_pocket>) ; ; insert any G-code which you see fit here, e.g.: ; G0 #<_ini[setup]tc_x> #<_ini[setup]tc_y> #<_ini[setup]tc_z> ; O<change> endsub [1] m2

Assuming success of change.ngc, we need to mop up steps 6-8:

def change_epilog(self, **words): try: if self.return_value > 0.0: # commit change self.selected_pocket = int(self.params["selected_pocket"]) emccanon.CHANGE_TOOL(self.selected_pocket) # cause a sync() self.tool_change_flag = True self.set_tool_parameters() return INTERP_OK else: return "M6 aborted (return code %.1f)" % (self.return_value) except Exception, e: return "M6/change_epilog: %s" % (e)

This replacement M6 is compatible with the built in code, except steps 3-5 need to be filled in with your NGC code.

Again, most epilogs have a common scheme:

-

First, determine whether things went right in the remap procedure,

-

then do any commit and cleanup actions which can’t be done in NGC code.

5.4. Configuring iocontrol with a remapped M6

Note that the sequence of operations has changed: we do everything required in the O-word procedure - including any HAL pin setting/reading to get a changer going, and to acknowledge a tool change - likely with motion.digital-* and motion-analog-* IO pins. When we finally execute the CHANGE_TOOL() command, all movements and HAL interactions are already completed.

Normally only now iocontrol would do its thing as outlined here. However, we don’t need the HAL pin wiggling anymore - all iocontrol is left to do is to accept we’re done with prepare and change.

This means that the corresponding iocontrol pins have no function any more. Therefore, we configure iocontrol to immediately acknowledge a change by configuring like so:

# loop change signals when remapping M6 net tool-change-loop iocontrol.0.tool-change iocontrol.0.tool-changed

If you for some reason want to remap Tx (prepare), the corresponding iocontrol pins need to be looped as well.

5.5. Writing the change and prepare O-word procedures

The standard prologs and epilogs found in ncfiles/remap_lib/python-stdglue/stdglue.py pass a few exposed parameters to the remap procedure.

An exposed parameter is a named local variable visible in a remap procedure which corresponds to interpreter-internal variable, which is relevant for the current remap. Exposed parameters are set up in the respective prolog, and inspected in the epilog. They can be changed in the remap procedure and the change will be picked up in the epilog. The exposed parameters for remappable built in codes are:

-

T(prepare_prolog):#<tool>,#<pocket> -

M6(change_prolog):#<tool_in_spindle>,#<selected_tool>,#<current_pocket>,#<selected_pocket> -

M61(settool_prolog):#<tool>,#<pocket> -

S(setspeed_prolog):#<speed> -

F(setfeed_prolog):#<feed>

If you have specific needs for extra parameters to be made visible, that can simply be added to the prolog - practically all of the interpreter internals are visible to Python.

5.6. Making minimal changes to the built in codes, including M6

Remember that normally remapping a code completely disables all internal processing for that code.

However, in some situations it might be sufficient to add a few codes around the existing M6 built in implementation, like a tool length probe, but other than that retain the behavior of the built in M6.

Since this might be a common scenario, the built in behavior of remapped codes has been made available within the remap procedure. The interpreter detects that you are referring to a remapped code within the procedure which is supposed to redefine its behavior. In this case, the built in behavior is used - this currently is enabled for the set: M6, M61,T, S, F. Note that otherwise referring to a code within its own remap procedure would be a error - a remapping recursion.

Slightly twisting a built in would look like so (in the case of M6):

REMAP=M6 modalgroup=6 ngc=mychangeo<mychange> sub M6 (use built in M6 behavior) (.. move to tool length switch, probe and set tool length..) o<mychange> endsub m2

|

Caution

|

When redefining a built-in code, do not specify any leading zeroes in G- or M-codes - for example, say REMAP=M1 .., not REMAP=M01 .... |

See the configs/sim/axis/remap/extend-builtins directory for a complete configuration, which is the recommended starting point for own work when extending built in codes.

5.7. Specifying the T (prepare) replacement

If you’re confident with the default implementation, you wouldn’t need to do this. But remapping is also a way to work around deficiencies in the current implementation, for instance to not block until the "tool-prepared" pin is set.

What you could do, for instance, is:

- In a remapped T, just set the equivalent of the tool-prepare pin, but not wait for tool-prepared here.

- In the corresponding remapped M6, wait for the tool-prepared at the very beginning of the O-word procedure.

Again, the iocontrol tool-prepare/tool-prepared pins would be unused and replaced by motion.* pins, so those would pins must be looped:

# loop prepare signals when remapping T net tool-prep-loop iocontrol.0.tool-prepare iocontrol.0.tool-prepared

So, here’s the setup for a remapped T:

REMAP=T prolog=prepare_prolog epilog=prepare_epilog ngc=preparedef prepare_prolog(self,**words): try: cblock = self.blocks[self.remap_level] if not cblock.t_flag: return "T requires a tool number" tool = cblock.t_number if tool: (status, pocket) = self.find_tool_pocket(tool) if status != INTERP_OK: return "T%d: pocket not found" % (tool) else: pocket = -1 # this is a T0 - tool unload # these variables will be visible in the ngc O-word sub # as #<tool> and #<pocket> local variables, and can be # modified there - the epilog will retrieve the changed # values self.params["tool"] = tool self.params["pocket"] = pocket return INTERP_OK except Exception, e: return "T%d/prepare_prolog: %s" % (int(words['t']), e)

The minimal ngc prepare procedure again looks like so:

o<prepare> sub ; returning a positive value to commit: o<prepare> endsub [1] m2

And the epilog:

def prepare_epilog(self, **words): try: if self.return_value > 0: self.selected_tool = int(self.params["tool"]) self.selected_pocket = int(self.params["pocket"]) emccanon.SELECT_TOOL(self.selected_tool) return INTERP_OK else: return "T%d: aborted (return code %.1f)" % (int(self.params["tool"]),self.return_value) except Exception, e: return "T%d/prepare_epilog: %s" % (tool,e)

The functions prepare_prolog and prepare_epilog are part of the standard glue provided by nc_files/remap_lib/python-stdglue/stdglue.py. This module is intended to cover most standard remapping situations in a common way.

5.8. Error handling: dealing with abort

The built in tool change procedure has some precautions for dealing with a program abort, e.g., by hitting escape in AXIS during a change. Your remapped function has none of this, therefore some explicit cleanup might be needed if a remapped code is aborted. In particular, a remap procedure might establish modal settings which are undesirable to have active after an abort. For instance, if your remap procedure has motion codes (G0,G1,G38..) and the remap is aborted, then the last modal code will remain active. However, you very likely want to have any modal motion canceled when the remap is aborted.

The way to do this is by using the [RS274NGC]ON_ABORT_COMMAND feature. This INI option specifies a O-word procedure call which is executed if task for some reason aborts program execution. on_abort receives a single parameter indicating the cause for calling the abort procedure, which might be used for conditional cleanup.

The reasons are defined in nml_intf/emc.hh

EMC_ABORT_TASK_EXEC_ERROR = 1, EMC_ABORT_AUX_ESTOP = 2, EMC_ABORT_MOTION_OR_IO_RCS_ERROR = 3, EMC_ABORT_TASK_STATE_OFF = 4, EMC_ABORT_TASK_STATE_ESTOP_RESET = 5, EMC_ABORT_TASK_STATE_ESTOP = 6, EMC_ABORT_TASK_STATE_NOT_ON = 7, EMC_ABORT_TASK_ABORT = 8, EMC_ABORT_INTERPRETER_ERROR = 9, // interpreter failed during readahead EMC_ABORT_INTERPRETER_ERROR_MDI = 10, // interpreter failed during MDI execution EMC_ABORT_USER = 100 // user-defined abort codes start here

[RS274NGC] ON_ABORT_COMMAND=O <on_abort> call

The suggested on_abort procedure would look like so (adapt to your needs):

o<on_abort> sub G54 (origin offsets are set to the default) G17 (select XY plane) G90 (absolute) G94 (feed mode: units/minute) M48 (set feed and speed overrides) G40 (cutter compensation off) M5 (spindle off) G80 (cancel modal motion) M9 (mist and coolant off) o100 if [#1 eq 5] (machine on) o100 elseif [#1 eq 6] (machine off) o100 elseif [#1 eq 7] (estopped) o100 elseif [#1 eq 8] (msg, abort pressed) o100 else (DEBUG, error parameter is [#1]) o100 endif o<on_abort> endsub m2

|

Caution

|

Never use an M2 in a O-word subroutine, including this one. It will cause hard-to-find errors. For instance, using an M2 in a subroutine will not end the subroutine properly and will leave the subroutine NGC file open, not your main program. |

Make sure on_abort.ngc is along the interpreter search path (recommended location: SUBROUTINE_PATH so as not to clutter your NC_FILES directory with internal procedures).

Statements in that procedure typically would assure that post-abort any state has been cleaned up, like HAL pins properly reset. For an example, see configs/sim/axis/remap/rack-toolchange.

Note that terminating a remapped code by returning INTERP_ERROR from the epilog (see previous section) will also cause the on_abort procedure to be called.

5.9. Error handling: failing a remapped code NGC procedure

If you determine in your handler procedure that some error condition occurred, do not use M2 to end your handler - see above:

If displaying an operator error message and stopping the current program is good enough, use the (abort, `__<message>__)` feature to terminate the handler with an error message. Note that you can substitute numbered, named, INI and HAL parameters in the text like in this example (see also tests/interp/abort-hot-comment/test.ngc):

o100 if [..] (some error condition) (abort, Bad Things! p42=#42 q=#<q> INI=#<_ini[a]x> pin=#<_hal[component.pin]) o100 endif

|

Note

|

INI and HAL variable expansion is optional and can be disabled in the INI file |

If more fine grained recovery action is needed, use the idiom laid out in the previous example:

-

Define an epilog function, even if it is just to signal an error condition,

-

pass a negative value from the handler to signal the error,

-

inspect the return value in the epilog function,

-

take any recovery action needed,

-

return the error message string from the handler, which will set the interpreter error message and abort the program (pretty much like

abort, message=).

This error message will be displayed in the UI, and returning INTERP_ERROR will cause this error handled like any other runtime error.

Note that both (abort, <msg> ) and returning INTERP_ERROR from an epilog will cause any ON_ABORT handler to be called as well if defined (see previous section).

6. Remapping other existing codes:

6.1. Automatic gear selection be remapping S (set spindle speed)

A potential use for a remapped S code would be automatic gear selection depending on speed. In the remap procedure one would test for the desired speed attainable given the current gear setting, and change gears appropriately if not.

6.2. Adjusting the behavior of M0, M1

A use case for remapping M0/M1 would be to customize the behavior of the existing code. For instance, it could be desirable to turn off the spindle, mist and flood during an M0 or M1 program pause, and turn these settings back on when the program is resumed.

For a complete example doing just that, see configs/sim/axis/remap/extend-builtins/, which adapts M1 as laid out above.

6.3. Adjusting the behavior of M7, M8, M9

An example for remapping the built in behavior of M7/M8/M9 is the option to pass optional arguments like a P word for more complex coolant control (eg through tool vs external coolant flow).

See configs/sim/axis/remap/extend-builtins/, for an example of such an extension of the built in behavior for M7,M8 and M9.

7. Creating new G-code cycles

A G-code cycle as used here is meant to behave as follows:

-

On first invocation, the associated words are collected and the G-code cycle is executed.

-

If subsequent lines just continue parameter words applicable to this code, but no new G-code, the previous G-code is re-executed with the parameters changed accordingly.

An example: Assume you have G84.3 defined as remapped G-code cycle with the following INI segment (see here for a detailed description of cycle_prolog and cycle_epilog):

[RS274NGC] # A cycle with an O-word procedure: G84.3 <X- Y- Z- Q- P-> REMAP=G84.3 argspec=xyzabcuvwpr prolog=cycle_prolog ngc=g843 epilog=cycle_epilog modalgroup=1

Executing the following lines:

g17 (1) g84.3 x1 y2 z3 r1 (2) x3 y4 p2 (3) x6 y7 z5 (4) G80

causes the following (note R is sticky, and Z is sticky since the plane is XY):

-

g843.ngcis called with words x=1, y=2, z=3, r=1 -

g843.ngcis called with words x=3, y=4, z=3, p=2, r=1 -

g843.ngcis called with words x=6, y=7, z=3, r=1 -

The

G84.3cycle is canceled.

Besides creating new cycles, this provides an easy method for repackaging existing G-codes which do not behave as cycles. For instance, the G33.1 Rigid Tapping code does not behave as a cycle. With such a wrapper, a new code can be easily created which uses G33.1 but behaves as a cycle.

See configs/sim/axis/remap/cycle for a complete example of this feature. It contains two cycles, one with an NGC procedure like above, and a cycle example using just Python.

8. Configuring Embedded Python

The Python plugin serves both the interpreter, and task if so configured, and hence has its own section PYTHON in the INI file.

8.1. Python plugin : INI file configuration

-

[PYTHON] -

-

TOPLEVEL =<filename> -

Filename of the initial Python script to execute on startup. This script is responsible for setting up the package name structure, see below.

-

PATH_PREPEND =<directory> -

Prepend this directory to

PYTHON_PATH. A repeating group. -

PATH_APPEND =<directory> -

Append this directory to

PYTHON_PATH. A repeating group. -

LOG_LEVEL =<integer> -

Log level of plugin-related actions. Increase this if you suspect problems. Can be very verbose.

-

RELOAD_ON_CHANGE =[0|1] -

Reload the TOPLEVEL script if the file was changed. Handy for debugging but currently incurs some runtime overhead. Turn this off for production configurations.

-

8.2. Executing Python statements from the interpreter

For ad-hoc execution of commands the Python hot comment has been added. Python output by default goes to stdout, so you need to start LinuxCNC from a terminal window to see results. Example for the MDI window:

;py,print(2*3)Note that the interpreter instance is available here as this, so you could also run:

;py,print(this.tool_table[0].toolno)Here is an approach to use an O-word subroutine to read a preference file entry and add it as a G-code parameter.

(filename myofile.ngc) o<myofile> sub ;py,from interpreter import * ;py,import os ;py,from qtvcp.lib.preferences import Access ; find and print the preference file path ;py,CONFPATH = os.environ.get('CONFIG_DIR', '/dev/null') ; adjust for your preference file name ;py,PREFFILE = os.path.join(CONFPATH,'qtdragon.pref') ;py,print(PREFFILE) ; get an preference instance ;py,Pref = Access(PREFFILE) ; load a preference and print it ;py,this.params['toolToLoad']=Pref.getpref('Tool to load', 0, int,'CUSTOM_FORM_ENTRIES') ;py,print('Tool to load->:',this.params['toolToLoad']) ; return the value o<myofile> endsub [#<toolToLoad>] M2

9. Programming Embedded Python in the RS274NGC Interpreter

9.1. The Python plugin namespace

The namespace is expected to be laid out as follows:

-

oword -

Any callables in this module are candidates for Python O-word procedures. Note that the Python

owordmodule is checked before testing for a NGC procedure with the same name - in effect names inowordwill hide NGC files of the same basename. -

remap -

Python callables referenced in an argspec

prolog,epilogorpythonoption are expected to be found here. -

namedparams -

Python functions in this module extend or redefine the namespace of predefined named parameters, see adding predefined parameters.

9.2. The Interpreter as seen from Python

The interpreter is an existing C++ class (Interp) defined in src/emc/rs274ngc. Conceptually all oword.<function> and remap.<function> Python calls are methods of this Interp class, although there is no explicit Python definition of this class (it is a Boost.Python wrapper instance) and hence receive the as the first parameter self which can be used to access internals.

9.3. The Interpreter __init__ and __delete__ functions

If the TOPLEVEL module defines a function __init__, it will be called once the interpreter is fully configured (INI file read, and state synchronized with the world model).

If the TOPLEVEL module defines a function __delete__, it will be called once before the interpreter is shutdown and after the persistent parameters have been saved to the PARAMETER_FILE.

Note_ at this time, the __delete__ handler does not work for interpreter instances created by importing the gcode module. If you need an equivalent functionality there (which is quite unlikely), please consider the Python atexit module.

# this would be defined in the TOPLEVEL module def __init__(self): # add any one-time initialization here if self.task: # this is the milltask instance of interp pass else: # this is a non-milltask instance of interp pass def __delete__(self): # add any cleanup/state saving actions here if self.task: # as above pass else: pass

This function may be used to initialize any Python-side attributes which might be needed later, for instance in remap or O-word functions, and save or restore state beyond what PARAMETER_FILE provides.

If there are setup or cleanup actions which are to happen only in the milltask Interpreter instance (as opposed to the interpreter instance which sits in the gcode Python module and serves preview/progress display purposes but nothing else), this can be tested for by evaluating self.task.

An example use of __init__ and __delete__ can be found in configs/sim/axis/remap/cycle/python/toplevel.py initialising attributes, needed to handle cycles in ncfiles/remap_lib/python-stdglue/stdglue.py (and imported into configs/sim/axis/remap/cycle/python/remap.py).

9.4. Calling conventions: NGC to Python

Python code is called from NGC in the following situations:

-

during normal program execution:

-

when an O-word call like

O<proc> callis executed and the nameoword.procis defined and callable -

when a comment like

;py,<Python statement>is executed. -

during execution of a remapped code: any

prolog=,python=andepilog=handlers.

-

Arguments:

-

self -

The interpreter instance.

-

*args -

The list of actual positional parameters. Since the number of actual parameters may vary, it is best to use this style of declaration:

# this would be defined in the oword module def mysub(self, *args): print("number of parameters passed:", len(args)) for a in args: print(a)

Just as NGC procedures may return values, so do O-word Python subroutines. They are expected to either return

-

no value (no

returnstatement or the valueNone), -

a float or int value,

-

a string, this means this is an error message, abort the program. Works like

(abort, msg).

Any other return value type will raise a Python exception.

In a calling NGC environment, the following predefined named parameters are available:

-

#<value> -

Value returned by the last procedure called. Initialized to 0.0 on startup. Exposed in Interp as

self.return_value(float). -

#<value_returned> -

Indicates the last procedure called did

returnorendsubwith an explicit value. 1.0 if true. Set to 0.0 on eachcall. Exposed in Interp wasself.value_returned(int).

See also tests/interp/value-returned for an example.

Arguments are:

-

self -

The interpreter instance.

-

words -

Keyword parameter dictionary. If an argspec was present, words are collected from the current block accordingly and passed in the dictionary for convenience (the words could as well be retrieved directly from the calling block, but this requires more knowledge of interpreter internals). If no argspec was passed, or only optional values were specified and none of these was present in the calling block, this dict is empty. Word names are converted to lowercase.

Example call:

def minimal_prolog(self, **words): # in remap module print(len(words)," words passed") for w in words: print("%s: %s" % (w, words[w])) if words['p'] < 78: # NB: could raise an exception if p were optional return "failing miserably" return INTERP_OK

Return values:

-

INTERP_OK -

Return this on success. You need to import this from

interpreter. - a message text

-

Returning a string from a handler means this is an error message, abort the program. Works like

(abort,<msg>).

Arguments are:

-

self -

The interpreter instance.

-

words -

Keyword parameter dictionary. The same kwargs dictionary as prologs and epilogs (see above).

The minimum python= function example:

def useless(self, **words): # in remap module return INTERP_OK

Return values:

-

INTERP_OK -

Return this on success

- a message text

-

Returning a string from a handler means this is an error message, abort the program. Works like

(abort,<msg>).

If the handler needs to execute a queuebuster operation (tool change, probe, HAL pin reading) then it is supposed to suspend execution with the following statement:

-

yield INTERP_EXECUTE_FINISH -

This signals

taskto stop read ahead, execute all queued operations, execute the queue-buster operation, synchronize interpreter state with machine state, and then signal the interpreter to continue. At this point the function is resumed at the statement following theyield ..statement.

Queue busters interrupt a procedure at the point where such an operation is called, hence the procedure needs to be restarted after the interpreter synch(). When this happens the procedure needs to know if it is restarted, and where to continue. The Python generator method is used to deal with procedure restart.

This demonstrates call continuation with a single point-of-restart:

def read_pin(self,*args): # wait 5secs for digital-input 00 to go high emccanon.WAIT(0,1,2,5.0) # cede control after executing the queue buster: yield INTERP_EXECUTE_FINISH # post-sync() execution resumes here: pin_status = emccanon.GET_EXTERNAL_DIGITAL_INPUT(0,0); print("pin status=",pin_status)

|

Warning

|

The yield feature is fragile. The following restrictions apply to the usage of yield INTERP_EXECUTE_FINISH: |

-

Python code executing a yield INTERP_EXECUTE_FINISH must be part of a remap procedure. Yield does not work in a Python oword procedure.

-

A Python remap subroutine containing yield INTERP_EXECUTE_FINISH statement may not return a value, as with normal Python yield statements.

-

Code following a yield may not recursively call the interpreter, like with

self.execute("<mdi command>"). This is an architectural restriction of the interpreter and is not fixable without a major redesign.

9.5. Calling conventions: Python to NGC

NGC code is executed from Python when

-

the method

self.execute(<NGC code>[,<line number>])is executed, or -

during execution of a remapped code, if a

prolog=function is defined, the NGC procedure given inngc=is executed immediately thereafter.

The prolog handler does not call the handler, but it prepares its call environment, for instance by setting up predefined local parameters.

Conceptually a prolog and an epilog execute at the same call level like the O-word procedure, that is after the subroutine call is set up, and before the subroutine endsub or return.

This means that any local variable created in a prolog will be a local variable in the O-word procedure, and any local variables created in the O-word procedure are still accessible when the epilog executes.

The self.params array handles reading and setting numbered and named parameters. If a named parameter begins with _ (underscore), it is assumed to be a global parameter; if not, it is local to the calling procedure. Also, numbered parameters in the range 1..30 are treated like local variables; their original values are restored on return/endsub from an O-word procedure.

Here is an example remapped code demonstrating insertion and extraction of parameters into/from the O-word procedure:

REMAP=m300 prolog=insert_param ngc=testparam epilog=retrieve_param modalgroup=10def insert_param(self, **words): # in the remap module print("insert_param call level=",self.call_level) self.params["myname"] = 123 self.params[1] = 345 self.params[2] = 678 return INTERP_OK def retrieve_param(self, **words): print("retrieve_param call level=",self.call_level) print("#1=", self.params[1]) print("#2=", self.params[2]) try: print("result=", self.params["result"]) except Exception,e: return "testparam forgot to assign #<result>" return INTERP_OK

o<testparam> sub (debug, call_level=#<_call_level> myname=#<myname>) ; try commenting out the next line and run again #<result> = [#<myname> * 3] #1 = [#1 * 5] #2 = [#2 * 3] o<testparam> endsub m2

self.params() returns a list of all variable names currently defined. Since myname is local, it goes away after the epilog finishes.

You can recursively call the interpreter from Python code as follows:

self.execute(<NGC code>[,<line number>])Examples:

self.execute("G1 X%f Y%f" % (x,y)) self.execute("O <myprocedure> call", currentline)

You might want to test for the return value being < INTERP_MIN_ERROR. If you are using lots of execute() statements, it is probably easier to trap InterpreterException as shown below.

|

Caution

|

The parameter insertion/retrieval method described in the previous section does not work in this case. It is good enough for just

The recursive call feature is fragile. |

if interpreter.throw_exceptions is nonzero (default 1), and self.execute() returns an error, the exception InterpreterException is raised. InterpreterException has the following attributes:

-

line_number -

where the error occurred

-

line_text -

the NGC statement causing the error

-

error_message -

the interpreter’s error message

Errors can be trapped in the following Pythonic way:

import interpreter interpreter.throw_exceptions = 1 ... try: self.execute("G3456") # raise InterpreterException except InterpreterException,e: msg = "%d: '%s' - %s" % (e.line_number,e.line_text, e.error_message) return msg # replace builtin error message

The canon layer is practically all free functions. Example:

import emccanon def example(self,*args): .... emccanon.STRAIGHT_TRAVERSE(line,x0,y0,z0,0,0,0,0,0,0) emccanon.STRAIGHT_FEED(line,x1,y1,z1,0,0,0,0,0,0) ... return INTERP_OK

The actual canon functions are declared in src/emc/nml_intf/canon.hh and implemented in src/emc/task/emccanon.cc. The implementation of the Python functions can be found in src/emc/rs274ncg/canonmodule.cc.

9.6. Built in modules

The following modules are built in:

-

interpreter -

Exposes internals of the Interp class. See

src/emc/rs274ngc/interpmodule.cc, and thetests/remap/introspectregression test. -

emccanon -

Exposes most calls of

src/emc/task/emccanon.cc.

10. Adding Predefined Named Parameters

The interpreter comes with a set of predefined named parameters for accessing internal state from the NGC language level. These parameters are read-only and global, and hence cannot be assigned to.

Additional parameters may be added by defining a function in the namedparams module. The name of the function defines the name of the new predefined named parameter, which now can be referenced in arbitrary expressions.

To add or redefine a named parameter:

-

Add a

namedparamsmodule so it can be found by the interpreter, -

define new parameters by functions (see below). These functions receive

self(the interpreter instance) as parameter and so can access arbitrary state. Arbitrary Python capabilities can be used to return a value. -

Import that module from the

TOPLEVELscript.

# namedparams.py # trivial example def _pi(self): return 3.1415926535

#<circumference> = [2 * #<radius> * #<_pi>]

Functions in namedparams.py are expected to return a float or int value. If a string is returned, this sets the interpreter error message and aborts execution.

Ònly functions with a leading underscore are added as parameters, since this is the RS274NGC convention for globals.

It is possible to redefine an existing predefined parameter by adding a Python function of the same name to the namedparams module. In this case, a warning is generated during startup.

While the above example isn’t terribly useful, note that pretty much all of the interpreter internal state is accessible from Python, so arbitrary predicates may be defined this way. For a slightly more advanced example, see tests/remap/predefined-named-params.

11. Standard Glue routines

Since many remapping tasks are very similar, I’ve started collecting working prolog and epilog routines in a single Python module. These can currently be found in ncfiles/remap_lib/python-stdglue/stdglue.py and provide the following routines:

11.1. T: prepare_prolog and prepare_epilog

These wrap a NGC procedure for Tx Tool Prepare.

prepare_prologThe following parameters are made visible to the NGC procedure:

-

#<tool>- the parameter of theTword -

#<pocket>- the corresponding pocket

If tool number zero is requested (meaning Tool unload), the corresponding pocket is passed as -1.

It is an error if:

-

No tool number is given as T parameter,

-

the tool cannot be found in the tool table.

Note that unless you set the [EMCIO] RANDOM_TOOLCHANGER=1 parameter, tool and pocket number are identical, and the pocket number from the tool table is ignored. This is currently a restriction.

prepare_epilog-

The NGC procedure is expected to return a positive value, otherwise an error message containing the return value is given and the interpreter aborts.

-

In case the NGC procedure executed the T command (which then refers to the built in T behavior), no further action is taken. This can be used for instance to minimally adjust the built in behavior be preceding or following it with some other statements.

-

Otherwise, the

#<tool>and#<pocket>parameters are extracted from the subroutine’s parameter space. This means that the NGC procedure could change these values, and the epilog takes the changed values in account. -

Then, the Canon command

SELECT_TOOL(#<tool>)is executed.

11.2. M6: change_prolog and change_epilog

These wrap a NGC procedure for M6 Tool Change.

change_prolog-

If there was no preceding T command which caused a pocket to be selected, the prolog aborts with an error message.

-

If cutter radius compensation is on, the prolog aborts with an error message.

Then, the following parameters are exported to the NGC procedure:

-

#<tool_in_spindle>: the tool number of the currently loaded tool -

#<selected_tool>: the tool number selected -

#<selected_pocket>: the selected tool’s tooldata index

-

The NGC procedure is expected to return a positive value, otherwise an error message containing the return value is given and the interpreter aborts.

-

In case the NGC procedure executed the M6 command (which then refers to the built in M6 behavior), no further action is taken. This can be used for instance to minimally adjust the built in behavior be preceding or following it with some other statements.

-

Otherwise, the

#<selected_pocket>parameter is extracted from the subroutine’s parameter space, and used to set the interpreter’scurrent_pocketvariable. Again, the procedure could change this value, and the epilog takes the changed value in account. -

Then, the Canon command

CHANGE_TOOL(#<selected_pocket>)is executed. -

The new tool parameters (offsets, diameter etc) are set.

11.3. G-code Cycles: cycle_prolog and cycle_epilog

These wrap a NGC procedure so it can act as a cycle, meaning the motion code is retained after finishing execution. If the next line just contains parameter words (e.g. new X,Y values), the code is executed again with the new parameter words merged into the set of the parameters given in the first invocation.

These routines are designed to work in conjunction with an argspec=<words> parameter. While this is easy to use, in a realistic scenario you would avoid argspec and do a more thorough investigation of the block manually in order to give better error messages.

The suggested argspec is as follows:

REMAP=G<somecode> argspec=xyzabcuvwqplr prolog=cycle_prolog ngc=<ngc procedure> epilog=cycle_epilog modalgroup=1

This will permit cycle_prolog to determine the compatibility of any axis words give in the block, see below.

cycle_prolog-

Determine whether the words passed in from the current block fulfill the conditions outlined under Canned Cycle Errors.

-

Export the axis words as

<x>,#<y>etc; fail if axis words from different groups (XYZ) (UVW) are used together, or any of (ABC) is given. -

Export L- as

#<l>; default to 1 if not given. -

Export P- as

#<p>; fail if p less than 0. -

Export R- as

#<r>; fail if r not given, or less equal 0 if given. -

Fail if feed rate is zero, or inverse time feed or cutter compensation is on.

-

-

Determine whether this is the first invocation of a cycle G-code, if so:

-

Add the words passed in (as per argspec) into a set of sticky parameters, which is retained across several invocations.

-

-

If not (a continuation line with new parameters) then

-

merge the words passed in into the existing set of sticky parameters.

-

-

Export the set of sticky parameters to the NGC procedure.

cycle_epilog-

Determine if the current code was in fact a cycle, if so, then

-

retain the current motion mode so a continuation line without a motion code will execute the same motion code.

-

11.4. S (Set Speed) : setspeed_prolog and setspeed_epilog

TBD

11.5. F (Set Feed) : setfeed_prolog and setfeed_epilog

TBD

11.6. M61 Set tool number : settool_prolog and settool_epilog

TBD

12. Remapped code execution

12.1. NGC procedure call environment during remaps

Normally, an O-word procedure is called with positional parameters. This scheme is very limiting in particular in the presence of optional parameters. Therefore, the calling convention has been extended to use something remotely similar to the Python keyword arguments model.

See LINKTO G-code/main Subroutines: sub, endsub, return, call.

12.2. Nested remapped codes

Remapped codes may be nested just like procedure calls - that is, a remapped code whose NGC procedure refers to some other remapped code will execute properly.

The maximum nesting level remaps is currently 10.

12.3. Sequence number during remaps

Sequence numbers are propagated and restored like with O-word calls. See tests/remap/nested-remaps/word for the regression test, which shows sequence number tracking during nested remaps three levels deep.

12.4. Debugging flags

The following flags are relevant for remapping and Python - related execution:

|

|

traces execution of O-word subroutines |

|

|

traces execution of remap-related code |

|

|

calls to the Python plug in |

|

|

trace named parameter access |

|

|

user-defined - not interpreted by LinuxCNC |

|

|

user-defined - not interpreted by LinuxCNC |

or these flags into the [EMC]DEBUG variable as needed. For a current list of debug flags see src/emc/nml_intf/debugflags.h.

12.5. Debugging Embedded Python code

Debugging of embedded Python code is harder than debugging normal Python scripts, and only a limited supply of debuggers exists. A working open-source based solution is to use the Eclipse IDE, and the PydDev Eclipse plug in and its remote debugging feature.

To use this approach:

-

Install Eclipse via the the Ubuntu Software Center (choose first selection).

-

Install the PyDev plug in from the Pydev Update Site.

-

Setup the LinuxCNC source tree as an Eclipse project.

-

Start the Pydev Debug Server in Eclipse.

-

Make sure the embedded Python code can find the

pydevd.pymodule which comes with that plug in - it is buried somewhere deep under the Eclipse install directory. Set the thepydevdvariable inutil.pyto reflect this directory location. -

Add

import pydevdto your Python module - see exampleutil.pyandremap.py. -

Call

pydevd.settrace()in your module at some point to connect to the Eclipse Python debug server - here you can set breakpoints in your code, inspect variables, step etc. as usual.

|

Caution

|

pydevd.settrace() will block execution if Eclipse and the Pydev debug server have not been started. |

To cover the last two steps: the o<pydevd> procedure helps to get into the debugger from MDI mode. See also the call_pydevd function in util.py and its usage in remap.involute to set a breakpoint.

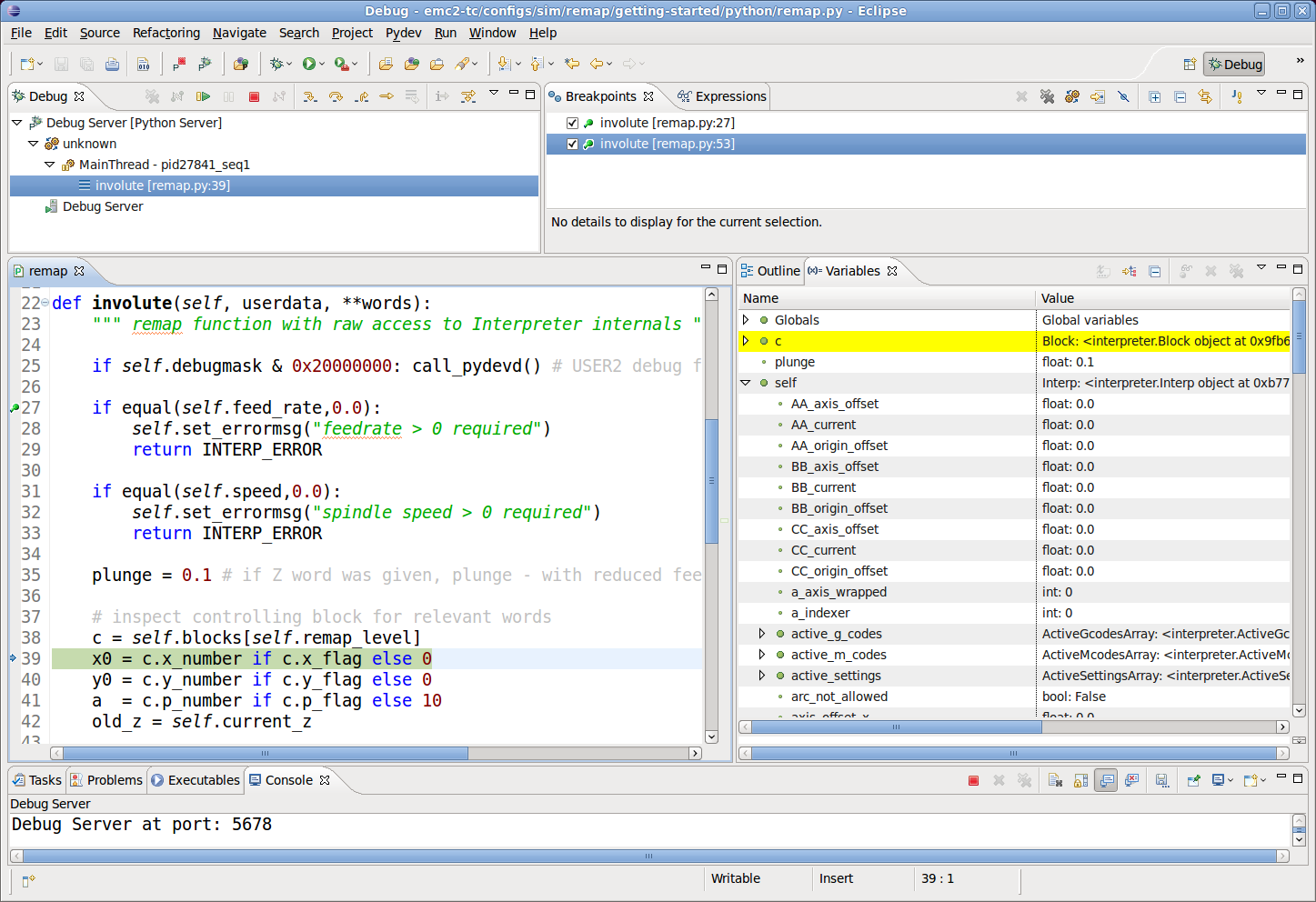

Here’s a screen-shot of Eclipse/PyDevd debugging the involute procedure from above:

See the Python code in configs/sim/axis/remap/getting-started/python for details.

13. Axis Preview and Remapped code execution

For complete preview of a remapped code’s tool path some precautions need to be taken. To understand what is going on, let’s review the preview and execution process (this covers the AXIS case, but others are similar):

First, note that there are two independent interpreter instances involved:

-

One instance in the milltask program, which executes a program when you hit the Start button, and actually makes the machine move.

-

A second instance in the user interface whose primary purpose is to generate the tool path preview. This one executes a program once it is loaded, but it doesn’t actually cause machine movements.

Now assume that your remap procedure contains a G38 probe operation, for example as part of a tool change with automatic tool length touch off. If the probe fails, that would clearly be an error, so you’d display a message and abort the program.

Now, what about preview of this procedure? At preview time, of course it is not known whether the probe succeeds or fails - but you would likely want to see what the maximum depth of the probe is, and assume it succeeds and continues execution to preview further movements. Also, there is no point in displaying a probe failed message and aborting during preview.

The way to address this issue is to test in your procedure whether it executes in preview or execution mode. This can be checked for by testing the #<_task> predefined named parameter - it will be 1 during actual execution and 0 during preview. See configs/sim/axis/remap/manual-toolchange-with-tool-length-switch/nc_subroutines/manual_change.ngc for a complete usage example.

Within Embedded Python, the task instance can be checked for by testing self.task - this will be 1 in the milltask instance, and 0 in the preview instance(s).

14. Remappable Codes

14.1. Existing codes which can be remapped

The current set of existing codes open to redefinition is:

-

Tx (Prepare)

-

M6 (Change tool)

-

M61 (Set tool number)

-

M0 (pause a running program temporarily)

-

M1 (pause a running program temporarily if the optional stop switch is on)

-

M7 (активировать туман охлаждающей жидкости)

-

M8 (activate coolant flood)

-

M9 (deactivate coolant mist and flood)

-

M60 (exchange pallet shuttles and then pause a running program temporarily)

-

M62 .. M65 (управление цифровым выводом)

-

M66 (wait on input)

-

M67, M68 (analog output control)

-

S (set spindle speed)

-

F (set feed)

14.2. Currently unallocated G-codes:

Currently unallocated G-codes (for remapping) must be selected from the blank areas of the following tables. All the listed G-codes are already defined in the current implementation of LinuxCNC and may not be used to remap new G-codes. (Developers who add new G-codes to LinuxCNC are encouraged to also add their new G-codes to these tables.)

| # | Gxx | Gxx.1 | Gxx.2 | Gxx.3 | Gxx.4 | Gxx.5 | Gxx.6 | Gxx.7 | Gxx.8 | Gxx.9 |

|---|---|---|---|---|---|---|---|---|---|---|

00 |

|

|||||||||

01 |

|

|||||||||

02 |

|

|||||||||

03 |

|

|||||||||

04 |

|

|||||||||

05 |

|

|

|

|

||||||

06 |

||||||||||

07 |

|

|||||||||

08 |

|

|||||||||

09 |

| # | Gxx | Gxx.1 | Gxx.2 | Gxx.3 | Gxx.4 | Gxx.5 | Gxx.6 | Gxx.7 | Gxx.8 | Gxx.9 |

|---|---|---|---|---|---|---|---|---|---|---|

10 |

|

|||||||||

11 |

||||||||||

12 |

||||||||||

13 |

||||||||||

14 |

||||||||||

15 |

||||||||||

16 |

||||||||||

17 |

|

|

||||||||

18 |

|

|

||||||||

19 |

|

|

| # | Gxx | Gxx.1 | Gxx.2 | Gxx.3 | Gxx.4 | Gxx.5 | Gxx.6 | Gxx.7 | Gxx.8 | Gxx.9 |

|---|---|---|---|---|---|---|---|---|---|---|

20 |

|

|||||||||

21 |

|

|||||||||

22 |

||||||||||

23 |

||||||||||

24 |

||||||||||

25 |

||||||||||

26 |

||||||||||

27 |

||||||||||

28 |

|

|

||||||||

29 |

| # | Gxx | Gxx.1 | Gxx.2 | Gxx.3 | Gxx.4 | Gxx.5 | Gxx.6 | Gxx.7 | Gxx.8 | Gxx.9 |

|---|---|---|---|---|---|---|---|---|---|---|

30 |

|

|

||||||||

31 |

||||||||||

32 |

||||||||||

33 |

|

|

||||||||

34 |

||||||||||

35 |

||||||||||

36 |

||||||||||

37 |

||||||||||

38 |

||||||||||

39 |

| # | Gxx | Gxx.1 | Gxx.2 | Gxx.3 | Gxx.4 | Gxx.5 | Gxx.6 | Gxx.7 | Gxx.8 | Gxx.9 |

|---|---|---|---|---|---|---|---|---|---|---|

40 |

|

|||||||||

41 |

|

|

||||||||

42 |

|

|

||||||||

43 |

|

|

||||||||

44 |

||||||||||

45 |

||||||||||

46 |

||||||||||

47 |

||||||||||

48 |

||||||||||

49 |

|

| # | Gxx | Gxx.1 | Gxx.2 | Gxx.3 | Gxx.4 | Gxx.5 | Gxx.6 | Gxx.7 | Gxx.8 | Gxx.9 |

|---|---|---|---|---|---|---|---|---|---|---|

50 |

||||||||||

51 |

||||||||||

52 |

||||||||||

53 |

|

|||||||||

54 |

|

|||||||||

55 |

|

|||||||||

56 |

|

|||||||||

57 |

|

|||||||||

58 |

|

|||||||||

59 |

|

|

|

|

| # | Gxx | Gxx.1 | Gxx.2 | Gxx.3 | Gxx.4 | Gxx.5 | Gxx.6 | Gxx.7 | Gxx.8 | Gxx.9 |

|---|---|---|---|---|---|---|---|---|---|---|

60 |

|

|||||||||

61 |

|

|

||||||||

62 |

||||||||||

63 |

||||||||||

64 |

|

|||||||||

65 |

||||||||||

66 |

||||||||||

67 |

||||||||||

68 |

||||||||||

69 |

| # | Gxx | Gxx.1 | Gxx.2 | Gxx.3 | Gxx.4 | Gxx.5 | Gxx.6 | Gxx.7 | Gxx.8 | Gxx.9 |

|---|---|---|---|---|---|---|---|---|---|---|

70 |

|

|||||||||

71 |

|

|

|

|||||||

72 |

|

|

|

|||||||

73 |

||||||||||

74 |

||||||||||

75 |

||||||||||

76 |

|

|||||||||

77 |

||||||||||

78 |

||||||||||

79 |

| # | Gxx | Gxx.1 | Gxx.2 | Gxx.3 | Gxx.4 | Gxx.5 | Gxx.6 | Gxx.7 | Gxx.8 | Gxx.9 |

|---|---|---|---|---|---|---|---|---|---|---|

80 |

|

|||||||||

81 |

|

|||||||||

82 |

|

|||||||||

83 |

|

|||||||||

84 |

|

|||||||||

85 |

|

|||||||||

86 |

|

|||||||||

87 |

|

|||||||||

88 |

|

|||||||||

89 |

|

| # | Gxx | Gxx.1 | Gxx.2 | Gxx.3 | Gxx.4 | Gxx.5 | Gxx.6 | Gxx.7 | Gxx.8 | Gxx.9 |

|---|---|---|---|---|---|---|---|---|---|---|

90 |

|

|

||||||||

91 |

|

|

||||||||

92 |

|

|

|

|

||||||

93 |

|

|||||||||

94 |

|

|||||||||

95 |

|