1. License

PlasmaC and all of its related software are released under GPLv2.

2. Introduction

PlasmaC is a plasma cutting configuration that is loaded on top of LinuxCNC v2.8 or later. It includes a HAL component plus GUI configurations for both Axis and Gmoccapy. There is also an option to have the Axis GUI display in portrait mode, see Axis <machine_name>.ini file.

The desired LinuxCNC GUI (Axis or Gmoccapy) with PlasmaC component loaded should be chosen prior to starting the LinuxCNC installation process as switching between Axis and Gmoccapy requires a fresh configuration to be created.

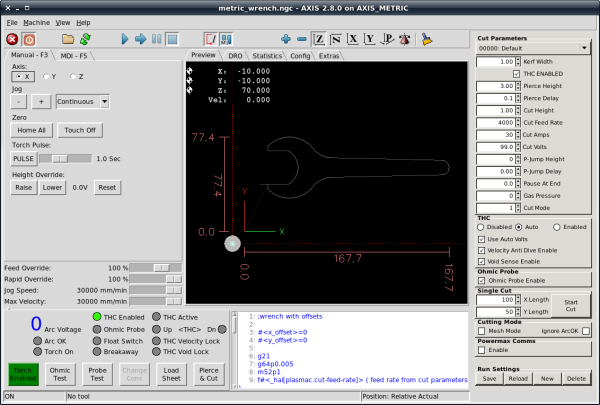

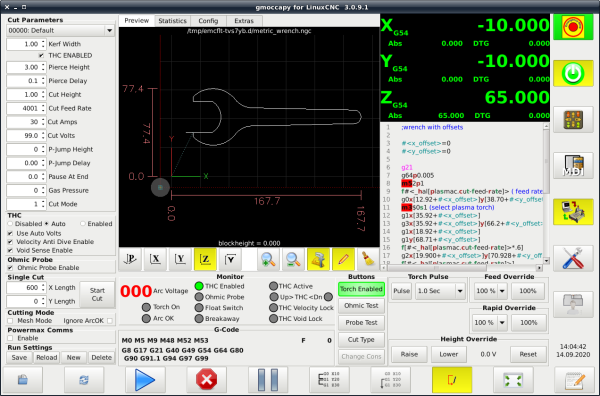

Screenshot examples of PlasmaC loaded on top of both the Axis and Gmoccapy GUIs are below:

AXIS:

GMOCCAPY:

The PlasmaC component should run on any hardware that is supported by LinuxCNC provided there are enough hardware I/O pins to fulfill the requirements of a plasma configuration.

If the user is new to CNC plasma cutting, it is recommended that they read the Plasma CNC Primer document which is a generic introduction to CNC plasma cutting.

|

Note

|

Except where noted, this guide assumes the user is using the latest version of PlasmaC. PlasmaC update notices are posted at: https://forum.linuxcnc.org/plasmac/37233-plasmac-updates Refer to PlasmaC Version to see the current PlasmaC version in the Config Panel. If the Version Number is not present, the user’s version of PlasmaC is before v0.121. See Update PlasmaC for information on updating PlasmaC. |

3. Installing LinuxCNC

The preferred method for installing LinuxCNC (which contains PlasmaC by default) is via an ISO image as described below.

|

Note

|

It is possible to install and run LinuxCNC on a variety of Linux distributions however that is beyond the scope of this User Guide. If the user wishes to install a Linux distribution other than those recommended, they will first need to install the preferred Linux distribution and then install LinuxCNC v2.8 or later along with any required dependencies. |

3.1. If The User Does Not Have Linux Installed

Installation instructions are available at: http://linuxcnc.org/docs/devel/html/getting-started/getting-linuxcnc.html

Following these instructions will yield a machine with the current stable branch (v2.8) of LinuxCNC.

3.2. If The User Has Linux with LinuxCNC v2.7

Upgrading instruction are available at: http://linuxcnc.org/docs/devel/html/getting-started/updating-linuxcnc.html

Following these instructions will yield a machine with the current stable branch (v2.8) of LinuxCNC.

3.3. Creating A Working Base Machine Configuration

|

Note

|

"Base machine configuration" means a complete working system without any of the plasma connections shown in the I/O Requirements section. All axes should be working and tuned for best performance and all home and limit switches for X, Y, and Z axes (if installed) should be operating correctly. |

|

Important

|

DO NOT ADD ANY OF THE PLASMA CONNECTIONS SHOWN IN THE I/O REQUIREMENTS SECTION AT THIS TIME, THESE I/O’S WILL BE ADDED LATER DURING THE PlasmaC CONFIGURATION USING THE CONFIGURATOR. |

Some recommended settings:

-

Z MINIMUM_LIMIT should be just below top of the slats with allowances for float_switch_travel and over travel tolerance. For example, if the user’s float switch takes 4mm (0.157") to activate then set the Z minimum to 5mm (0.197") plus an allowance for overrun (as calculated using the equation below) below the lowest slat.

-

Z MAXIMUM_LIMIT should be the highest the user wants the Z axis to travel (it must not be lower than Z HOME_OFFSET).

-

Z HOME should be set to be approximately 5mm (0.196") below the maximum limit.

-

Floating Head - it is recommended that a floating head be used and that it has enough movement to allow for overrun during probing. Overrun can be calculated using the following formula:

o = 0.5 × a × (v ÷ a)^2where: o = overrun, a = acceleration in units/sec2 and v = velocity in units/sec.

Metric example: given a Z axis MAX_ACCELERATION of 600mm/s2 and MAX_VELOCITY of 60mm/s, the overrun would be 3mm.

Imperial example: given a Z axis MAX_ACCELERATION of 24in/s2 and MAX_VELOCITY of 2.4in/s, the overrun would be 0.12in.

On machines that will utilize an ohmic probe as the primary method of probing, it is highly recommended to install a switch on the floating head as a backup means of stopping Z motion in the event of ohmic probe failure due to dirty surfaces.

The user may opt to create a base machine manually or one of the existing configuration helpers may be used:

|

Note

|

It is highly recommended to keep the base machine config simple until it has been fully tested and tuned. If using Stepconf or Pncconf then deselect the VCP Panel, spindle, manual tool change, and classic ladder options. Any of the aforementioned options can be added manually at a later time should the need arise. |

|

Important

|

DO NOT ADD ANY OF THE PLASMA SPECIFIC I/O REQUIREMENTS TO THE PNCCONF OR STEPCONF WIZARDS. |

If using a Mesa Electronics board, use the pncconf wizard (enter the following command into a terminal window):

pncconfIf using a parallel port, use the stepconf wizard (enter the following command into a terminal window):

stepconfIf using a Pico Systems board:

This LinuxCNC forum thread may be helpful.

If the user already has a dual motor gantry configuration that requires the configuration to be hand edited:

This LinuxCNC forum thread may be helpful.

|

Important

|

BEFORE PROCEEDING, THE USER SHOULD BE ABLE TO HOME THE MACHINE, ZERO EACH AXIS, JOG ALL AXES TO SOFT LIMITS WITHOUT CRASHING, AND RUN TEST G-CODE PROGRAMS WITHOUT ANY ERRORS. |

ONLY WHEN this criteria is met should the user proceed with configuring PlasmaC "on top" of a working machine by running the configurator.

|

Caution

|

DO NOT CONTINUE UNTIL THE BASE MACHINE IS CONFIGURED AND WORKING. |

4. Plasma Specific I/O Considerations

Prior to starting a plasma configuration, it is important that the user has a firm understanding of the operating modes available, as well as the I/O’s that are required for successful plasma operation.

4.1. Modes

PlasmaC requires the selection of one of following three operating modes:

Mode |

Description |

0 |

Uses an external arc voltage input to calculate both Arc Voltage (for Torch Height Control) and Arc OK. |

1 |

Uses an external arc voltage input to calculate Arc Voltage (for Torch Height Control). |

2 |

Uses an external Arc OK input for Arc OK. |

|

Important

|

If the plasma power source has an Arc OK (Transfer) output then it is recommended to use that for Arc OK rather than the soft (calculated) Arc OK provided by mode 0. |

4.2. Available I/Os

|

Note

|

This section only touches on the hardware I/O’s required for the PlasmaC component. Base machine requirements such as limit switches, home switches, etc. are in addition to these and should already be configured and working prior to the user running the configurator. |

Name |

Modes |

Description |

Arc Voltage |

0, 1 |

Analog input; optional. |

Arc OK |

1, 2 |

Digital input; optional. |

Float Switch |

0, 1, 2 |

Digital input; optional, see info below table: |

Ohmic Probe |

0, 1, 2 |

Digital input; optional, see info below table: |

Ohmic Probe Enable |

0, 1, 2 |

Digital output; optional, see info below table: |

Breakaway Switch |

0, 1, 2 |

Digital input; optional, see info below table: |

Torch On |

0, 1, 2 |

Digital output; required. |

Move Up |

2 |

Digital input; optional. |

Move Down |

2 |

Digital input; optional. |

Scribe Arming |

0, 1, 2 |

Digital output; optional. |

Scribe On |

0, 1, 2 |

Digital output; optional. |

Only one of either Float Switch or Ohmic Probe is required. If both are used then Float Switch will be a fallback if Ohmic Probe is not sensed.

If Ohmic Probe is used then Ohmic Probe Enable is required to be checked on the PlasmaC GUI.

Breakaway Switch is not mandatory because Float Switch is treated the same as a breakaway when not probing. If they are two separate switches, and there are not enough inputs on the breakout board, they could be combined and connected as a Float Switch.

|

Note

|

The minimum I/O requirement for a PlasmaC configuration to function are: Arc Voltage input OR Arc OK input, Float Switch input, and Torch On output. To reiterate, in this case PlasmaC will treat the float switch as a breakaway switch when it is not probing. |

|

Important

|

THE ABOVE PINS WILL BE ENTERED LATER DURING THE PLASMAC CONFIGURATOR PROCESS. MAKE NOTE OF THE CORRESPONDING INPUTS AND OUTPUTS ON THE BREAKOUT BOARD DURING WIRING. THESE PINS SHOULD NOT BE USED TO CREATE THE BASE MACHINE .HAL FILE. |

5. Installing PlasmaC To A Base Machine Via The Configurator

By this point, the user NEEDS to have a fully tested and working base machine configuration without any connections to the plasma specific I/Os before proceeding. It is much more difficult to edit a base machine configuration after adding PlasmaC as pncconf and stepconf can no longer be used to help edit the configuration.

|

Caution

|

DO NOT PROCEED UNTIL THE BASE MACHINE IS COMPLETE. |

|

Note

|

If the user is using a Mesa Electronics THCAD card for arc voltage measurement, see Mesa THCAD before proceeding. |

Installing a PlasmaC configuration to a base machine is done from the Configurator.

Enter the following command into a terminal window:

python /usr/share/doc/linuxcnc/examples/sample-configs/by_machine/plasmac/configurator.py5.1. Configure

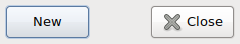

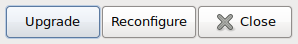

The selection window is now visible:

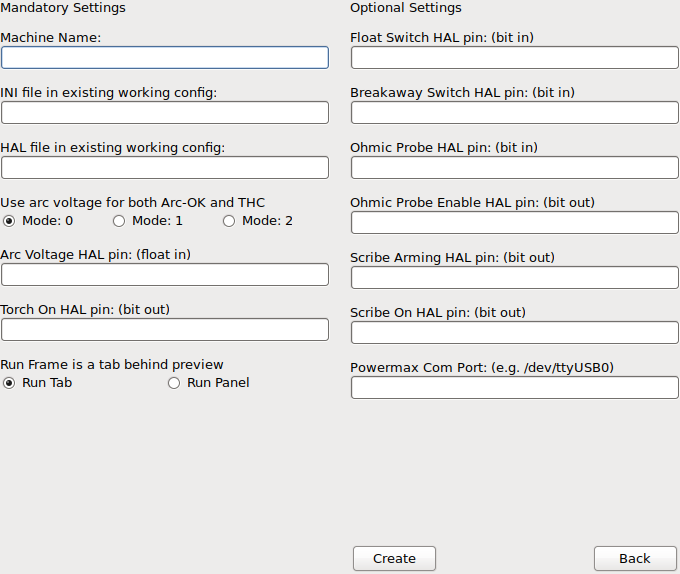

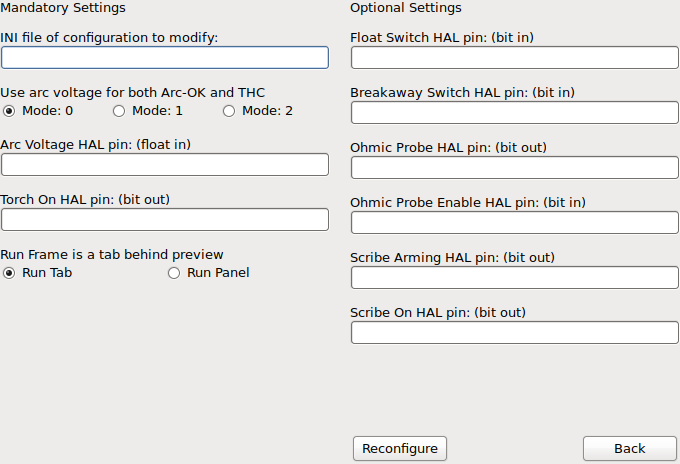

Select New from the selection window, this will show an info dialog, select Continue and the New Configuration window will display.

|

Note

|

There will be different fields visible depending on the mode selected. |

HAL connection examples in the following table show examples for both a parallel port config and a Mesa 7i96 config. Change the pin names as required to suit the breakout board configuration.

Field |

Description |

Examples |

Machine Name |

The new name for the machine. This will create a ~/linuxcnc/<machine_name> directory and a <machine_name>.ini file. |

plasma_table.ini. |

INI File |

This is the .ini file that was created as a result of making a working and tested base machine configuration. |

base.ini |

HAL File |

This is the .hal file that was created as a result of making a working and tested base machine configuration. |

base.hal |

Mode |

Select the required mode based on the following criteria: |

1 |

Arc Voltage |

Required for Modes 0 and 1 only. |

Parallel Port Example: encoder.0.velocity |

Torch On |

Required for All modes. |

Parallel Port Example: parport.0.pin-16-out |

Arc OK |

Required for Modes 1 and 2 only. |

Parallel Port Example: parport.0.pin-10-in-not |

Ohmic Probe |

Required if using an ohmic probe. |

Parallel Port Example: parport.0.pin-11-in |

Ohmic Probe Enable |

Required if using an ohmic probe. |

Parallel Port Example: parport.1.pin-01-out |

Float Switch |

Required if using a float switch. |

Parallel Port Example: parport.0.pin-12-in |

Breakaway Switch |

Required if using a breakaway switch. |

Parallel Port Example: parport.0.pin-13-in |

Move Up |

Required for Mode 2 only. |

Parallel Port Example: parport.1.pin-10-in |

Move Down |

Required for Mode 2 only. |

Parallel Port Example: parport.1.pin-11-in |

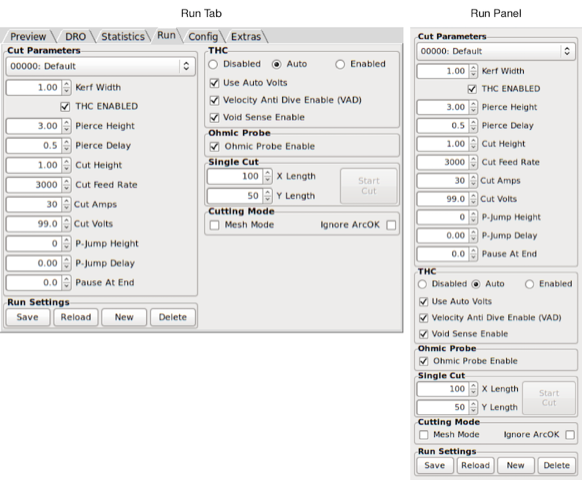

Run Panel |

Run Tab - Selecting this option places the PlasmaC run frame in a tab behind the preview tab. |

Run Tab |

Scribe Arming |

Required if using a scribe. |

Parallel Port Example: parport.1.pin-16-out |

Scribe On |

Required if using a scribe. |

Parallel Port Example: parport.1.pin-16-out |

PowerMax Comms |

Required if using PowerMax serial communications. |

/dev/ttyUSB0 |

|

Note

|

If unsure of the HAL pin’s full name, the user may start LinuxCNC for the base machine and run HalShow for a full listing of all HAL pins. |

Fill in the required entries to suit the machine wiring/breakout board configuration, click Create and a working PlasmaC configuration will be created in the following directory: ~/linuxcnc/configs/<machine_name>

The newly created PlasmaC configuration can be run by entering the following command into a terminal window (change "<machine_name>" to the machine name entered into the PlasmaC configurator):

linuxcnc ~/linuxcnc/configs/<machine_name>/<machine_name>.iniAfter creating a new configuration some initial setup is required before using the PlasmaC component.

5.2. Initial Setup

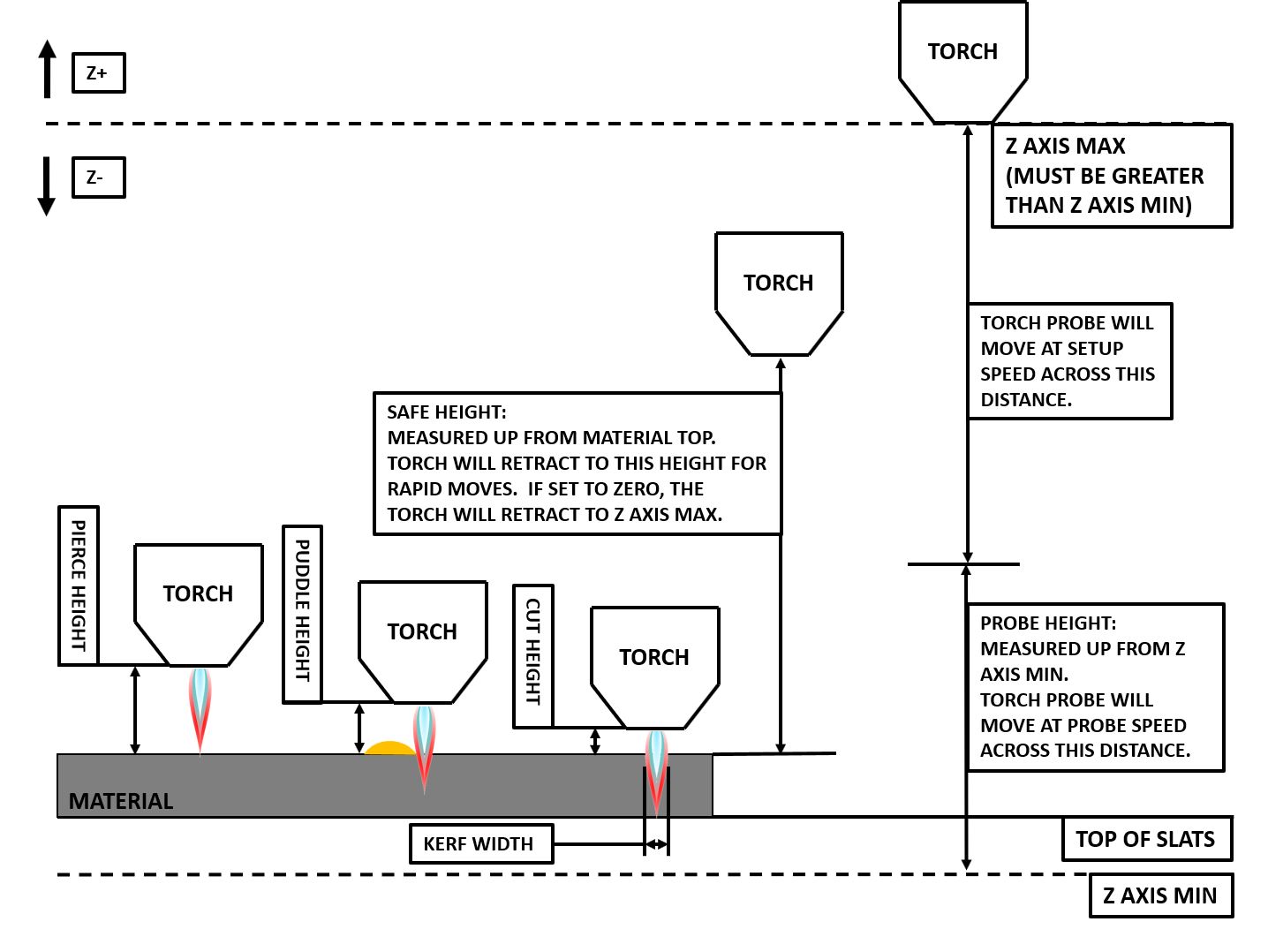

The following heights diagram will help the user visualize the different heights involved in plasma cutting and how they are measured:

After running the command at the end of section 5.1, LinuxCNC should be running with the PlasmaC panels visible.

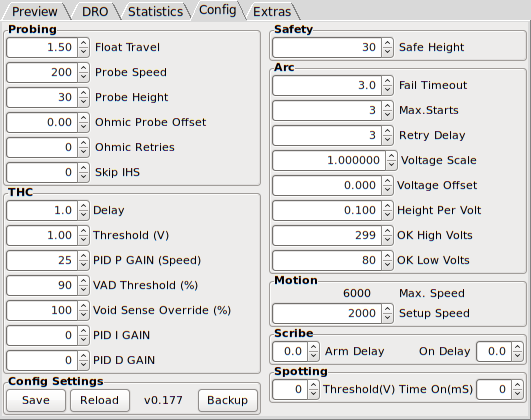

Click on the Config tab to open the Config Panel and ensure every one of these settings is tailored to the machine.

To set the Z axis DRO relative to the Z axis MINIMUM_LIMIT, the user should perform the following steps. It is important to understand that in PlasmaC, touching off the Z axis DRO has no effect on the Z axis position while running a G-Code program. These steps simply allow the user to more easily set the probe height as after performing the steps, the displayed Z axis DRO value will be relative to Z axis MINIMUM_LIMIT.

-

The user should be familiar with the recommended Z Axis Settings

-

Home the Z axis.

-

Ensure there is nothing below the torch then jog the Z axis down until it stops at the Z axis MINIMUM_LIMIT then click Touch Off with the Z axis selected to set the Z axis at zero offset.

-

Home the Z axis again.

If the machine is equipped with a float switch then the user will need to set the offset in the Config Panel. This will be done by running a "Probe Test" cycle.

-

Check that the Probe Speed and the Probe Height in the Config Panel are correct. PlasmaC can probe at the full Z axis velocity so long as the machine has enough movement in the float switch to absorb any overrun. If the machine is suitable, the user could set the Probe Height to a value near the Z axis minimum and do all probing at full speed.

-

If the machine is not already homed and in the home position, Home the machine.

-

Place some material on the slats under the torch.

-

Press the Probe Test button.

-

The Z axis will probe down, find the material then move up to the specified Pierce Height as set by the currently selected material. The torch will wait in this position for the time set in the <machine_name>.ini file. The default probe test hold time is 30 seconds, this value may be edited in the <machine_name>.ini file. After this the torch will return to the starting height.

-

Measure the distance between the material and the tip of the torch while the torch is waiting at Pierce Height.

-

If the measurement is greater than the Pierce Height of the currently selected material, then reduce the "Float Travel" on the Config Panel by the difference between the measured value and the specified value. If the measurement is less than Pierce Height of the currently selected material, then increase the "Float Travel" on the Config Panel by the difference between the specified value and the measured value.

-

After the adjustments to the "Float Travel" have been made, repeat the process from #4 above until the measured distance between the material and the torch tip matches the Pierce Height of the currently selected material.

|

Note

|

If the amount of time between the torch contacting the material and when the torch moves up and comes to rest at the Pierce Height seems excessive, see the probing section for a possible solution. |

|

Important

|

IF USING A Mesa Electronics THCAD THEN UP UNTIL NOW THE Voltage Scale VALUE WAS OBTAINED MATHEMATICALLY. IF THE USER INTENDS TO USE CUT VOLTAGES FROM A MANUFACTURE’S CUT CHART THEN IT WOULD BE ADVISABLE TO DO MEASUREMENTS OF ACTUAL VOLTAGES AND FINE TUNE THE Voltage Scale AND Voltage Offset. |

|

Caution

|

PLASMA CUTTING VOLTAGES CAN BE LETHAL, IF THE USER IS NOT EXPERIENCED IN DOING THESE MEASUREMENTS GET SOME QUALIFIED HELP. |

5.3. Reconfigure An Existing PlasmaC Configuration

The Configurator may also be used to reconfigure an existing PlasmaC configuration to change settings instead of modifying files manually.

The Configurator is only able to modify:

-

The HAL pins connecting PlasmaC to the machine.

-

The mode used by PlasmaC.

-

The position of the Run Panel in the GUI.

Reconfiguring a PlasmaC configuration is done from the Configurator which is located in the configuration directory.

It is recommended that a backup copy of the existing PlasmaC configuration is made before proceeding.

To start the configurator enter the following command into a terminal window:

python linuxcnc/<the_users_configuration_directory>/configurator.pyThe selection window is now visible:

Select Reconfigure from the selection window, this shows an info dialog, select Continue and the Reconfigure window will display:

Select the <machine_name>.ini file of the PlasmaC configuration to reconfigure.

If the user changes modes, the entry boxes will change depending on the currently selected mode.

When all entries are correct, click Reconfigure and the user’s PlasmaC configuration will be reconfigured.

Entry descriptions can be found here

|

Note

|

Machine Name and <machine_name>.hal File can not be modified. |

6. Other PlasmaC Setup Considerations

6.1. Lowpass Filter

The PlasmaC component has an built in lowpass filter that if used is applied to the plasmac.arc-voltage-in input pin to filter any noise that could cause erroneous voltage readings. The lowpass filter should only be used after using Halscope to determine the required frequency and whether the amplitude of the noise is large enough to cause any issues. For most plasma machines lowpass is not required and should not be used unless it is required.

The HAL pin assigned to this filter is plasmac.lowpass-frequency and is set to 0 (disabled) by default. To apply a lowpass filter to the arc-voltage, the user would edit the following entry in the <machine_name>_connections.hal file in the machine’s configuration directory to add the appropriate cutoff frequency as measured in Hertz (Hz).

For example:

setp plasmac.lowpass-frequency 100The above example would give a cutoff frequency of 100Hz.

6.2. Contact Debounce

Contact bounce from mechanical relays, switches, or external interference may cause some inconsistent behavior of the following switches:

-

Float Switch

-

Ohmic Probe

-

Breakaway Switch

-

Arc OK (for modes 1 & 2)

Due to the fact that the software is capable of sampling rates faster than the contact bounce period, it is possible that the software may see contact bounce as several changes in input states occurring in a very small time period, and incorrectly interpreting a very quick on-off of the input. One method of mitigating contact bounce is to "debounce" the input. To summarize debounce, as soon as the software sees an input with a debounce delay change states, it waits for a prescribed delay period before checking the state of the input again. After the debounce period the software will regard state changes as normal behavior of the input and react accordingly.

Debounce periods can be changed by editing the appropriate debounce value in the <machine_name>_connections.hal file in the <machine_name> config folder.

Each increment of delay adds one servo thread cycle to the debounce time. For example: given a servo thread period of 1000000 (measured in nano seconds), a debounce delay of 5 would equate to 5000000ns, or 5ms.

For the Float and Ohmic switches this equates to a 0.001mm (0.00004") increase in the probed height result.

It is recommended to keep the debounce values as low as possible while still achieving consistent results. Using Halscope to plot the inputs is a good way to establish the correct value.

There are two versions of contact debouncing available in PlasmaC. The method used is determined by when the configuration was first created. There is no automatic update method available to convert from the original debounce setup to the alternate debounce setup as it is difficult to apply the necessary changes without understanding any manual edits that may have been made to the machine’s configuration files and potentially "breaking" a working configuration. If the user wishes to change from the original setup to the new setup, they must do so manually.

6.2.1. Debounce (For PlasmaC installations using v0.173 and later)

For PlasmaC installations using v0.173 (released 11 Sep 2020) and later, debounce is achieved by using the HAL dbounce component which is a later alternative to the original debounce component. This new version allows for the loading and naming of individual debounce instances and is compatible with Twopass HAL file processing.

All four signals above have an individual debounce component so the debounce periods can be catered individually to each input. Any changes made to these values in the <machine_name>_connections.hal file will not be overwritten by later updates of PlasmaC.

The default delay for all four inputs is five servo thread periods. In most cases this value will work quite well. If any of the inputs do not use mechanical switches, it may be possible to either reduce or remove the delay for those inputs.

If debounce is required for other equipment like home or limit switches etc then more dbounce components may added in any of the HAL files without any regard to the signals listed here.

6.2.2. Debounce (For PlasmaC installations using v0.172 and earlier)

For PlasmaC installations using v0.172 (released 10 Sep 2020) and earlier, debounce is achieved by using the HAL debounce component. If the user installed PlasmaC using a version before v0.173 (released 11 Sep 2020), and they wish to use the new debounce method, they will need to follow the directions in the Changing Debounce Type section.

In a standard configuration created before this date, only the Float Switch, Ohmic Probe, and Breakaway Switch inputs are debounced and the single delay value applies to all three switches simultaneously. These inputs could separated and controlled individually by using an exclusive debounce group for each signal.

If debounce is required for other equipment like home or limit switches then either more filters could be added to the existing group or another group could be added by editing the existing loadrt debounce line in the <machine_name>_connections.hal file.

Change the default line below:

loadrt debounce cfg=3to:

loadrt debounce cfg=4This would add a new filter named debounce.0.3 that could be used to debounce another switch input signal.

Change the default line below (and add the two additional lines):

loadrt debounce cfg=3to:

loadrt debounce cfg=3,1

setp debounce.1.delay n

addf debounce.1 servo-threadThis would add a new group named debounce.1 with a new filter named debounce.1.0 having a delay of n servo cycles that could be used to debounce another switch input signal. The user will have to change "n" to the appropriate amount of delay for the new input.

6.2.3. Changing Debounce Type

It is possible to manually change from the old debounce setup to the later debounce setup by editing the <machine_name>_connections.hal file. If this is done, the naming convention as used in this example connections.hal file must be followed.

It is also necessary to edit the <machine_name>.ini file to add the following change:

# required for upgrades (DO NOT CHANGE)

LAST_MAJOR_UPGRADE = 0.144to:

# required for upgrades (DO NOT CHANGE)

LAST_MAJOR_UPGRADE = 0.144

DBOUNCE = 1Failure to follow this procedure will lead to errors when loading LinuxCNC.

6.3. Desktop Launcher

If a link to the launch the configuration was not created when creating the config, the user could create a desktop launcher to the config by right clicking on the desktop and selecting Create Launcher or similar. This will bring up a dialog to create a launcher. Give the icon a nice short name, enter anything for the command and click OK.

After the launcher appears on the desktop, right click on it and then edit it with the user’s editor of choice. Edit the file so it looks similar to:

[Desktop Entry]

Comment=

Terminal=false

Name=LinuxCNC

Exec=sh -c "linuxcnc $HOME/linuxcnc/configs/<machine_name>/<machine_name>.ini"

Type=Application

Icon=/usr/share/pixmaps/linuxcncicon.pngIf the user would like a terminal window to open behind the GUI window then change the Terminal line to:

Terminal=trueDisplaying a terminal can be handy for error and information messages.

6.4. PlasmaC Files

After a successful PlasmaC installation, the following files are created in the configuration directory:

Filename |

Function |

<machine_name>.ini |

A configuration file that includes the base system parameters, as well as various settings required by PlasmaC. |

<machine_name>.hal |

A HAL connections file that includes the base system I/O HAL pin connections to LinuxCNC. |

<machine_name>_connections.hal |

A HAL connections that includes I/O HAL pin connections specific to PlasmaC. |

<machine_name>_material.cfg |

This file is used to store the material settings from the Run Panel |

postgui.tcl |

A HAL file that is ran after the GUI has loaded for user customizing. |

tool.tbl |

A tool table used to store offset information for additional tools (scribe, etc.) used by the PlasmaC configuration. |

|

Note

|

<machine_name> is whatever name the user entered into the "Machine Name" field of the configurator NOTE: Custom commands are allowed in <machine_name>_connections.hal and the postgui.hal files as they are not overwritten during updates. |

In addition to the above files, the following links are created to files or directories in the source directory:

Filename |

Function |

test |

A directory containing a test panel for simulation configurations. |

wizards |

A directory containing the files relating to the shape library to support the Conversational feature within PlasmaC. |

configurator.py |

A Python script used to configure a new PlasmaC configuration. It is also used to updates/re-configure an existing PlasmaC configuration. |

materialverter.py |

A Python script used to convert tool libraries from various CAM software and populate the PlasmaC material file. |

pmx_test.py |

A Python script used to provide a panel to find the correct serial port and test communications between PlasmaC and a PowerMax power source. |

versions.html |

A HTML file that will list the complete version and update history of PlasmaC. |

Finally, the following directories are created:

Folder |

Function |

backup |

A directory that contains backups of files that changed during updates to an existing installation and the original .hal and .ini files. |

plasmac |

A directory that contains links to the PlasmaC source files. |

After running a new configuration for the first time the following files will be created in the configuration directory:

Filename |

Function |

<machine_name>_config.cfg |

This file is used to store the configuration settings from the Config Panel |

<machine_name>_run.cfg |

This file is used to store the configuration settings from the Run Panel |

<machine_name>_wizards.cfg |

This file is used to store the configuration settings from the Conversational shape library |

plasmac_stats.var |

This file is used to store the saved cutting statistics |

|

Note

|

The configuration files (<machine_name>.ini and <machine_name>.hal) that are created by PlasmaC are notated to explain the requirements to aid in manual manipulation of these configurations. They may be edited with any text editor. |

|

Note

|

The .cfg files are plain text and may be edited with any text editor. |

6.5. INI File

PlasmaC requires some specific <machine_name>.ini file variables as follows:

6.5.1. Common

[PLASMAC] Section

MODE = 0 (use external arc voltage in for Arc Voltage)

(use external arc voltage in for Arc OK)

= 1 (use external arc voltage in for Arc Voltage)

(use external Arc OK in for Arc OK)

= 2 (Use external Arc OK in for Arc OK)

(use external up/down for THC)

CONFIG_DISABLE = 0 (0=enable or 1=disable the PlasmaC Config Panel)

PAUSED-MOTION-SPEED = n (multiply cut-feed-rate by this value for paused motion speed)

TORCH-PULSE-TIME = n (torch on time when manual pulse requested)

BUTTON_n_NAME = <NAME> (the name of a custom user buttons)

BUTTON_n_CODE = <CODE> (the code run by a custom user button)

BUTTON_n_IMAGE = <IMAGE> (the image displayed by buttons 10~19)[FILTER] Section

PROGRAM_EXTENSION = .ngc (filter gcode files)

ngc = ./plasmac/plasmac_gcode.py

nc = ./plasmac/plasmac_gcode.py

tap = ./plasmac/plasmac_gcode.py[RS274NGC] Section

RS274NGC_STARTUP_CODE = o<metric_startup> call (machine startup G-Code)

SUBROUTINE_PATH = ./:./plasmac:../../nc_files/subroutines (./ must be in this path)

FEATURES = 12 (for reading .ini and HAL variables)

USER_M_PATH = ./:./plasmac (for M190 material change)|

Important

|

SEE PATH TOLERANCE FOR RS274NGC_STARTUP_CODE INFORMATION RELATED TO G64. |

[HAL] Section

TWOPASS = on (needed for multiple .hal files)

HALFILE = <machine_name>.hal (your base machine .hal file)

HALFILE = plasmac.tcl (the standard PlasmaC .hal file )

HALFILE = <machine_name>_connections.hal (PlasmaC connections to the machine)

HALFILE = HALUI = halui (required)The <machine_name>.hal file has num_spindles=[TRAJ]SPINDLES appended to the end of the loadrt motmod line to allow the addition of a scribe, if required.

|

Note

|

The user could place custom HAL commands in the <machine_name>_connections.hal file as this file is not overwritten by PlasmaC updates. |

[TRAJ] Section

SPINDLES = 3[AXIS_X] Section

MAX_VELOCITY = double the value in the corresponding joint

MAX_ACCELERATION = double the value in the corresponding joint

OFFSET_AV_RATIO = 0.5[AXIS_Y] Section

MAX_VELOCITY = double the value in the corresponding joint

MAX_ACCELERATION = double the value in the corresponding joint

OFFSET_AV_RATIO = 0.5[AXIS_Z] Section

MIN_LIMIT = the top of your slats or just below

MAX_VELOCITY = double the value in the corresponding joint

MAX_ACCELERATION = double the value in the corresponding joint

OFFSET_AV_RATIO = 0.5|

Note

|

PlasmaC uses the LinuxCNC External Offsets feature for all Z axis motion, and for moving the X and/or Y axis for a consumable change while paused. For more information on this feature, please read External Axis Offsets in the LinuxCNC documentation. |

6.5.2. Axis GUI Specific

[PLASMAC] Section

FONT = sans 10 (valid font sizes are from 9 to 15 inclusive)

THEME = Clearlooks (any installed theme, only for the plasmaC tabs)

WINDOW_SIZE = 0 (0 = minimum size to suit font, 1 = maximised, width x height = custom size)

AXIS_ORIENT = portraitDefaults for the above parameters if they are not specified are:

FONT = sans 10

THEME = current system theme

WINDOW_SIZE = minimum size to suit font

AXIS_ORIENT = landscapeChanging the FONT size changes the minimum window size. PlasmaC requires a larger window size than the standard Axis window. Window size varies depending on whether the user has chosen to view the Run Panel as a Tab or a Panel on the right side of the GUI. If using portrait mode then window height will vary depending on whether or not the user has a rotary axis. If the window doesn’t completely fit on the screen then the user will need to reduce the font size.

Custom window size is specified as width x height e.g. 1600 x 900. Spaces are ignored but may be used for readability and x may be lower or upper case.

|

Note

|

WINDOW_SIZE has replaced MAXIMISED. For backwards compatibility these names are interchangeable. |

[DISPLAY] Section

TOOL_EDITOR = tooledit x y

USER_COMMAND_FILE = plasmac_axis.py.py

EMBED_TAB_NAME = Statistics

EMBED_TAB_COMMAND = gladevcp -c plasmac_stats -x <XID> -u ./plasmac/plasmac_stats.py -H ./plasmac/plasmac_stats.hal ./plasmac/plasmac_stats.glade

#use one of the next two

#run frame in tab behind preview

EMBED_TAB_NAME = Plasma Run

EMBED_TAB_COMMAND = gladevcp -c plasmac_run -x <XID> -u ./plasmac/plasmac_run.py -H ./plasmac/plasmac_run.hal ./plasmac/plasmac_run_tab.glade

#run frame in panel on right side

#GLADEVCP = -c plasmac_run -u ./plasmac/plasmac_run.py -H ./plasmac/plasmac_run.hal ./plasmac/plasmac_run_panel.glade

EMBED_TAB_NAME = Plasma Config

EMBED_TAB_COMMAND = gladevcp -c plasmac_config -x <XID> -u ./plasmac/plasmac_config.py -H ./plasmac/plasmac_config.hal ./plasmac/plasmac_config.glade

EMBED_TAB_NAME = Extras

EMBED_TAB_COMMAND = gladevcp -c plasmac_wizards -x {XID} -u ./plasmac/plasmac_wizards.py ./plasmac/plasmac_wizards.gladeThe Run Window can be displayed as either:

-

A panel on the right side of the Axis GUI which is suitable for widescreen displays.

-

A tab behind the Preview tab which is suitable for 4:3 ratio displays.

6.5.3. Gmoccapy GUI Specific

[DISPLAY] section

EMBED_TAB_NAME = plasmac_buttons

EMBED_TAB_LOCATION = box_cooling

EMBED_TAB_COMMAND = gladevcp -c plasmac_buttons -x <XID> -u ./plasmac/plasmac_buttons.py -H ./plasmac/plasmac_buttons.hal ./plasmac/plasmac_buttons.glade

EMBED_TAB_NAME = plasmac_control

EMBED_TAB_LOCATION = box_spindle

EMBED_TAB_COMMAND = gladevcp -c plasmac_control -x <XID> -u ./plasmac/plasmac_control.py -H ./plasmac/plasmac_control.hal ./plasmac/plasmac_control.glade

EMBED_TAB_NAME = Statistics

EMBED_TAB_LOCATION = ntb_preview

EMBED_TAB_COMMAND = gladevcp -c plasmac_stats -x <XID> -u ./plasmac/plasmac_stats.py -H ./plasmac/plasmac_stats.hal ./plasmac/plasmac_stats.glade

EMBED_TAB_NAME = Plasma Run

#use one of the next two

#run panel in tab behind preview

EMBED_TAB_LOCATION = ntb_preview

EMBED_TAB_COMMAND = gladevcp -c plasmac_run -x <XID> -u ./plasmac/plasmac_run.py -H ./plasmac/plasmac_run.hal ./plasmac/plasmac_run_tab.glade

#run panel in panel on left side

#EMBED_TAB_LOCATION = box_left

#EMBED_TAB_COMMAND = gladevcp -c plasmac_run -x <XID> -u ./plasmac/plasmac_run.py -H ./plasmac/plasmac_run.hal ./plasmac/plasmac_run_panel.glade

EMBED_TAB_NAME = Plasma Config

EMBED_TAB_LOCATION = ntb_preview

EMBED_TAB_COMMAND = gladevcp -c plasmac_config -x <XID> -u ./plasmac/plasmac_config.py -H ./plasmac/plasmac_config.hal ./plasmac/plasmac_config.glade

EMBED_TAB_NAME = plasmac_monitor

EMBED_TAB_LOCATION = box_tool_and_code_info

EMBED_TAB_COMMAND = gladevcp -c plasmac_monitor -x <XID> -u ./plasmac/plasmac_monitor.py -H ./plasmac/plasmac_monitor.hal ./plasmac/plasmac_monitor.glade

EMBED_TAB_NAME = Extras

EMBED_TAB_LOCATION = ntb_preview

EMBED_TAB_COMMAND = gladevcp -c plasmac_wizards -x {XID} -u ./plasmac/plasmac_wizards.py ./plasmac/plasmac_wizards.gladeThe Run Window can be displayed as either:

-

A panel on the left side of the Gmoccapy GUI which is suitable for widescreen displays.

-

A tab behind the Preview tab which is suitable for 4:3 ratio displays.

7. Using PlasmaC

Once PlasmaC is successfully installed, no Z axis motion is required to be part of the G-Code cut program. In fact, if any Z axis references are present in the cut program, the standard PlasmaC configuration will remove them during the program loading process.

For reliable use of PlasmaC the user should NOT use any Z axis offsets other than the coordinate system offsets (G54-G59.3).

Due to the way PlasmaC handles Z movements automatically, it is best to park the Z axis approximately 5mm (0.2") below the Z axis maximum limit (torch farthest away from the work piece) prior to performing any manual cuts or running any G-Code programs.

7.1. PlasmaC GUI Panels

PlasmaC makes several modifications to the GUI. Some additions are panels on permanent display and others are tabs behind the preview tab.

Some functions/features are only used for particular modes and are not displayed if they are not required by the chosen PlasmaC mode.

7.1.1. Config Panel

This panel is used to display configuration parameters that are modified infrequently.

It is possible to disable this panel so machine settings cannot be modified by unauthorized personnel. This is achieved by setting the following variable in the <machine_name>.ini file:

[PLASMAC] CONFIG_DISABLE = 1If it is necessary for authorized personnel to modify the configuration after disabling the Config Panel, A HAL pin named plasmac_config.config-disable can be set to 0 (zero) to enable the panel. This pin could be tied to a physical key-switch or similar on the cabinet so that only authorized personnel could enable the Config Panel to change settings.

Probing

Name |

Description |

Float Travel |

This sets the amount of travel the float switch moves before completing the float switch circuit. This distance can be measured by using the Probe Test button, and the method described in Initial Setup. |

Probe Speed |

This sets the speed at which the torch will probe to find the material after it moves to the Probe Height. |

Probe Height |

This sets the height above the Z axis minimum limit that Probe Speed begins. |

Ohmic Probe Offset |

This sets the distance above the material the torch will should go after a successful ohmic probe. It is mainly used to compensate for high probing speeds. |

Ohmic Retries |

This sets the number of times PlasmaC will retry a failed ohmic probe before falling back to the float switch for material detection. |

Skip IHS |

This sets the distance threshold used to determine if an Initial Height Sense (probe) can be skipped for the current cut, see IHS Skip. |

|

Note

|

If the amount of time between the torch contacting the material and when the torch moves up and comes to rest at the Pierce Height seems excessive, see the probing section for a possible solution. |

THC

Name |

Modes |

Description |

Delay |

0, 1, 2 |

This sets the delay (in seconds) measured from the time the Arc OK signal is received until Torch Height Controller (THC) activates. |

Threshold (V) |

0, 1, 2 |

This sets the voltage variation allowed from the target voltage before for THC makes movements to correct the torch height. |

PID P Gain (Speed) |

0, 1 |

This sets the Proportional gain for the THC PID loop. This roughly equates to how quickly the THC attempts to correct changes in height. |

VAD Threshold (%) |

0, 1 |

(Velocity Anti Dive) This sets the percentage of the current cut feed rate the machine can slow to before locking the THC to prevent torch dive. |

Void Sense Override (%) |

0, 1 |

This sets the size of the change in cut voltage necessary to lock the THC to prevent torch dive (higher values need greater voltage change to lock THC). |

PID I Gain |

0, 1 |

This sets the Integral gain for the THC PID loop. Integral gain is associated with the sum of errors in the system over time and is not always needed. |

PID D Gain |

0, 1 |

This sets the Derivative gain for the THC PID loop. Derivative gain works to dampen the system and reduce over correction oscillations and is not always needed. |

|

Note

|

PID loop tuning is a complicated process and is outside the scope of this User Guide. There are many sources of information available to assist with understanding and tuning PID loops. If the THC is not making corrections fast enough, it is recommended to increase the P gain in small increments until the system operates favorably. Large P gain adjustments can result in over correction and oscillations. |

Safety

Name |

Description |

Safe Height |

This sets the height above the material that the torch will retract to before executing rapid moves. |

Arc

Name |

Modes |

Description |

Fail Timeout |

0, 1, 2 |

This sets the amount of time (in seconds) PlasmaC will wait between commanding a "Torch On" and receiving an Arc OK signal before timing out and displaying an error message. |

Max. Starts |

0, 1, 2 |

This sets the number of times PlasmaC will attempt to start the arc. |

Retry Delay |

0, 1, 2 |

This sets the time (in seconds) between an arc failure and another arc start attempt. |

Voltage Scale |

0, 1 |

This sets the arc voltage input scale and is used to display the correct arc voltage. |

Voltage Offset |

0, 1 |

This sets the arc voltage offset and is used to display zero volts when there is zero arc voltage input. |

Height Per Volt |

0, 1, 2 |

This sets the distance the torch would need to move to change the arc voltage by one volt. |

OK High Volts |

0 |

This sets the voltage threshold below which Arc OK signal is valid. |

OK Low Volts |

0 |

This sets the voltage threshold above which the Arc OK signal is valid. |

|

Note

|

When setting the OK Low Volts and OK High Volts in Mode 0, the cut voltage of a stable arc must be greater than the OK Low Volts value but lower than the OK High Volts value for PlasmaC to receive a valid Arc OK signal. To further clarify, to have a valid Arc OK, the arc voltage must fall between the two limits. |

Motion

Name |

Description |

Max. Speed |

Displays the maximum velocity the Z axis is capable of (this is controlled by the <machine_name>.ini file). |

Setup Speed |

The Z axis velocity for setup moves (movements to Probe Height, Pierce Height, Cut Height, etc). |

|

Note

|

Setup Speed has no effect on THC speed which is capable of the velocity displayed in the Max. Speed field. |

Scribe

Name |

Description |

Arm Delay |

This sets the delay (in seconds) from the time the scribe command is received to the activation of the scribe. This allows the scribe to reach surface of the material before activating the scribe. |

On Delay |

This sets the delay (in seconds) to allow the scribe mechanism to start before beginning motion. |

Spotting

Name |

Description |

Threshold (V) |

This sets the arc voltage at which the delay timer will begin. |

Time On (mS) |

This sets the length of time (in milliseconds) the torch is on after threshold voltage is reached. |

Save & Reload Buttons

The Save button will save the currently displayed parameters to the <machine_name>_config.cfg file.

The Reload button will reload all the parameters from the <machine_name>_config.cfg file.

The Version label displays the current PlasmaC version.

The Backup button will create a complete machine configuration backup for archiving or to aid in fault diagnosis. A compressed backup of the machine configuration will be saved in the user’s Linux home directory. The file name will be <machine_name>_<version_info>.tar.gz where <machine_name> is the machine name entered in the configurator, and <version_info> is the current PlasmaC version the user is on.

7.1.2. Run Panel

This panel shows the parameters which are active for the current cut.

There are two formats for this panel, a tab that sits behind the preview tab or a panel at the right side of the GUI. The formats are different but both provide the same functionality for controlling cut parameters.

See Axis [DISPLAY] Section or Gmoccapy [DISPLAY] section for information on how to change between the two formats in the <machine_name>.ini files. Alternatively, the user could run the configurator again to select a different option.

Cut Parameters

Name |

Description |

Material |

The top drop down menu is used to manually select the current material cut parameters. If there are no materials in the material file then only the default material will be displayed. |

Kerf Width |

This sets the kerf width for the currently selected material. |

THC Enabled |

This check box enables or disables the THC for the currently selected material. |

Pierce Height |

This sets the pierce height for the currently selected material. |

Pierce Delay |

This sets the pierce delay (in seconds) for the currently selected material. |

Cut Height |

This sets the cut height for the currently selected material. |

Cut Feed Rate |

This sets the cut feed rate for the currently selected material. |

Cut Amps |

This sets the cut amperage for the currently selected material. |

Cut Volts |

This sets the cut voltage for the currently selected material. |

P-Jump Height |

This sets the Puddle Jump height for the currently selected material. |

P-Jump Delay |

This sets the Puddle Jump delay (in seconds) for the currently selected material. |

Pause At End |

This sets the amount of time (in seconds) the torch will stay on at the end of the cut before proceeding with the M5 command to turn off and raise the torch. For more information see Pause At End Of Cut. |

Gas Pressure |

This sets the gas pressure for the currently selected material. |

Cut Mode |

This sets the cut mode for the currently selected material. |

THC

Name |

Modes |

Description |

State |

0, 1, 2 |

Disabled = The THC is permanently off. |

Use Auto Volts |

0, 1 |

Checked = The THC target voltage is ascertained by sampling the arc voltage after the THC Delay has expired. |

Velocity Anti Dive Enable (VAD) |

0, 1, 2 |

Checked = Velocity Anti-Dive is enabled. |

Void Sense Enable |

0, 1 |

Checked = Void sensing is enabled. |

Ohmic Probe

Name |

Description |

Ohmic Probe Enable |

This check box enables or disables the ohmic probe input. |

|

Note

|

If the Ohmic Probe input is disabled, the Ohmic Probe LED will still show the status of the probe input, but the Ohmic Probe results will be ignored. |

Single Cut

Name |

Description |

X Axis Length |

This sets the X axis distance to travel for a single cut. |

Y Axis Length |

This sets the Y axis distance to travel for a single cut. |

Start Cut Button |

Press this button to commence a single cut. |

Cutting Mode

Name |

Description |

Mesh Mode |

This check box will enable or disable mesh mode for the cutting of expanded metal. This check box may be enabled or disabled at any time during normal cutting. Additionally this mode may be enabled or disabled via proper M codes in a running program. |

Ignore Arc OK |

This check box will determine if PlasmaC ignores the Arc OK signal. This check box may be enabled or disabled at any time during normal cutting. Additionally this mode may be enabled or disabled via proper M codes in a running program. |

PowerMax Comms

|

Note

|

This frame is only visible if a PM_PORT is configured in the [PLASMAC] section of the <machine_name>.ini file. |

Name |

Description |

Enable |

This check box will enable or disable the communications to a PowerMax. |

Status |

When PowerMax communications are enabled, this will display one of the following: |

For more information, see the PowerMax Communications section.

Run Settings

Name |

Description |

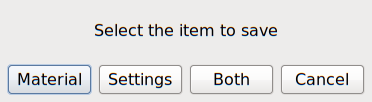

Save |

This button will bring up a dialog box with the following options: |

Reload |

This button will reload all of the displayed settings in the Run Panel, and will re-display the currently selected material. Regardless of the previously saved settings, if PowerMax communications are enabled before pressing Reload, they will remain enabled after. |

New |

This button will allow a new material to be added to the material file. The user will be prompted for a material number and a material name, all other parameters will be read from the currently selected material. Once entered, PlasmaC will reload the material file and display the new material. The Cut Parameters for the new material will then need to be adjusted and saved. |

Delete |

This button is used to delete a material. After pressing it, the user will be prompted for a material number to be deleted, and prompted again to ensure the user is sure. After deletion, the material file will be reloaded and the drop down list will display the default material. |

An example of the Save dialog box is below:

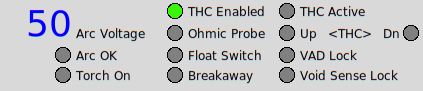

7.1.3. Monitor Panel

The Monitor Panel is used to display the status of various relevant I/O’s. Both Axis and Gmoccapy have similar Monitor Panels.

Name |

Modes |

Description |

Arc Voltage |

0, 1 |

Displays the actual arc voltage. |

Arc OK |

1, 2 |

Indicates the status of the Arc OK signal. |

Torch On |

0, 1, 2 |

Indicates the status of the Torch On output signal. |

THC Enabled |

0, 1, 2 |

Indicates whether the THC will be enabled or disabled during a cut. |

Ohmic Probe |

0, 1, 2 |

Indicates that the probe has sensed the material. |

Float Switch |

0, 1, 2 |

Indicates that the float switch is activated. |

Breakaway |

0, 1, 2 |

Indicates that the torch breakaway sensor is activated. |

THC Active |

0, 1, 2 |

Indicates that the THC is actively controlling the Z axis. |

THC Up |

0, 1, 2 |

Indicates that the THC is commanding the Z axis to raise. |

THC Down |

0, 1, 2 |

Indicates that the THC is commanding the Z axis to lower. |

VAD Lock |

0, 1, 2 |

Indicates that the THC is locked at the current height due to the cut velocity falling below the VAD Threshold percentage set in the Config Panel. |

Void Sense Lock |

0, 1 |

Indicates that the THC is locked due to a void being sensed. |

|

Note

|

The Ohmic Probe LED will show the status of the probe input regardless of whether Ohmic Probe is enabled or disabled. |

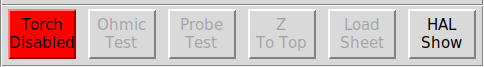

7.1.4. Button Panel

The Button Panel contains buttons useful for the operation of the machine.

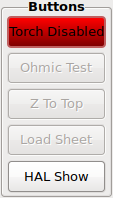

Both GUIs have a Torch Enable button which is permanent, all other buttons are user programmable in the <machine_name>.ini file. Axis has five user buttons and Gmoccapy has four user buttons.

Axis button layout:

Gmoccapy button layout:

The Torch Disable/Enable button toggles between Enabling and Disabling the torch. This button defaults to "Torch Disabled" when PlasmaC is first run, and must be clicked to change it to "Torch Enabled" before material cutting can commence.

If "Torch Disabled" is displayed by this button, then running a loaded program will cause the machine to run the cycle without firing the torch. This is sometimes referred to as a "dry run".

7.1.5. Control Panel

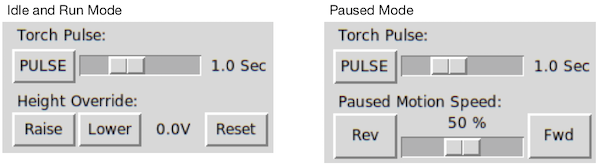

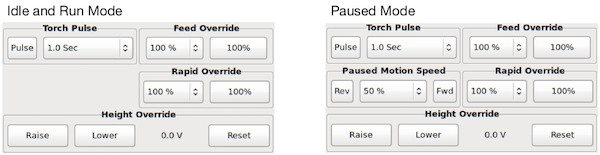

The Control Panel allows the user to pulse the torch for a desired period of time, manually override the height control, and manipulate the machine during paused motion at a desired speed. Both Axis and Gmoccapy are similar except the Gmoccapy Control Panel is integrated into the existing frame containing feed and rapid overrides.

Once the machine is homed, Torch Pulse and Height Override are shown permanently in Idle and Run Modes. Paused Motion Speed will be enabled if the machine enters Paused Mode. Examples of the different states are shown below.

Axis Control Panel:

Gmoccapy Control Panel:

Torch Pulse

Name |

Description |

Pulse |

This button will pulse the torch. |

Pulse Time Slider |

This slider will set the amount of time (in seconds) that the torch remains on when pulsed. |

Height Override

Name |

Description |

Raise |

Each press of this button will raise the height of the torch by the value set by the Height Per Volt field in the Arc frame of the Config Panel. |

Lower |

Each press of this button will lower the height of the torch by the value set by the Height Per Volt field in the Arc frame of the Config Panel. |

Reset |

This button will cancel any manual height override. |

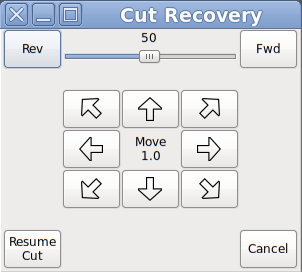

Paused Motion Speed

In the event of a paused program, this interface allows X/Y motion to follow the programmed path in the reverse or forward direction.

Name |

Description |

Rev |

In the event of a paused program, this button will move the machine in reverse along the programmed path until it reaches the last M3 command that was either executed or that PlasmaC was attempting to execute before the program became paused. |

Motion Speed Slider |

This slider will set the percentage of the current Cut Feed Rate shown in the Run Panel’s Cut Parameters section for the currently selected material. |

Fwd |

In the event of a paused program, this button will move the machine forward along the programmed path indefinitely until the program’s end, skipping over M3 commands. |

For advanced recovery from a failed cut see cut recovery.

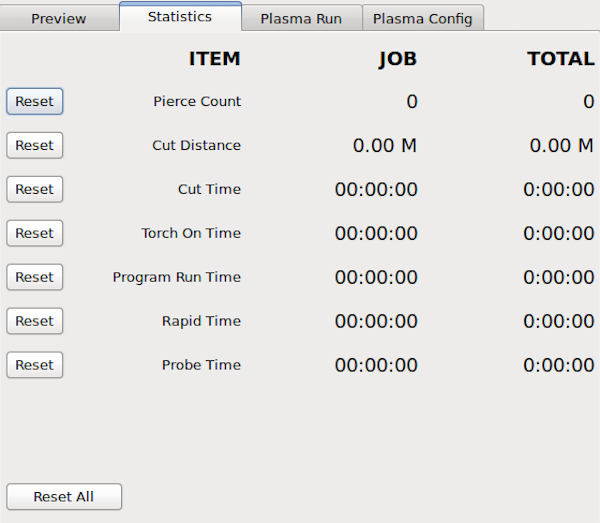

7.1.6. Statistics Panel

The Statistics Panel provides statistics to allow for the tracking of consumable wear and job run times.

These statistics are shown for the current job as well as the running total.

Previous job statistics are reset once the next program is run.

The total values may be reset either individually by clicking the corresponding "Reset" button, or they may all be reset together by clicking "Reset All".

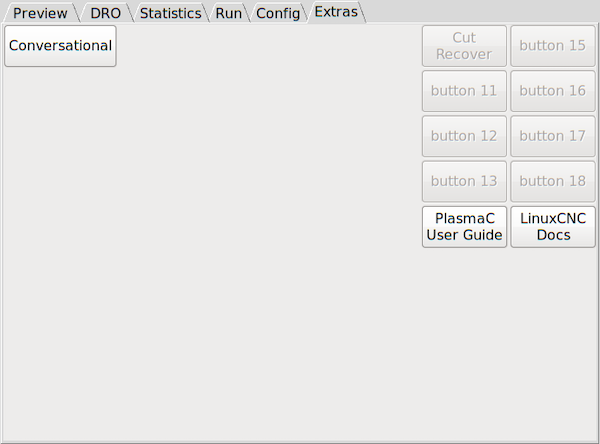

7.1.7. Extras Panel

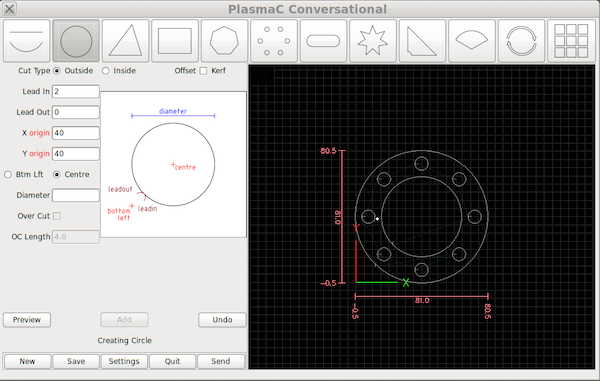

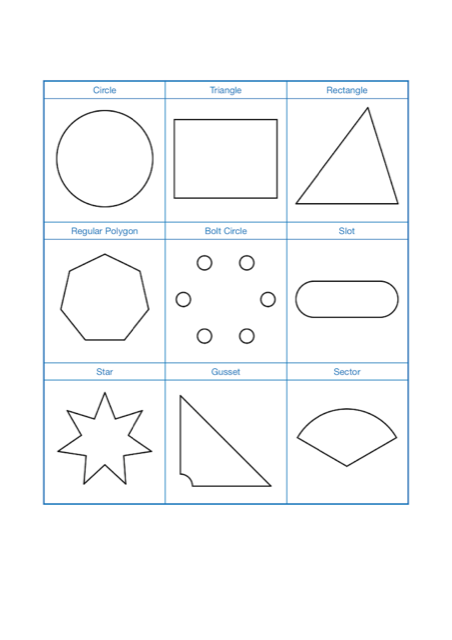

The Extras Panel provides ten additional user-customizable buttons plus a button to bring up the Conversational dialog box. The Conversational shapes library enables the user to quickly program various simple shapes for quick cutting without the need for CAM software.

See conversational shape library for detailed information on the Conversational feature.

See custom user buttons for detailed information on custom user buttons.

The Extras panel may be disabled by making the appropriate edits in the [DISPLAY] section of the <machine_name>.ini file. This will have no effect on the operation of the PlasmaC software.

To disable the Extras Panel, change:

EMBED_TAB_NAME = Extras

EMBED_TAB_COMMAND = gladevcp -c plasmac_wizards -x {XID} -u ./plasmac/plasmac_wizards.py ./plasmac/plasmac_wizards.gladeTo:

#EMBED_TAB_NAME = Extras

#EMBED_TAB_COMMAND = gladevcp -c plasmac_wizards -x {XID} -u ./plasmac/plasmac_wizards.py ./plasmac/plasmac_wizards.glade7.2. Mandatory Codes

Aside from the preamble code, postamble code, and X/Y motion code, the only mandatory G-Code syntax for PlasmaC to run a G-Code program is M3 $0 S1 to begin a cut and M5 $0 to end a cut.

If the user is using PlasmaC without multiple tools enabled then it is permissible to use M3 S1 in lieu of M3 $0 S1 to begin a cutting job and M5 in lieu of M5 $0.

7.3. Coordinates

See recommended Z axis settings.

Each time LinuxCNC (PlasmaC) is started Joint homing is required. This allows LinuxCNC (PlasmaC) to establish the known coordinates of each axis and set the soft limits to the values specified in the <machine_name>.ini file in order to prevent the machine from crashing into a hard stop during normal use.

If the machine does not have home switches then the user needs to ensure that all axes are at the home coordinates specified in the <machine_name>.ini file before homing.

If the machine has home switches then it will move to the specified home coordinates when the Joints are homed.

Depending on the machine’s configuration there will either be a Home All button or each axis will need to be homed individually. Use the appropriate button/buttons to home the machine.

As mentioned in the Initial Setup section, it is recommended that the first time PlasmaC is used that the user ensure there is nothing below the torch then jog the Z axis down until it stops at the Z axis MINIMUM_LIMIT then click Touch Off with the Z axis selected to set the Z axis at zero offset. This should not need to be done again.

Before starting a program, jog the Z axis up to approximately 5mm (0.196") from the top of travel (Z Axis MAXIMUM_LIMIT). Leave the Z axis at this position as PlasmaC will control all Z axis motion while running a program, and park the Z Axis in this position when the program completes.

If the user intends to place the material in the exact same place on the table every time, the user could jog the X and Y axes to the machine to the corresponding X0 Y0 position as established by the CAM software and then Touch Off both axes with a zero offset.

If the user intends to place the material randomly on the table then the user must Touch Off the X and Y axes at the appropriate position before starting the program.

7.4. Path Tolerance

The provided RS274NGC_STARTUP_CODE files: metric_startup.ngc and imperial_startup.ngc set the motion blending path tolerance with a G64 command P value to 0.1mm and 0.004" respectively. The P value corresponds to the amount the actual cut path followed by the machine may deviated from the programmed cut path before reducing velocity. If LinuxCNC (PlasmaC) receives an E-stop signal at any stage, the path tolerance will be set to the default (no P value) which will maintain the best possible speed and round corners off as a result. To prevent this, it is recommended that the path tolerance is set by placing the appropriate G64 command and P value in the header of each G-Code file.

For Metric:

G64 P0.1For Imperial:

G64 P0.0047.5. Paused Motion

PlasmaC has the ability to allow the repositioning of the X and Y axes along the current cut path while the G-Code program is paused.

In order to use this feature, LinuxCNC’s Adaptive Feed Control (M52) must be turned on (P1).

To enable Paused Motion The preamble of the G-Code must contain the following line:

M52 P1To turn off Paused Motion at any point, use the following command:

M52 P07.6. Pause At End Of Cut

This feature can be used to allow the arc to "catch up" to the torch position to fully finish the cut. It is usually required for thicker materials and is especially useful when cutting stainless steel.

Using this feature will cause all motion to pause at the end of the cut while the torch is still on. After the dwell time (in seconds) set by the Pause At End parameter in the Cut Parameters section of the Run Panel has expired, PlasmaC will proceed with the M5 command to turn off and raise the torch.

7.7. Multiple Tools

PlasmaC has the ability to allow the use of more than one tool when running a cut program. Multiple tools must be enabled in PlasmaC before they can be used. Valid tools are:

-

Plasma Torch - Used for normal Plasma cutting.

-

Scribe - Used for material engraving.

-

Plasma Torch - Used for spotting (creating dimples to aid in drilling).

If multiple tools are enabled then a LinuxCNC tool number (designated by $n) is required to be in the M3 command to select the correct tool to be used. Examples:

-

M3 $0 S1 will select and start the plasma cutting tool.

-

M3 $1 S1 will select and start the scribe.

-

M3 $2 S1 will select and the plasma spotting tool.

To enable the multiple tools feature the user will need to edit the following line in the <machine_name>_connections.hal file.

from:

setp plasmac.multi-tool 0to:

setp plasmac.multi-tool 1In order to use multiple tools with a scribe, it is necessary for the user to add the X and Y axis offsets to the LinuxCNC tool table. The tool.tbl file is found in the <machine_name> config folder. Tool 0 is assigned to the Plasma Torch and Tool 1 is assigned to the scribe. Tools are selected with a Tn M6 command, and then a G43 H0 command is required to apply the offsets for the selected tool. It is important to note that the LinuxCNC tool table and tool commands only come into play if the user is using a scribe in addition to a plasma torch. For more information, see scribe.

7.8. Velocity Reduction

There is a HAL pin available named motion.analog-out-03 that can be changed in G-Code with the M67 (Synchronized with Motion)/M68 (Immediate) commands. This pin will reduce the velocity to the percentage specified in the command.

It is important to thoroughly understand the difference between Synchronized with Motion and Immediate:

-

M67 (Synchronized with Motion) - The actual change of the specified output (P2 (THC) for example) will happen at the beginning of the next motion command. If there is no subsequent motion command, the output changes will not occur. It is best practice to program a motion code (G0 or G1 for example) right after a M67.

-

M68 (Immediate) - These commands happen immediately as they are received by the motion controller. Since these are not synchronized with motion, they will break blending. This means if these codes are used in the middle of active motion codes, the motion will pause to activate these commands.

Examples:

-

M67 E3 Q0 would set the velocity to 100% of CutFeedRate.

-

M67 E3 Q40 would set the velocity to 40% of CutFeedRate.

-

M67 E3 Q60 would set the velocity to 60% of CutFeedRate.

-

M67 E3 Q100 would set the velocity to 100% of CutFeedRate.

The minimum percentage allowed is 10%, values below this will be set to 10%.

The maximum percentage allowed is 100%, values above this will be set to 100%.

If the user intends to use this feature it would be prudent to add M68 E3 Q0 to both the preamble and postamble of the G-Code program so the machine starts and ends in a known state.

|

Tip

|

Another way of achieving the same result is to use F#<_hal[plasmac.cut-feed-rate] with a multiplier. |

For example:

F[#<_hal[plasmac.cut-feed-rate] * 0.6]|

Important

|

G-CODE THC AND VELOCITY BASED THC ARE NOT ABLE TO BE USED IF CUTTER COMPENSATION IS IN EFFECT; AN ERROR MESSAGE WILL BE DISPLAYED. |

|

Warning

|

If Cut Feed Rate in the Run Panel is set to Zero then PlasmaC will use motion.requested-velocity (as set by a standard Feedrate call in the G-Code) for the THC calculations. This is not recommended as it is not a reliable way of implementing velocity based THC. |

|

Note

|

All references to CutFeedRate refer to the Cut Feed Rate value displayed in the Run Panel. |

7.9. Material Handling

Material handling uses a material file that was created for the machine configuration when the configurator was ran and allows the user to conveniently store known material settings for easy recall either manually or automatically via G Code. The resulting material file is named <machine_name>_material.cfg.

PlasmaC does not require the use of a material file. Instead, the user could change the cut parameters manually from the Run Panel. It is also not required to use the automatic material changes. If the user does not wish to use this feature they can simply omit the material change codes from the G-Code file.

7.9.1. Material File

Material numbers in the materials file do not need to be consecutive nor do they need to be in numerical order.

The following variables are mandatory and an error message will appear if any are not found when the material file is loaded.

-

PIERCE_HEIGHT

-

PIERCE_DELAY

-

CUT_HEIGHT

-

CUT_SPEED

The following variables are optional. If they are not detected or have no value assigned, they will be assigned a value of 0 and no error message will appear.

-

NAME

-

KERF_WIDTH

-

THC

-

PUDDLE_JUMP_HEIGHT

-

PUDDLE_JUMP_DELAY

-

CUT_AMPS

-

CUT_VOLTS

-

PAUSE_AT_END

-

GAS_PRESSURE

-

CUT_MODE

|

Warning

|

It is the responsibility of the operator to ensure that the variables are included if they are a requirement for the G-Code to be run. |

The material file uses the following format:

[MATERIAL_NUMBER_1]

NAME = name

KERF_WIDTH = value

THC = value (0 = off, 1 = on)

PIERCE_HEIGHT = value

PIERCE_DELAY = value

PUDDLE_JUMP_HEIGHT = value

PUDDLE_JUMP_DELAY = value

CUT_HEIGHT = value

CUT_SPEED = value

CUT_AMPS = value (for info only unless PowerMax communications is enabled)

CUT_VOLTS = value (modes 0 & 1 only, if not using auto voltage sampling)

PAUSE_AT_END = value

GAS_PRESSURE = value (only used for PowerMax communications)

CUT_MODE = value (only used for PowerMax communications)It is possible to add new material, delete material, or edit existing material from the Run Panel. It is also possible to achieve this by using magic comments in a g-Code file.

The material file may be edited with a text editor while LinuxCNC is running. After any changes have been saved, press Reload in the Run Panel to reload the material file.

7.9.2. Manual Material Handling

For manual material handling, the user would manually select the material from the materials list in the Run Panel before starting the G-Code program. In addition to selecting materials with materials list in the Run Panel, the user could use the MDI to change materials with the following command:

M190 PnThe following code is the minimum code necessary to have a successful cut using the manual material selection method:

F#<_hal[plasmac.cut-feed-rate]>

M3 $0 S1

.

.

M5 $0|

Note

|

Manual material handling will restrict the user to only one material for the entire job. |

7.9.3. Automatic Material Handling

For automatic material handling, the user would add commands to their G-Code file which will enable PlasmaC to change the material automatically.

The following codes may be used to allow PlasmaC to automatically change materials:

-

M190 Pn - Changes the currently displayed material to material number n.

-

M66 P3 L3 Q1 - Adds a small delay (1 second in this example) to wait for PlasmaC to confirm that it successfully changed materials.

-

F#<_hal[plasmac.cut-feed-rate]> - Sets the cut feed rate to the feed rate shown in the Cut Parameter section of the Run Panel.

For automatic material handling, the codes MUST be applied in the order shown. If a G-Code program is loaded which contains one or more material change commands then the first material will be displayed in the Run Panel as the program is loading. The following code is the minimum code necessary to have a successful cut using the automatic material selection method:

M190 Pn

M66 P3 L3 Q1

F#<_hal[plasmac.cut-feed-rate]>

M3 $0 S1

.

.

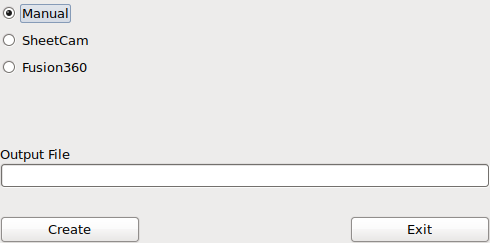

M5 $07.9.4. Materialverter

This application is used to convert existing tool tables into PlasmaC material files. It can also create a material file from manual user input to entry fields.

At this stage the only conversions available are to tool tables from SheetCam and Fusion360.

SheetCam tool tables are complete and the conversion is fully automatic. The SheetCam tool file must be in the SheetCam .tools format.

Fusion360 tool tables do not have all of the required fields so the user will be prompted for missing parameters. The Fusion360 tool file must be in the Fusion360 .json format.

If the user has a format from a different CAM software they would like converted, create a New Topic in the PlasmaC forum section of the LinuxCNC forum to request this addition.

Materialverter may be run from a GUI file manager by double clicking on materialverter.py in the user’s configuration directory or may be run by entering the following command into a terminal window:

python ~/linuxcnc/configs/<machine_name>/materialverter.pyThis will bring up the Materialverter dialog:

Select one of:

-

Manual - to manually create a new material file.

-

SheetCam - to convert a SheetCam tool file.

-

Fusion360 - to convert a Fusion360 tool file.

For SheetCam only, select whether the user requires a metric or imperial output file.

To convert:

-

Select the Input File to be converted.

-

Select the Output File to write to. This would normally be ~/linuxcnc/configs/<machine_name>_material.cfg. If necessary, the user could select a different file and hand edit the <machine_name>_material.cfg file.

-

Click Create/Convert and the new material file will be created.

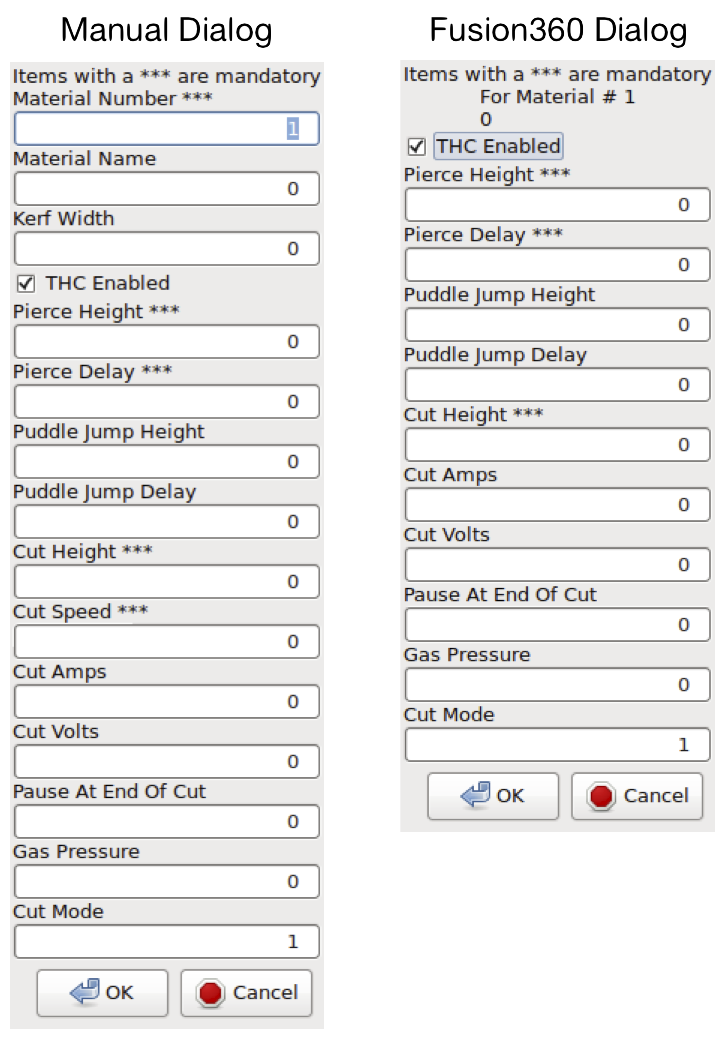

For both a Manual creation or a Fusion360 conversion, a dialog will show with all available parameters displayed for input. Any entry marked with *** is mandatory and all other entries are optional depending on the user’s configuration needs.

|

Note

|

If the user selects ~/linuxcnc/configs/<machine_name>_material.cfg and the file already exists, it will be overwritten. |

7.9.5. Materials Adding And Editing Via G-Code

It is possible to add new materials or edit existing materials by using "magic comments" in a G-Code file.

Formatting rules are:

-

The entire comment must be in parentheses.

-

The beginning of the magic comment must be: (o=

-

The equals sign must immediately follow each parameter with no space.

-

The mandatory parameters must be in the magic comment (nu and na are not required for option 0).

-

There can be any number and type of magic comments in a G-Code file with the exception of option 0. If more than one option 0 comment is found in the G-Code file then only the last one found will be used.

-

If option 0 is to be used in addition to option 1 and/or option 2 then the option 0 comment must be the last one in the G-Code file.

The options are:

Option |

Description |

0 |

Creates a temporary default material. |

1 |

Adds a new material if the number specified does not exist. |

2 |

Overwrites an existing material if the number specified exists. |

Mandatory parameters are:

Name |

Description |

o |

Selects the option to be used. |

nu |

Sets the material number (not required for option 0). |

na |

Sets the material name (not required for option 0). |

ph |

Sets the pierce height. |

pd |

Sets the pierce delay. |

ch |

Sets the cut height. |

fr |

Sets the feed rate. |

Optional parameters are:

Name |

Description |

kw |

Sets the kerf width. |

th |

Sets the THC status (0=disabled, 1=enabled). |

ca |

Sets the cut amps. |

cv |

Sets the cut voltage. |

pe |

Sets the pause at end delay. |

gp |

Sets the gas pressure (PowerMax). |

cm |

Sets the cut mode (PowerMax). |

jh |

Sets the puddle jump height. |

jd |

Sets the puddle jump delay. |

A complete example:

(o=1, nu=2, na=5mm Mild Steel 40A, ph=3.1, pd=0.1, ch=0.75, fr=3000, kw=0.5, th=1, ca=45, cv=110, pe=0.1, gp=5, cm=1, jh=0, jd=0)7.10. THC (Torch Height Controller)

The THC can be controlled from the THC frame of the Run Panel.

The THC can also be enabled or disabled directly from the G-Code program provided that THC is not disabled in the THC section of the Run Panel.

PlasmaC uses a control voltage which is dependent on the state of the Use Auto Volts checkbox in the Run Panel:

-

If Use Auto Volts is checked then the actual cut voltage is sampled after the cut begins. To allow the arc voltage to stabilize, PlasmaC waits for the amount of time displayed in the Delay field of the THC section of the config panel before sampling the voltage. The sampled voltage is then used as the target voltage to adjust the height of the torch.

-

If Use Auto Volts is not checked then the voltage displayed as Cut Volts in the Cut Parameters section of the Run Panel is used as the target voltage to adjust the height of the torch.

The THC does not become active until the velocity reaches 99.9% of the CutFeedRate.

G-Code THC

THC may be disabled and enabled directly from G-Code, provided the THC is not disabled in the Run Panel, by setting or resetting the motion.digital-out-02 pin with the M-Codes M62-M65:

-

M62 P2 will disable THC (Synchronized with Motion)

-

M63 P2 will enable THC (Synchronized with Motion)

-

M64 P2 will disable THC (Immediately)

-

M65 P2 will enable THC (Immediately)

It is important to thoroughly understand the difference between Synchronized with Motion and Immediate:

-

M62 and M63 (Synchronized with Motion) - The actual change of the specified output (P2 (THC) for example) will happen at the beginning of the next motion command. If there is no subsequent motion command, the output changes will not occur. It is best practice to program a motion code (G0 or G1 for example) right after a M62 or M63.

-

M64 and M65 (Immediate) - These commands happen immediately as they are received by the motion controller. Since these are not synchronized with motion, they will break blending. This means if these codes are used in the middle of active motion codes, the motion will pause to activate these commands.

Velocity Based THC

If the cut velocity falls below a percentage of CutFeedRate (as defined by the VAD Threshold % value in the THC frame of the Config Panel) the THC will be locked until the cut velocity returns to at least 99.9% of CutFeedRate. This will be made apparent by the THC Velocity Lock indicator illuminating in the Monitor Panel.

Velocity based THC prevents the torch height being changed when velocity is reduced for a sharp corner or a small hole.

It is important to note that Velocity Reduction affects the Velocity Based THC in the following ways:

-

If Velocity Reduction is invoked in the middle of the cut, the THC will be locked.

-

The THC will remain locked until the velocity reduction is canceled by returning it to a value that is above the VAD Threshold, and the torch actually reaches 99.9% of the CutFeedRate.

7.11. Cutter Compensation

LinuxCNC (PlasmaC) has the ability to automatically adjust the cut path of the current program by the amount specified in Kerf Width of the selected material’s Cut Parameters. This is helpful if the G-Code is programmed to the nominal cut path and the user will be running the program on different thickness materials to help ensure consistently sized parts.

To use cutter compensation the user will need to use G41.1, G42.1 and G40 with the kerf width HAL pin:

-

G41.1 D#<_hal[plasmac_run.kerf-width-f]> : offsets torch to the left of the programmed path

-

G42.1 D#<_hal[plasmac_run.kerf-width-f]> : offsets torch to the right of the programmed path

-

G40 turns the cutter compensation off

|

Important

|

IF CUTTER COMPENSATION IS IN EFFECT G-CODE THC, VELOCITY BASED THC AND OVERCUT ARE NOT ABLE TO BE USED; AN ERROR MESSAGE WILL BE DISPLAYED. |

7.12. Initial Height Sense (IHS) Skip

IHS may be skipped in one of two different ways:

-

If the THC is disabled then the IHS skip will occur if the start of the cut is less than Skip IHS distance from the last successful probe.

-

If the THC is enabled then the IHS skip will occur if the start of the cut is less than Skip IHS distance from the end of the last cut.

A value of zero for Skip IHS will disable IHS skipping.

Any errors encountered during a cut will disable IHS skipping for the next cut if Skip IHS is enabled.

7.13. Probing

Probing may be done with either ohmic sensing or a float switch. It is also possible to combine the two methods, in which case the float switch will provide a fallback to ohmic probing.

If the machine’s torch does not support ohmic probing, the user could have a separate probe next to the torch. In this case the user would extend the probe below the torch. The probe must NOT extend more than the minimum Cut Height below the torch and the Z axis offset distance needs to be entered as the ohmic-probe-offset in the Config Panel.

Probing setup is done in the Probing frame of the Config Panel. Probing speed is controlled in the Motion frame of the Config Panel.