1. Introduction

You have seen how handy a tool length offset can be. Having this allows the programmer to ignore the actual tool length when writing a part program. In the same way, it is really nice to be able to find a prominent part of a casting or block of material and work a program from that point rather than having to take account of the location at which the casting or block will be held during the machining.

This chapter introduces you to offsets as they are used by the LinuxCNC. These include;

-

machine coordinates (G53)

-

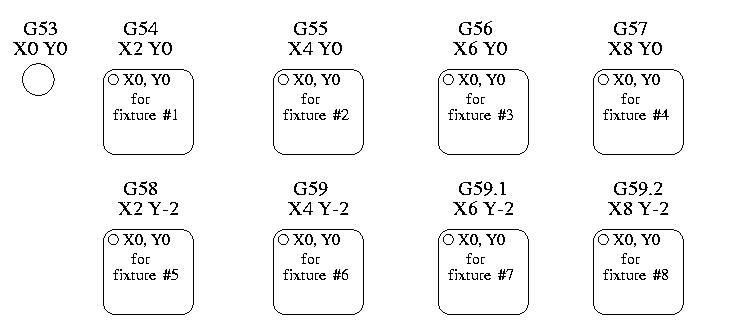

nine fixture offsets (G54-G59.3)

-

global offsets (G92)

2. The Machine Position Command (G53)

Regardless of any offsets that may be in effect, putting a G53 in a block of code tells the interpreter to go to the real or absolute axis positions commanded in the block. For example

G53 G0 X0 Y0 Z0

will get you to the actual position where these three axes are zero. You might use a command like this if you have a favorite position for tool changes or if your machine has an auto tool changer. You might also use this command to get the tool out of the way so that you can rotate or change a part in a vice.

G53 is not a modal command. It must be used on each line where motion based upon absolute machine position is desired.

3. Fixture Offsets (G54-G59.3)

Work or fixture offset are used to make a part home that is different from the absolute, machine coordinate system. This allows the part programmer to set up home positions for multiple parts. A typical operation that uses fixture offsets would be to mill multiple copies of parts on multiple part holders or vises.

The values for offsets are stored in the VAR file that is requested by the INI file during the startup of an LinuxCNC. In our example below we’ll use G55. The values for each axis for G55 are stored as variable numbers.

| Variable | Value |

|---|---|

5241 |

0.000000 |

5242 |

0.000000 |

5243 |

0.000000 |

5244 |

0.000000 |

5245 |

0.000000 |

5246 |

0.000000 |

In the VAR file scheme, the first variable number stores the X offset, the second the Y offset and so on for all six axes. There are numbered sets like this for each of the fixture offsets.

Each of the graphical interfaces has a way to set values for these offsets. You can also set these values by editing the VAR file itself and then restarting LinuxCNC so that the LinuxCNC reads the new values however this is not the recommended way. G10, G92, G28.1, etc are better ways to affect variables. For our example let’s directly edit the file so that G55 takes on the following values.

| Variable | Value |

|---|---|

5241 |

2.000000 |

5242 |

1.000000 |

5243 |

-2.000000 |

5244 |

0.000000 |

5245 |

0.000000 |

5246 |

0.000000 |

You should read this as moving the zero positions of G55 to X = 2 units, Y= 1 unit, and Z = -2 units away from the absolute zero position.

Once there are values assigned, a call to G55 in a program block would shift the zero reference by the values stored. The following line would then move each axis to the new zero position. Unlike G53, G54 through G59.3 are modal commands. They will act on all blocks of code after one of them has been set. The program that might be run using fixture offsets would require only a single coordinate reference for each of the locations and all of the work to be done there. The following code is offered as an example of making a square using the G55 offsets that we set above.

G55 G0 X0 Y0 Z0 G1 F2 Z-0.2000 X1 Y1 X0 Y0 G0 Z0 G54 X0 Y0 Z0 M2

But, you say, why is there a G54 in there near the end. Many programmers leave the G54 coordinate system with all zero values so that there is a modal code for the absolute machine based axis positions. This program assumes that we have done that and use the ending command as a command to machine zero. It would have been possible to use g53 and arrive at the same place but that command would not have been modal and any commands issued after it would have returned to using the G55 offsets because that coordinate system would still be in effect.

G54 use preset work coordinate system 1 G55 use preset work coordinate system 2 G56 use preset work coordinate system 3 G57 use preset work coordinate system 4 G58 use preset work coordinate system 5 G59 use preset work coordinate system 6 G59.1 use preset work coordinate system 7 G59.2 use preset work coordinate system 8 G59.3 use preset work coordinate system 9

3.1. Default coordinate system

One other variable in the VAR file becomes important when we think about offset systems. This variable is named 5220. In the default files its value is set to 1.00000. This means that when the LinuxCNC starts up it should use the first coordinate system as its default. If you set this to 9.00000 it would use the ninth offset system as its default for start up and reset. Any value other than an integer (decimal really) between 1 and 9, or a missing 5220 variable will cause the LinuxCNC to revert to the default value of 1.00000 on start up.

3.2. Setting coordinate (fixture) offsets from G code

The G10 L2x command can be used to set coordinate (fixture) offsets: (these are just quick summaries, see the G code section for full details)

4. G92 Offsets

4.1. The G92 commands

This set of commands include;

-

G92 - This command, when used with axis names, sets values to offset variables.

-

G92.1 - This command sets zero values to the G92 variables.

-

G92.2 - This command suspends but does not zero out the G92 variables.

-

G92.3 - This command applies offset values that have been suspended.

When the commands are used as described above, they will work pretty much as you would expect.

To make the current point, what ever it is, have the coordinates X0, Y0, and Z0 you would use G92 X0 Y0 Z0. G92 does not work from absolute machine coordinates. It works from current location.

G92 also works from current location as modified by any other offsets that are in effect when the G92 command is invoked. While testing for differences between work offsets and actual offsets it was found that a G54 offset could cancel out a G92 and thus give the appearance that no offsets were in effect. However, the G92 was still in effect for all coordinates and did produce expected work offsets for the other coordinate systems.

It is a good practice to clear the G92 offsets at the end of their use with G92.1 or G92.2. When starting up LinuxCNC if any offsets are in the G92 variables they will be applied when an axis is homed.

4.2. Setting G92 values

There are at least two ways to set G92 values.

-

right mouse click on position displays of tkLinuxCNC will popup a window into which you can type a value.

-

the G92 command

Both of these work from the current location of the axis to which the offset is to be applied.

Issuing G92 X Y Z A B C U V W does in fact set values to the G92 variables such that each axis takes on the value associated with its name. These values are assigned to the current position of the machine axis. These results satisfy paragraphs one and two of the NIST document.

G92 commands work from current axis location and add and subtract correctly to give the current axis position the value assigned by the G92 command. The effects work even though previous offsets are in.

So if the X axis is currently showing 2.0000 as its position a G92 X0 will set an offset of -2.0000 so that the current location of X becomes zero. A G92 X2 will set an offset of 0.0000 and the displayed position will not change. A G92 X5.0000 will set an offset of 3.0000 so that the current displayed position becomes 5.0000.

4.3. G92 Cautions

Sometimes the values of a G92 offset will remain in the VAR file. This can happen when a file is aborted during processing that has G92 offsets in effect. When this happens reset or a startup will cause them to become active again.

The variables are named:

| Variable | Value |

|---|---|

5211 |

0.000000 |

5212 |

0.000000 |

5213 |

0.000000 |

5214 |

0.000000 |

5215 |

0.000000 |

5216 |

0.000000 |

where 5211 is the X axis offset and so on. If you are seeing unexpected positions as the result of a commanded move, as a result of storing an offset in a previous program and not clearing them at the end then issue a G92.1 in the MDI window to clear the stored offsets.

If G92 values exist in the VAR file when LinuxCNC starts up, the G92 values in the var file will be applied to the values of the current location of each axis. If this is home position and home position is set as machine zero everything will be correct. Once home has been established using real machine switches, or by moving each axis to a known home position and issuing an axis home command, any G92 offsets will be applied. If you have a G92 X1 in effect when you home the X axis the DRO will read X: 1.000 instead of the expected X: 0.000 because the G92 was applied to the machine origin. If you issue a G92.1 and the DRO now reads all zeros then you had a G92 offset in effect when you last ran LinuxCNC.

Unless your intention is to use the same G92 offsets in the next program, the best practice is to issue a G92.1 at the end of any G Code files where you use G92 offsets.

5. Sample Program Using Offsets

This sample engraving project mills a set of four .1 radius circles in roughly a star shape around a center circle. We can setup the individual circle pattern like this.

G10 L2 P1 X0 Y0 Z0 (ensure that G54 is set to machine zero) G0 X-0.1 Y0 Z0 G1 F1 Z-0.25 G3 X-0.1 Y0 I0.1 J0 G0 Z0 M2

We can issue a set of commands to create offsets for the four other circles like this.

G10 L2 P2 X0.5 (offsets G55 X value by 0.5 inch) G10 L2 P3 X-0.5 (offsets G56 X value by -0.5 inch) G10 L2 P4 Y0.5 (offsets G57 Y value by 0.5 inch) G10 L2 P5 Y-0.5 (offsets G58 Y value by -0.5 inch)

We put these together in the following program:

(a program for milling five small circles in a diamond shape) G10 L2 P1 X0 Y0 Z0 (ensure that G54 is machine zero) G10 L2 P2 X0.5 (offsets G55 X value by 0.5 inch) G10 L2 P3 X-0.5 (offsets G56 X value by -0.5 inch) G10 L2 P4 Y0.5 (offsets G57 Y value by 0.5 inch) G10 L2 P5 Y-0.5 (offsets G58 Y value by -0.5 inch) G54 G0 X-0.1 Y0 Z0 (center circle) G1 F1 Z-0.25 G3 X-0.1 Y0 I0.1 J0 G0 Z0 G55 G0 X-0.1 Y0 Z0 (first offset circle) G1 F1 Z-0.25 G3 X-0.1 Y0 I0.1 J0 G0 Z0 G56 G0 X-0.1 Y0 Z0 (second offset circle) G1 F1 Z-0.25 G3 X-0.1 Y0 I0.1 J0 G0 Z0 G57 G0 X-0.1 Y0 Z0 (third offset circle) G1 F1 Z-0.25 G3 X-0.1 Y0 I0.1 J0 G0 Z0 G58 G0 X-0.1 Y0 Z0 (fourth offset circle) G1 F1 Z-0.25 G3 X-0.1 Y0 I0.1 J0 G54 G0 X0 Y0 Z0 M2

Now comes the time when we might apply a set of G92 offsets to this program. You’ll see that it is running in each case at Z0. If the mill were at the zero position, a G92 Z1.0000 issued at the head of the program would shift everything down an inch. You might also shift the whole pattern around in the XY plane by adding some X and Y offsets with G92. If you do this you should add a G92.1 command just before the m2 that ends the program. If you do not, other programs that you might run after this one will also use that G92 offset. Furthermore it would save the G92 values when you shut down the LinuxCNC and they will be recalled when you start up again.