Halshow

The script halshow can help you find your way around a running HAL. This is a very specialized system and it must connect to a working HAL. It cannot run standalone because it relies on the ability of HAL to report what it knows of itself through the halcmd interface library. It is discovery based. Each time halshow runs with a different LinuxCNC configuration it will be different.

As we will soon see, this ability of HAL to document itself is one key to making an effective CNC system.

1. Starting Halshow

Halshow is in the AXIS menu under Machine/Show HAL Configuration.

Halshow is in the TkLinuxCNC menu under Scripts/HAL Show.

2. HAL Tree Area

At the left of its display as shown in figure is a tree view, somewhat like you might see with some file browsers. At the right is a tabbed notebook with tabs for show and watch.

The tree shows all of the major parts of a HAL. In front of each is a small plus (+) or minus (-) sign in a box. Clicking the plus will expand that tree node to display what is under it. If that box shows a minus sign, clicking it will collapse that section of the tree.

You can also expand or collapse the tree display using the Tree View menu at the upper left edge of the display. Under Tree View you will find: Expand Tree, Collapse Tree; Expand Pins, Expand Parameters, Expand Signals; and Erase Watch. (Note that Erase Watch erases all previously set watches, you cannot erase just one watch.)

3. HAL Show Area

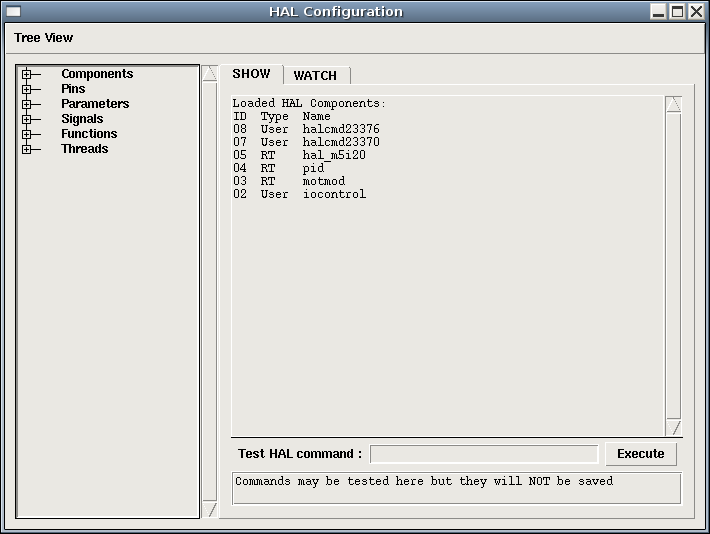

Clicking on the node name, the word "Components" for example, will show you (under the "Show" tab) all that HAL knows about the contents of that node. Figure [cap:halshow-layout] shows a list exactly like you will see if you click the "Components" name while you are running a standard m5i20 servo card. The information display is exactly like those shown in traditional text based HAL analysis tools. The advantage here is that we have mouse click access, access that can be as broad or as focused as you need.

If we take a closer look at the tree display we can see that the six major parts of a HAL can all be expanded at least one level. As these levels are expanded you can get more focused with the reply when you click on the rightmost tree node. You will find that there are some HAL pins and parameters that show more than one reply. This is due to the nature of the search routines in halcmd itself. If you search one pin you may get two, like this:

Component Pins: Owner Type Dir Value Name 06 bit -W TRUE parport.0.pin-10-in 06 bit -W FALSE parport.0.pin-10-in-not

The second pin’s name contains the complete name of the first.

Below the show area on the right is a set of widgets that will allow you to play with the running HAL. The commands you enter here and the effect that they have on the running HAL are not saved. They will persist as long as LinuxCNC remains up but are gone as soon as LinuxCNC is.

The entry box labeled "Test HAL Command:" will accept any of the commands listed for halcmd. These include:

-

loadrt, unloadrt (load/unload real-time module)

-

loadusr, unloadusr (load/unload user-space component)

-

addf, delf (add/delete a function to/from a real-time thread)

-

net (create a connection between two or more items)

-

setp (set parameter (or pin) to a value)

This little editor will enter a command any time you press <enter> or push the execute button. An error message from halcmd will show below this entry widget when these commands are not properly formed. If you are not certain how to set up a proper command you’ll need to read again the documentation on halcmd and the specific modules that you are working with.

Let’s use this editor to add a differential module to a HAL and connect it to axis position so that we could see the rate of change in position, i.e., acceleration. We first need to load a HAL component named ddt, add it to the servo thread, then connect it to the position pin of a joint. Once that is done we can find the output of the differentiator in halscope. So let’s go. (Yes, I looked this one up.)

loadrt ddt

Now look at the components node and you should see ddt in there someplace.

Loaded HAL Components: ID Type Name 10 User halcmd29800 09 User halcmd29374 08 RT ddt 06 RT hal_parport 05 RT scope_rt 04 RT stepgen 03 RT motmod 02 User iocontrol

Sure enough there it is. Notice that its ID is 08. Next we need to find out what functions are available with it so we look at functions:

Exported Functions: Owner CodeAddr Arg FP Users Name 08 E0B97630 E0DC7674 YES 0 ddt.0 03 E0DEF83C 00000000 YES 1 motion-command-handler 03 E0DF0BF3 00000000 YES 1 motion-controller 06 E0B541FE E0DC75B8 NO 1 parport.0.read 06 E0B54270 E0DC75B8 NO 1 parport.0.write 06 E0B54309 E0DC75B8 NO 0 parport.read-all 06 E0B5433A E0DC75B8 NO 0 parport.write-all 05 E0AD712D 00000000 NO 0 scope.sample 04 E0B618C1 E0DC7448 YES 1 stepgen.capture-position 04 E0B612F5 E0DC7448 NO 1 stepgen.make-pulses 04 E0B614AD E0DC7448 YES 1 stepgen.update-freq

Here we look for owner #08 and see a function named ddt.0. We should be able to add ddt.0 to the servo thread and it will do its math each time the servo thread is updated. Once again we look up the addf command and find that it uses three arguments like this:

addf <functname> <threadname> [<position>]

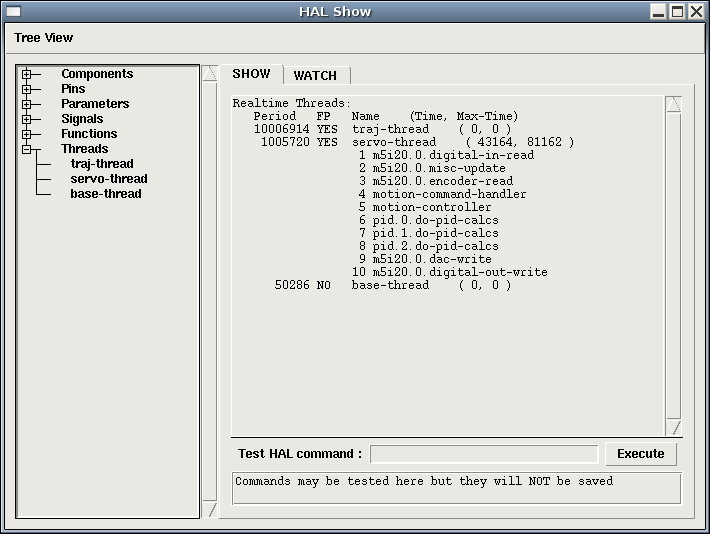

We already know the functname=ddt.0 so let’s get the thread name right by expanding the thread node in the tree. Here we see two threads, servo-thread and base-thread. The position of ddt.0 in the thread is not critical. So we add the function ddt.0 to the servo-thread:

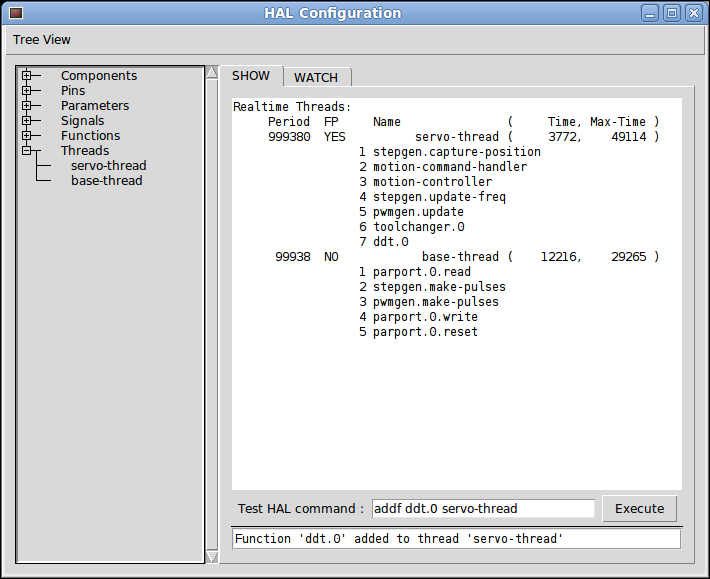

addf ddt.0 servo-thread

This is just for viewing, so we leave position blank and get the last position in the thread. The following figure shows the state of halshow after this command has been issued.

Next we need to connect ddt to something. But how do we know what pins are available? The answer is to look under pins. There we find ddt and see this:

Component Pins: Owner Type Dir Value Name 08 float R- 0.00000e+00 ddt.0.in 08 float -W 0.00000e+00 ddt.0.out

That looks easy enough to understand, but what signal or pin do we want to connect to it? It could be an axis pin, a stepgen pin, or a signal. We see this when we look at joint.0:

Component Pins: Owner Type Dir Value Name 03 float -W 0.00000e+00 joint.0.motor-pos-cmd ==> Xpos-cmd

So it looks like Xpos-cmd should be a good signal to use. Back to the editor where we enter the following command:

linksp Xpos-cmd ddt.0.in

Now if we look at the Xpos-cmd signal using the tree node we’ll see what we’ve done:

Signals: Type Value Name float 0.00000e+00 Xpos-cmd <== joint.0.motor-pos-cmd ==> ddt.0.in ==> stepgen.0.position-cmd

We see that this signal comes from joint.o.motor-pos-cmd and goes to both ddt.0.in and stepgen.0.position-cmd. By connecting our block to the signal we have avoided any complications with the normal flow of this motion command.

The HAL Show Area uses halcmd to discover what is happening in a running HAL. It gives you complete information about what it has discovered. It also updates as you issue commands from the little editor panel to modify that HAL. There are times when you want a different set of things displayed without all of the information available in this area. That is where the HAL Watch Area is of value.

4. Watch Tab

Clicking the watch tab produces a blank canvas. You can add signals and pins

to this canvas and watch their values.

[The refresh rate of the watch

display is much lower than Halmeter or Halscope. If you need good resolution

of the timing of signals those tools are much more effective.]

You can add

signals or pins when the watch tab is displayed by clicking on the name of it.

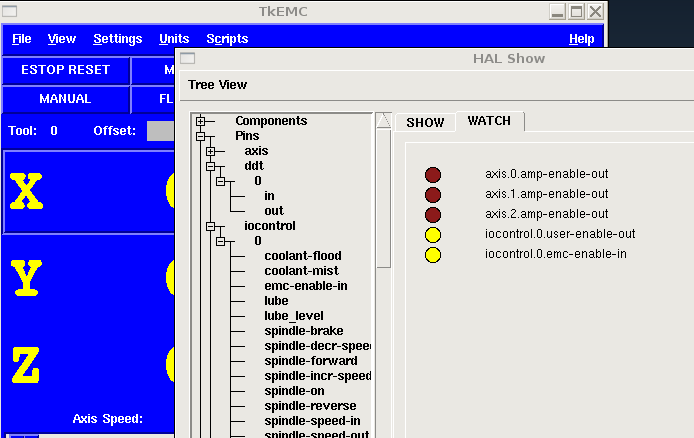

The following figure shows this canvas with several "bit" type signals. These

signals include enable-out for the first three axes and two of the three

iocontrol "estop" signals. Notice that the axes are not enabled even though the

estop signals say that LinuxCNC is not in estop. A quick look at TkLinuxCNC

shows that the condition of LinuxCNC is ESTOP RESET. The amp enables do not

turn true until the machine has been turned on.

Watch displays bit type (binary) values using colored circles representing LEDs. They show as dark brown when a bit signal or pin is false, and as light yellow whenever that signal is true. If you select a pin or signal that is not a bit type (binary) signal, watch will show it as a numerical value.

Watch will quickly allow you to test switches or see the effect of changes that you make to LinuxCNC while using the graphical interface. Watch’s refresh rate is a bit slow to see stepper pulses, but you can use it for these if you move an axis very slowly or in very small increments of distance. If you’ve used IO_Show in LinuxCNC, the watch page in halshow can be set up to watch a parport much as IO_Show did.